Soaking method of tobacco leaves

A technology of tobacco leaves and soaking box, which is applied in the fields of tobacco, tobacco processing, application, etc., can solve the problems of heavy miscellaneous gas, poor flue gas quality, and high proportion of miscellaneous gas smoke, so as to improve the utilization rate, solve the shortage of raw materials, and reduce nicotine. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

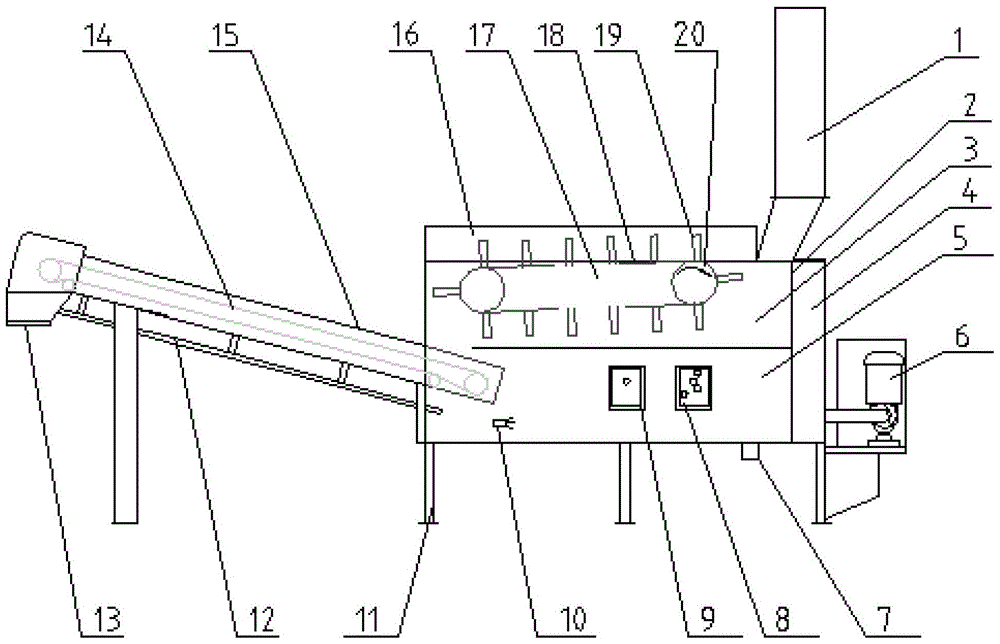

[0036] Such as figure 1 Shown, the steeping device of the tobacco leaf that the present invention adopts comprises box body, and the top of box body is provided with loam cake 16, and loam cake 16 is used to prevent steam from overflowing; One side of loam cake 16 is provided with feed cover 1, feed material The cover 1 communicates with the box body; the bottom of the box body is provided with a drain pipe 7; the box body is supported by the machine base 11;

[0037] A transverse partition is arranged horizontally in the box, and the transverse partition divides the box into upper and lower parts connected to each other, the upper part is the soaking tank 3, and the lower part is the hot water tank 5;

[0038] One side of the box is connected to the buffer tank 4 through the vertical partition 2, and the buffer tank 4 is connected to the water pump 6 through the pipeline;

[0039] The upper part of the vertical partition 2 is provided with a plurality of small holes, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com