Adsorbing fixture and workpiece machining method thereof

A jig and adsorption cavity technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of complex structure, high cost and large volume, and achieve the effects of simple operation, low cost and simple structure of the jig.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

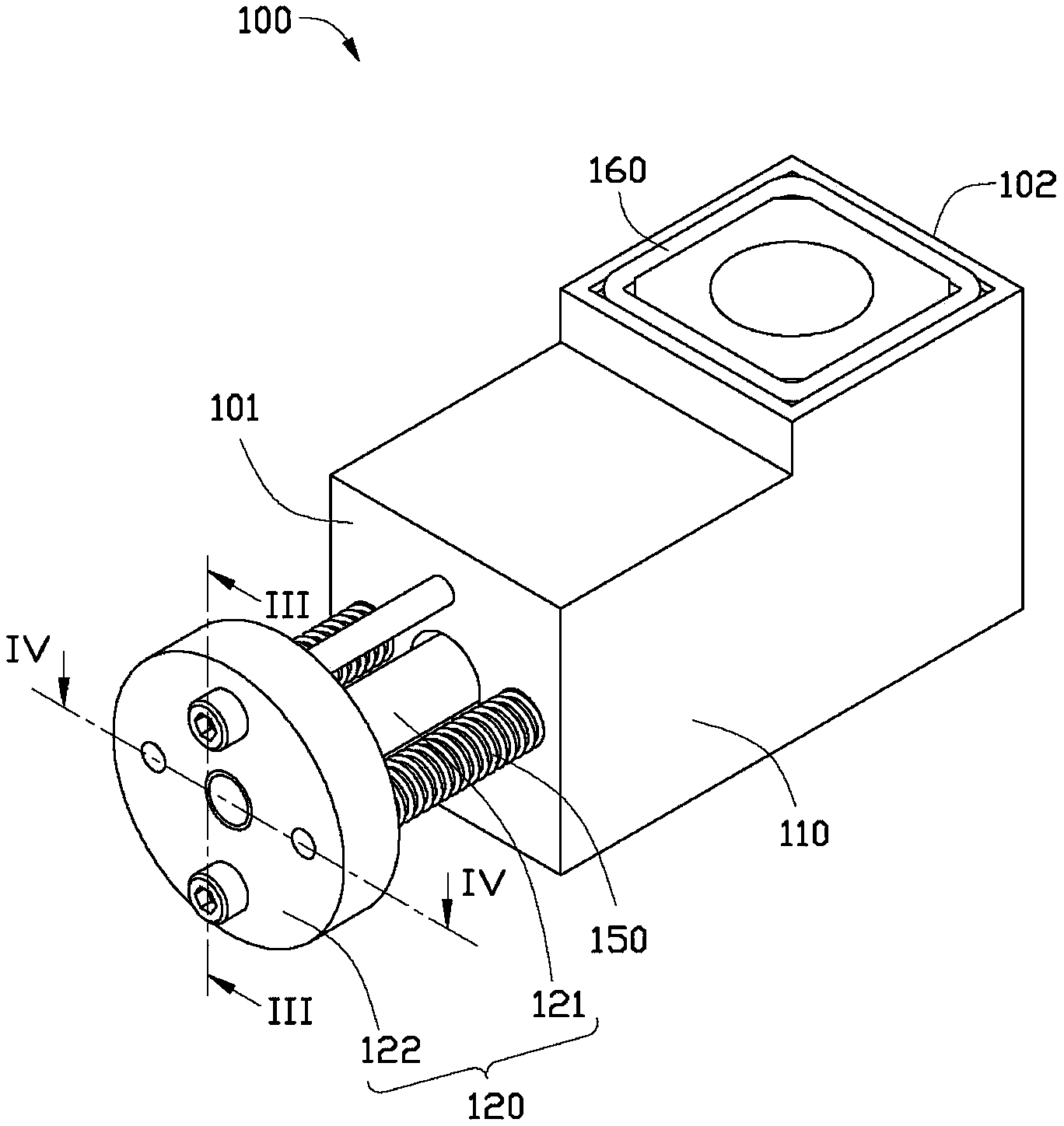

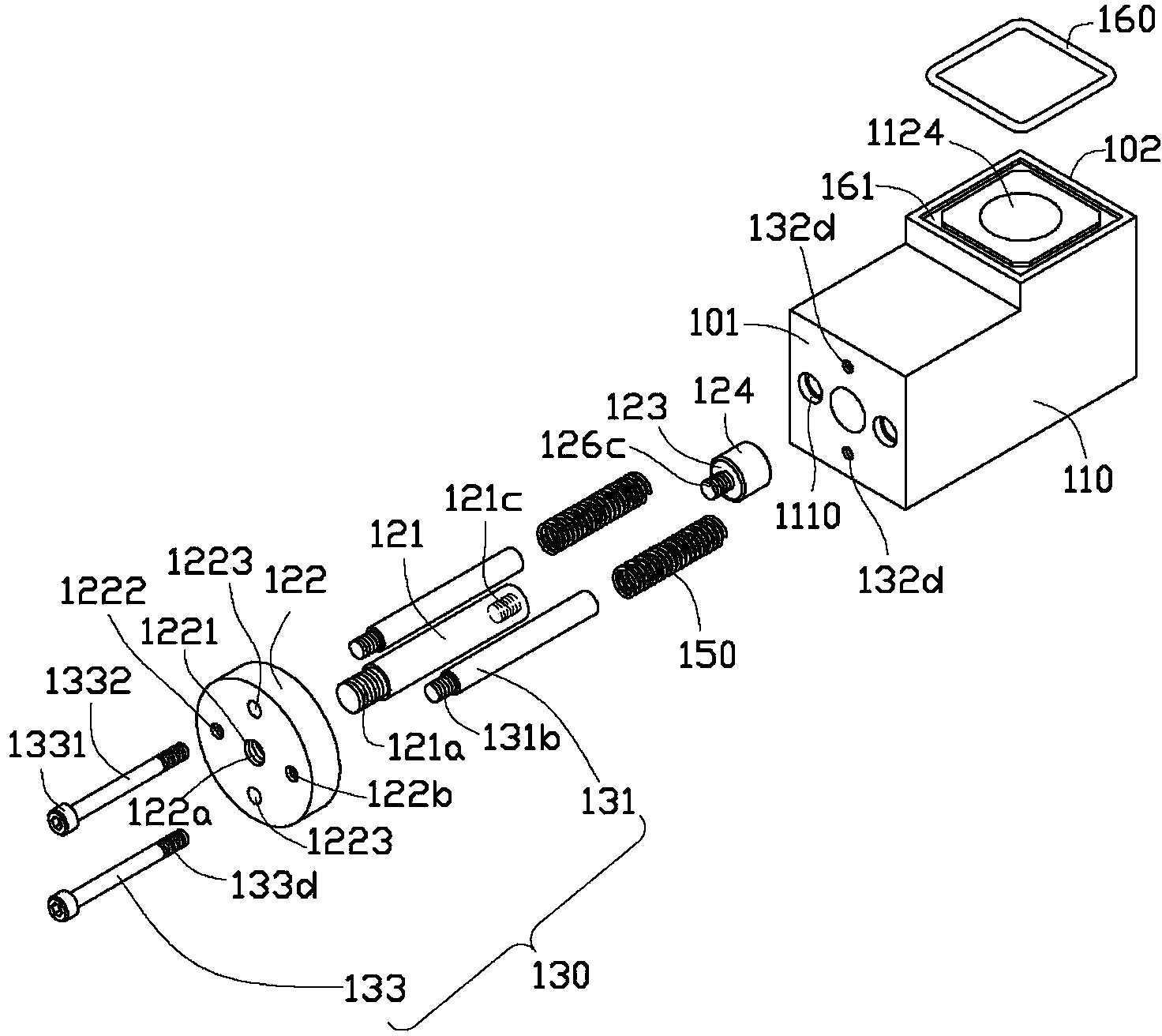

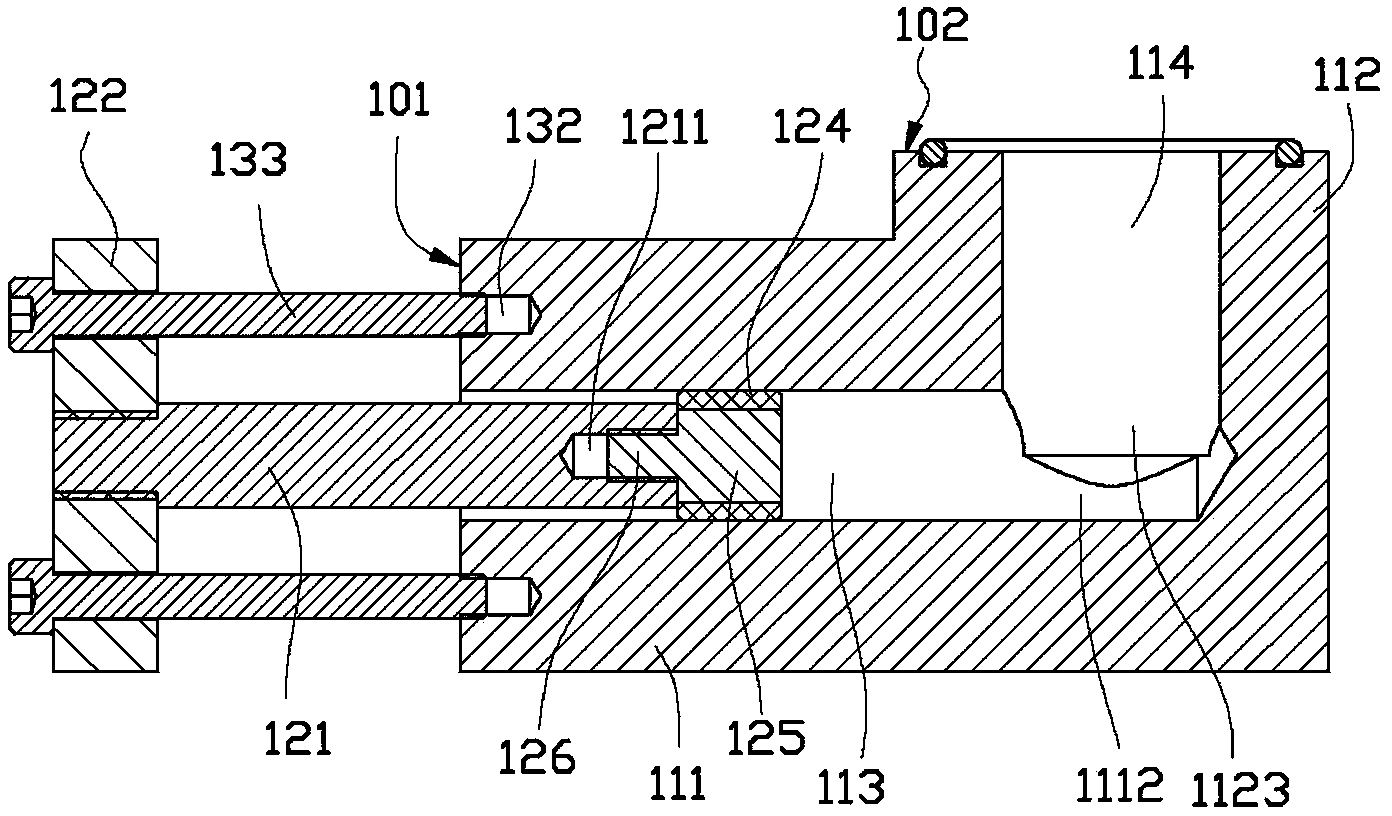

[0015] see Figure 1 to Figure 4 , The adsorption jig 100 of the preferred embodiment of the present invention includes a cylinder body 110 , a piston 120 , a positioning unit 130 and an elastic element 150 .

[0016] The barrel 110 includes a first barrel 111 and a second barrel 112 , and the first barrel 111 is connected to the second barrel 112 . In this embodiment, the shape of the first cylinder 111 is a cuboid, which has a first end surface 101, and the first end surface 101 is provided with a first adsorption chamber 113, two guide holes 1110 and two positioning screw holes 132. In this embodiment, the first adsorption cavity 113 is a cylindrical hole with a central axis perpendicular to the first end surface 101 . The two guide holes 1110 are also cylindrical holes whose central axis is perpendicular to the first end surface 101, and the two guide holes 1110 are respectively located on opposite sides of the first adsorption chamber 113. In this embodiment, A line co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com