Method for testing and evaluating attrition degree of packing film for cigarette

An evaluation method and packaging film technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of large influence of human factors, slow research progress, and large influence of human factors on test results, and achieve the effect of easy promotion and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Cut a piece of BOPP film for cigarettes into a size of 20cm*30cm, and use an ink rubbing instrument to grind the surface of the film;

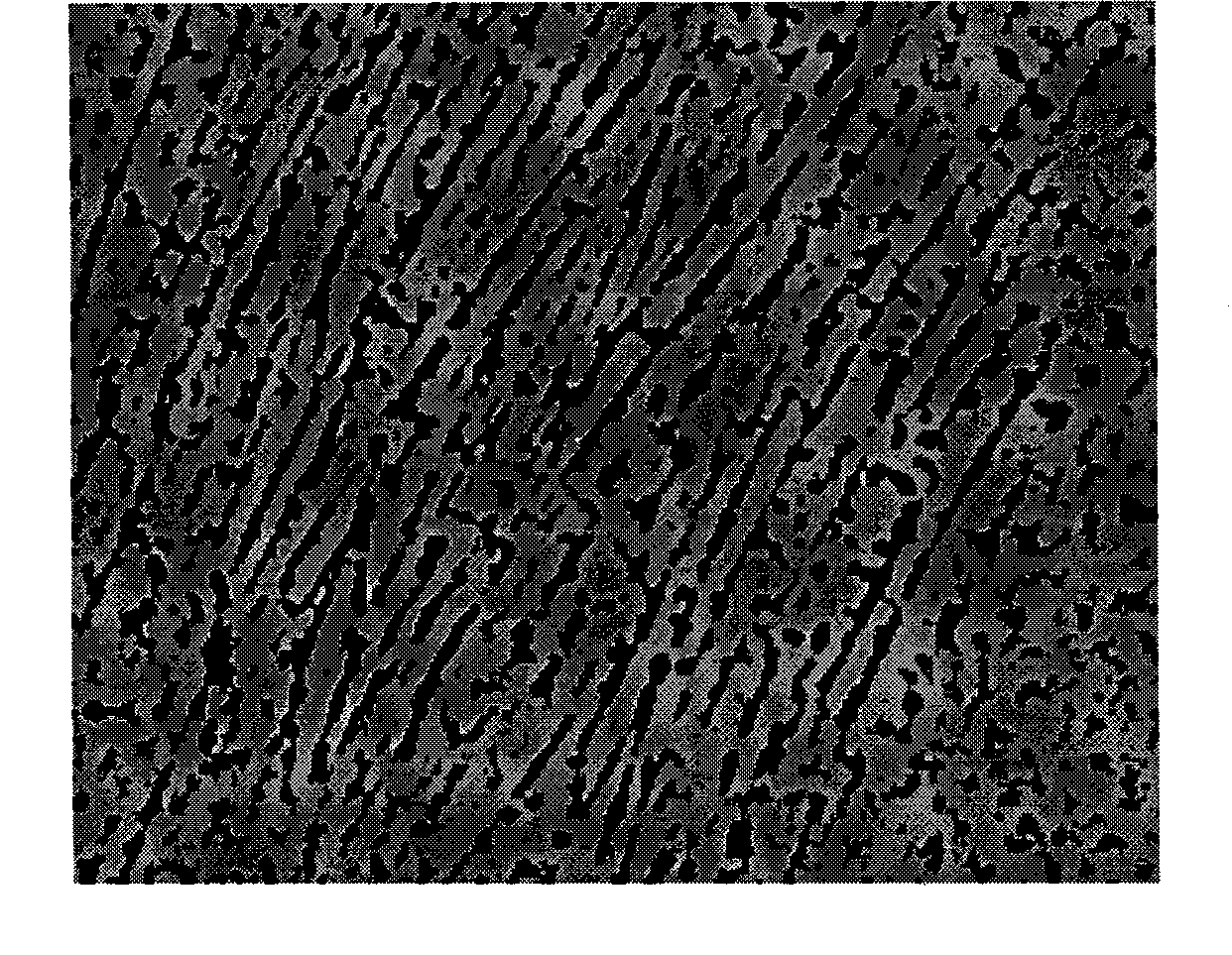

[0035] 2. Paste the scratched sample on a smooth polymer material base plate, use ink to dye the surface of the film, use lens cleaning paper to gently wipe off the ink on the film surface, and control the strength when wiping to ensure the scratched area be dyed;

[0036] 3. Use a digital camera to photograph the dyed sample obtained in step 2 to obtain a photo;

[0037] 4. Use image processing software to adjust the color and contrast of the photo obtained in step 3, highlighting the color of the polished area after dyeing;

[0038] 5. Use image analysis software to perform area calculation on the image processed in step 4 to obtain the area of the grinding area;

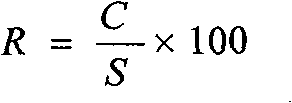

[0039] 6. Divide the abrasion area area obtained in step 5 by the total area of the test sample to obtain the abrasion area ratio of the sample, and use the abrasi...

Embodiment 2

[0041] 1. Cut a piece of BOPP film for cigarettes into a size of 20cm*30cm, and use a film friction meter to grind the surface of the film;

[0042] 2. Paste the polished sample on a smooth ceramic base plate, use colored pigments to dye the surface of the film, use a soft cloth to gently wipe off the remaining colored pigments on the surface of the film, and control the strength when wiping to ensure grinding the area is stained;

[0043] 3. Use a scanner to scan the dyed sample obtained in step 2 to obtain a photo;

[0044] 4. Use image processing software to adjust the color and contrast of the photo obtained in step 3, highlighting the color of the polished area after dyeing;

[0045] 5. Use image analysis software to perform area calculation on the image processed in step 4 to obtain the area of the grinding area;

[0046] 6. Divide the abrasion area area obtained in step 5 by the total area of the test sample to obtain the abrasion area ratio of the sample, and use...

Embodiment 3

[0048] 1. Gently remove the abrasive film from a small cigarette box, cut the film according to the size of the label paper on the front of the small box, and prepare a sample;

[0049] 2. Paste the sample on a smooth metal floor, use pigments to dye the surface of the film, use a cotton ball to gently wipe off the excess pigment on the surface of the film, and control the strength when wiping to ensure that the scratched area is dyed;

[0050] 3. Use a digital video camera to photograph the dyed sample obtained in step 2 to obtain a photo;

[0051] 4. Use image processing software to adjust the color and contrast of the photo obtained in step 3, highlighting the color of the polished area after dyeing;

[0052] 5. Use image analysis software to perform area calculation on the image processed in step 4 to obtain the area of the grinding area;

[0053]6. Divide the abrasion area area obtained in step 5 by the total area of the test sample to obtain the abrasion area ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com