Precision detection device and method for multi-core cable terminal crimping quality

A technology of cable terminal and crimping quality, applied in the direction of measuring device, measuring electrical variable, measuring electricity, etc., can solve the problems of unable to meet the requirements, unable to measure the equivalent resistance value of the core wire, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

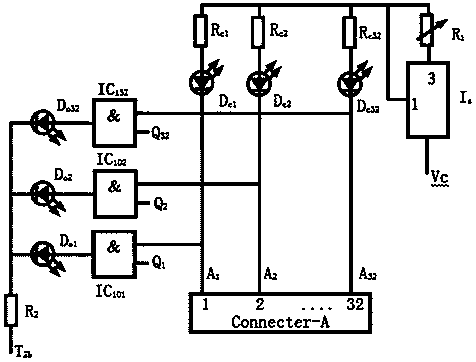

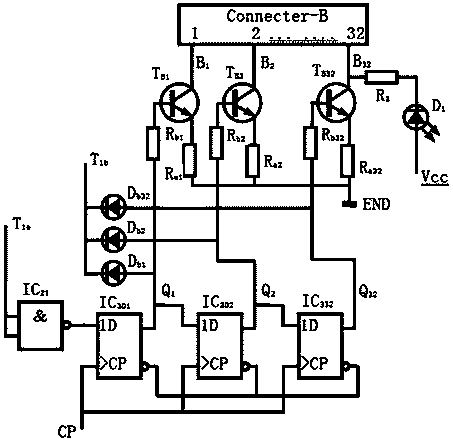

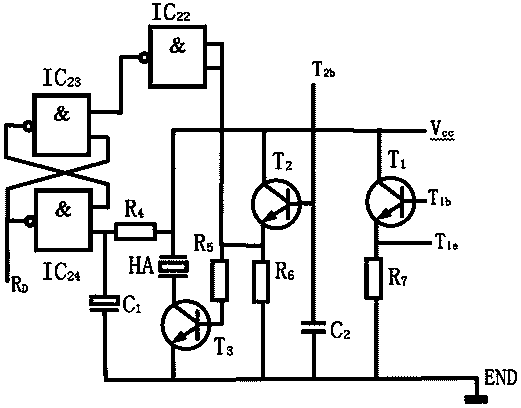

[0074] Such as figure 2 As shown, a multi-core cable terminal crimping quality precision detection device, including: detection speed control circuit 1, the detection speed control circuit 1 is connected to the detection timing control circuit 2, the detection timing control circuit 2 is misaligned with the open circuit The detection circuit 3 is connected, and the open circuit dislocation detection circuit 3 is connected with the fault judgment alarm circuit 6; the detection timing control circuit 2 is also connected with the sampling comparison amplifier circuit 4, and the sampling comparison amplifier circuit 4 is connected with the A / D analog-to-digital conversion The circuit 7 is connected, and the A / D analog-to-digital conversion circuit 7 is connected with the storage / count control circuit 8 and the CPU processing unit 5 respectively, and the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com