Concentric type double-motor control wrapping machine

A dual-motor, concentric technology, applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve problems such as easy to generate vibration, easy to generate vibration, and not firm, so as to improve the quality of tape, overcome friction, and rotate high speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

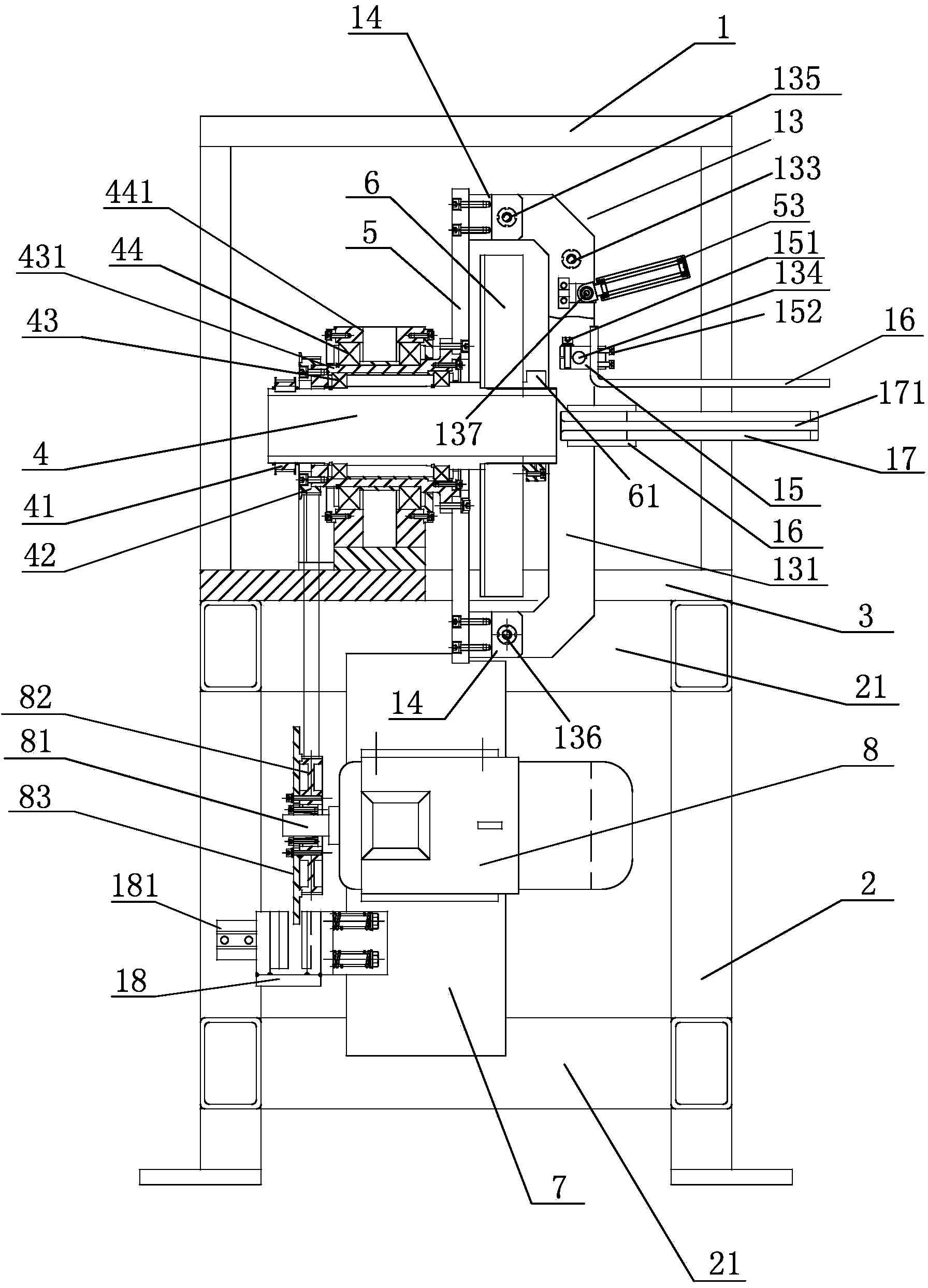

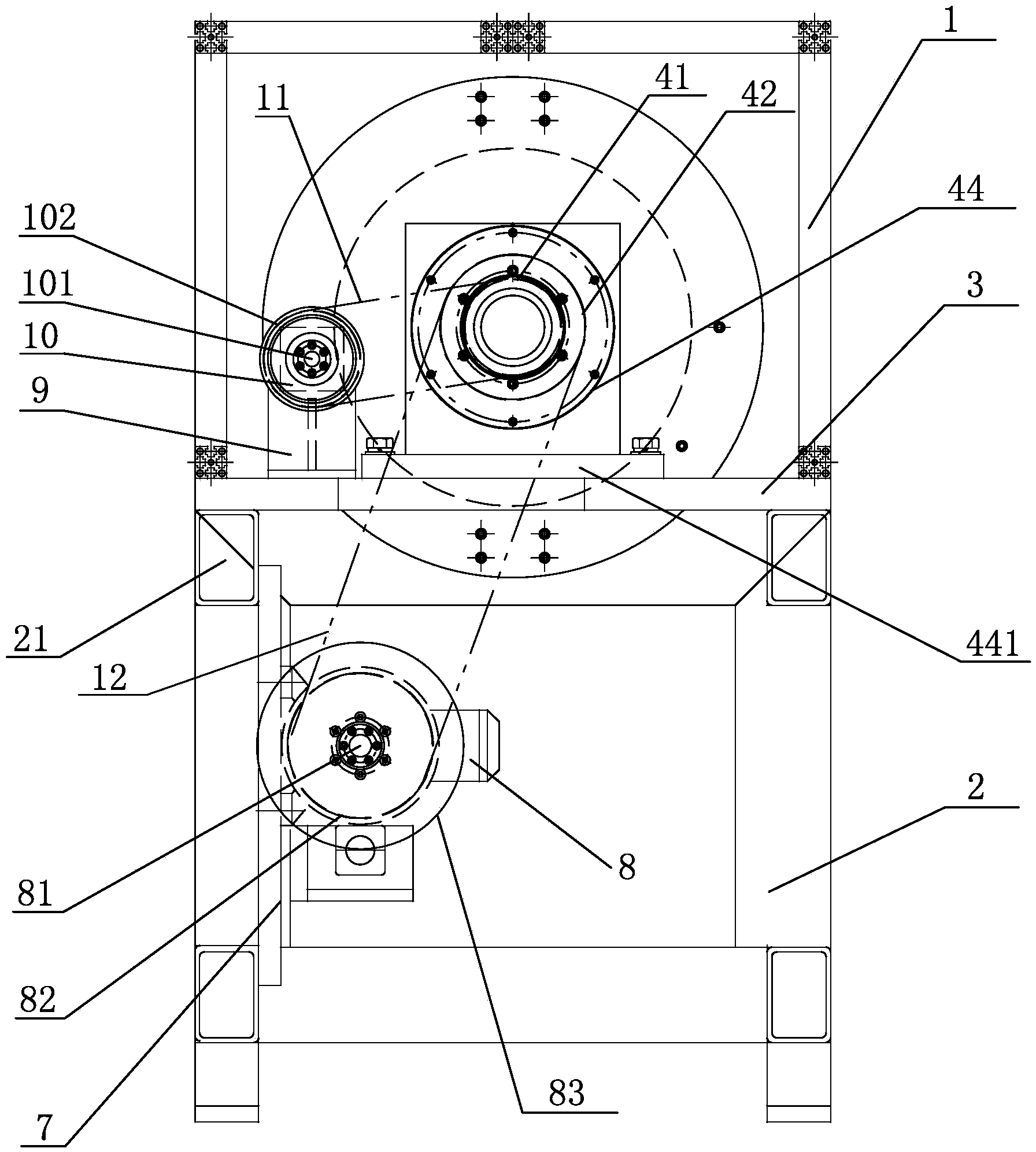

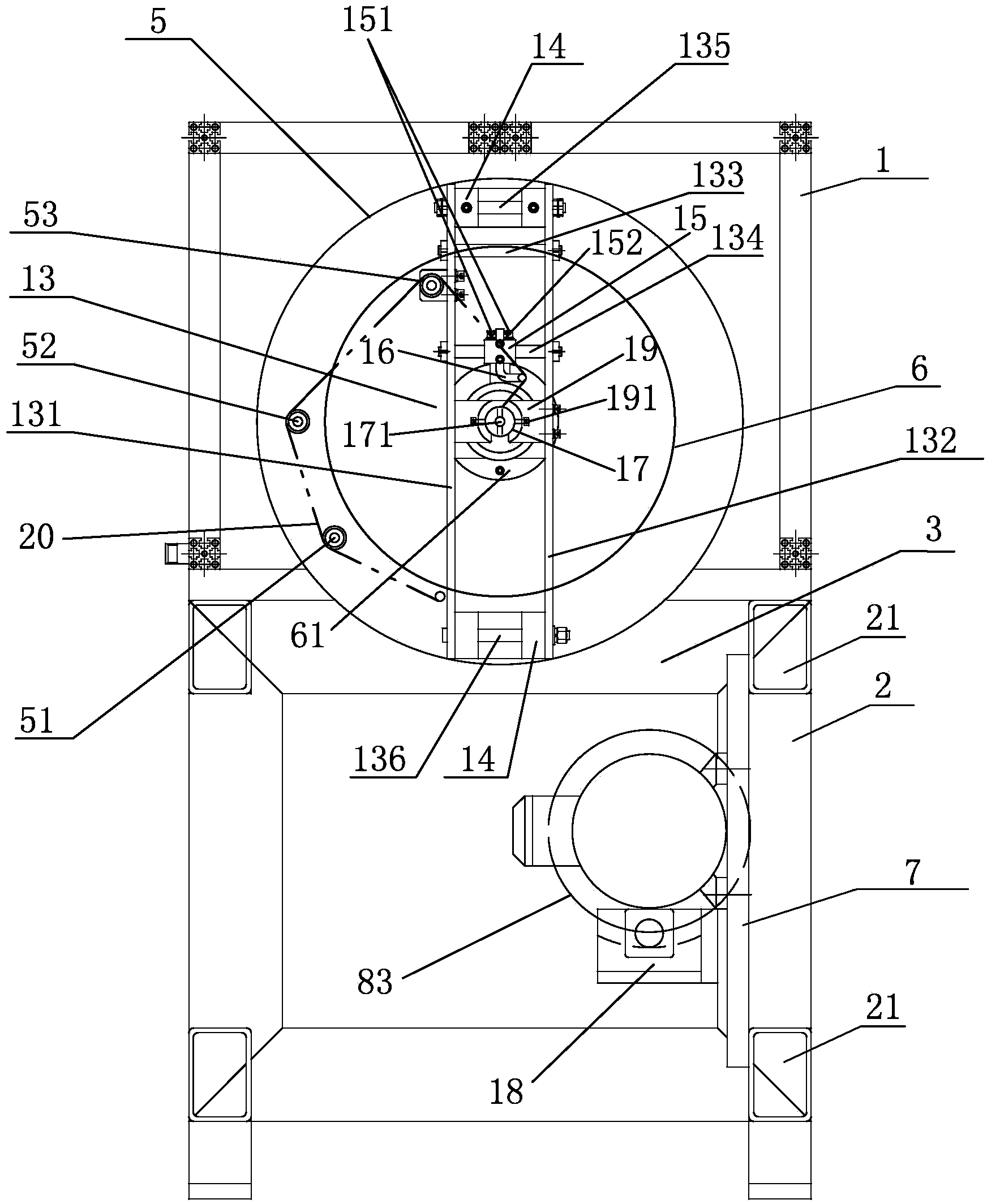

[0022] Such as figure 1 As shown, the concentric dual-motor control wrapping machine of the present invention includes a protective cover 1 located above and a base 2 located below. The main shaft 4 arranged horizontally in its length direction, the left end of the main shaft 4 is vertically fixed with a first belt pulley 41, and the right side of the first belt pulley 41 is equipped with a second belt pulley 42, and the wheel diameter of the first belt pulley 41 is smaller than that of the first belt pulley 41. The wheel diameter of two pulleys 42. Main shaft 4 is also provided with inner bearing 43, outer bearing 44, and the inner bearing seat 431, outer bearing seat 441 that cooperates with inner bearing 43, outer bearing 44, inner bearing 43, outer bearing 44, inner bearing seat 431, outer bearing The seat 441 is located between the second pulley 42 and the rotating disk 5, and the outer bearing seat 441 is fixed on the fixed plate 3 to ensure that when the wrapping machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com