A smart locker based on mcu

A locker and intelligent technology, applied in the field of lockers, can solve the problems of hindering the placement of items, the scale of the lifting device is large, and it is difficult to improve the aesthetic feeling, and achieves the effect of simple appearance, safe use, and increased space utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] See attached Figure 4 , Figure 19~Figure 21 . Detect if a key is pressed. When button 16 on the control panel, a certain drawer button is pressed, a P1 port of the AT89C51 connected to the button becomes low level, and at this moment, the drawer layer to be opened will be displayed on the LCD display. The MCU detects the pressed drawer layer through the query method, and the software programming jumps to the motor execution program.

Embodiment 2

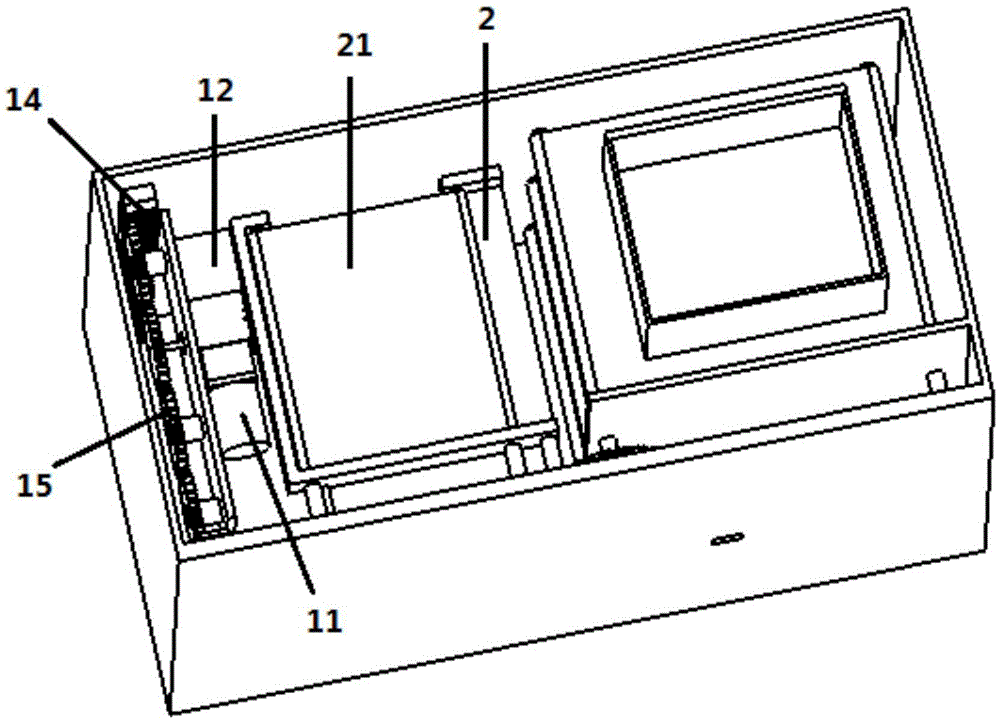

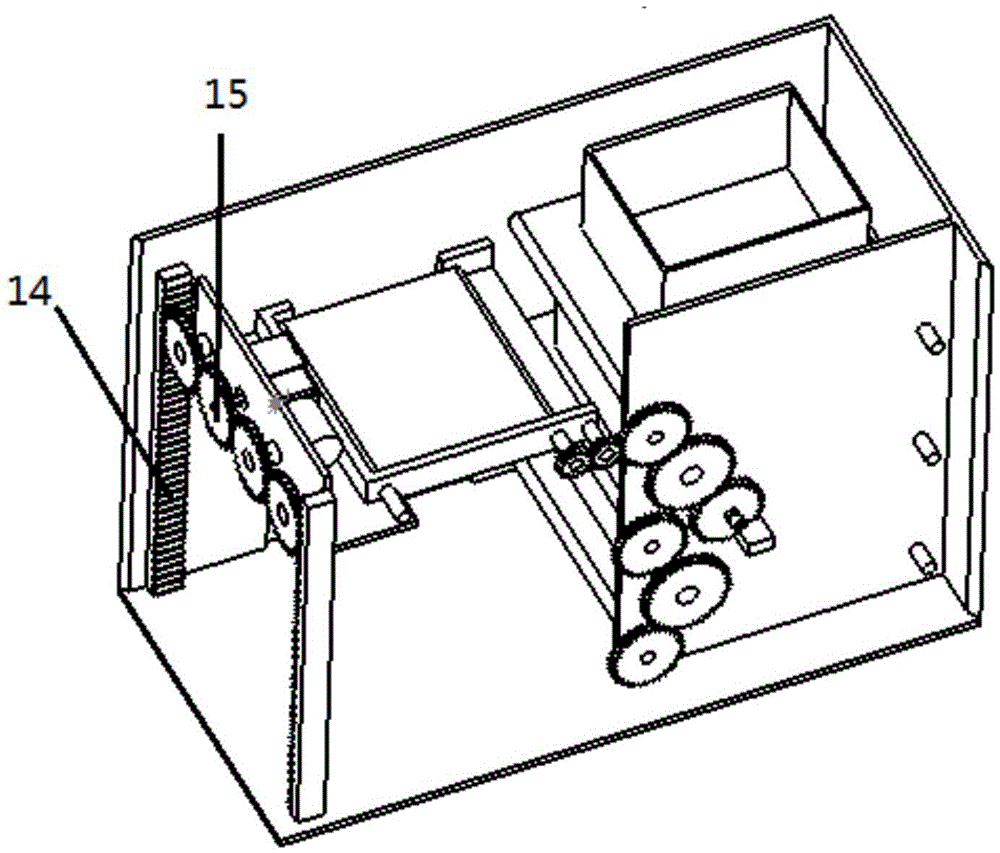

[0068] See attached Figure 1~Figure 2 . Lifting plate 2 falls vertically to place conveyor belt 5 ahead. The P3.4~P3.7 pins of the chip AT89C51 output PWM control signals. The ULN2003 chip controls the rotation of the lifting motor 11. The worm 18 coaxial with the lifting motor 11 drives the turbine 19 to rotate. The turbine 19 is coaxial with a lifting gear 15. Lifting gear 15 rotates and drives the gear meshed with it to rotate in the opposite direction, and lifting plate 2 vertically falls to the place ahead of the corresponding conveyor belt 5, and lifting plate 2 maintains the same level as the corresponding placing conveyor belt 5. At this time, the chip AT89C51 outputs a delay signal and waits for the drawer 4 to move to the lifting plate 2. In order to fix the lifting gear 15, the worm gear 12 is used to realize self-locking, because the thread opening angle of the worm 18 is small, which is smaller than the pressure angle of the worm gear 19. , so the worm wheel 19...

Embodiment 3

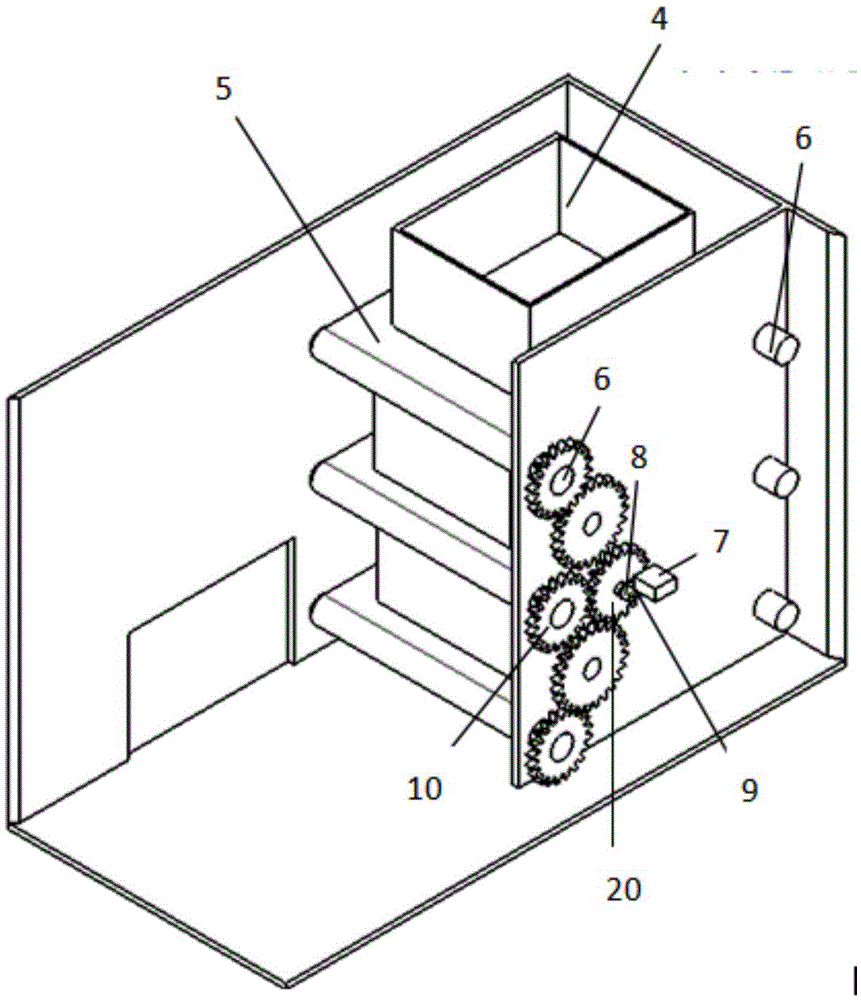

[0070] See attached image 3 , Figure 6 , Figure 17 , Figure 18 . The drawer 4 is moved onto the lifting plate 2 by placing the conveyor belt 5 and the lifting plate conveyor belt 21 . The P2.7 pin of the chip AT89C51 first outputs a control signal to control the rotation angle of the steering gear 7. The steering gear 7 adjusts the position of the transmission motor 8 and the positioning gear 20 through the swing arm 9, so that the positioning gear 20 meshes with the corresponding transmission gear 10 , when the positioning gear 20 meshes with the transmission gear 10, the P3.0~P3.3 pins output PWM control signals, and the ULN2003 chip controls the rotation of the transmission motor 8, and the output shaft of the transmission motor 8 is coaxially connected with the positioning gear 20 to drive the positioning The gear 20 rotates, and the transmission gear 10 rotates to drive the placement conveyor belt 5 to move, and the drawer 4 moves forward on the placement conveyor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com