Clamping device for small-sized rod-type elastic part

A technology for clamping devices and parts, applied in the direction of workpiece clamping devices, manufacturing tools, etc., to achieve the effect of firm clamping, simple structure, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

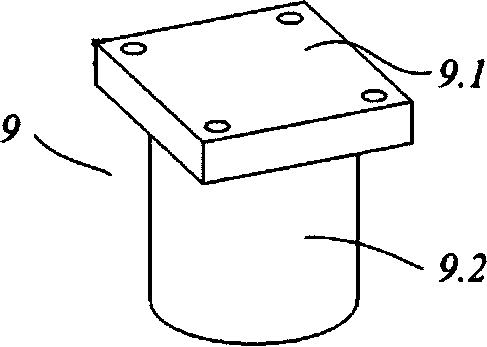

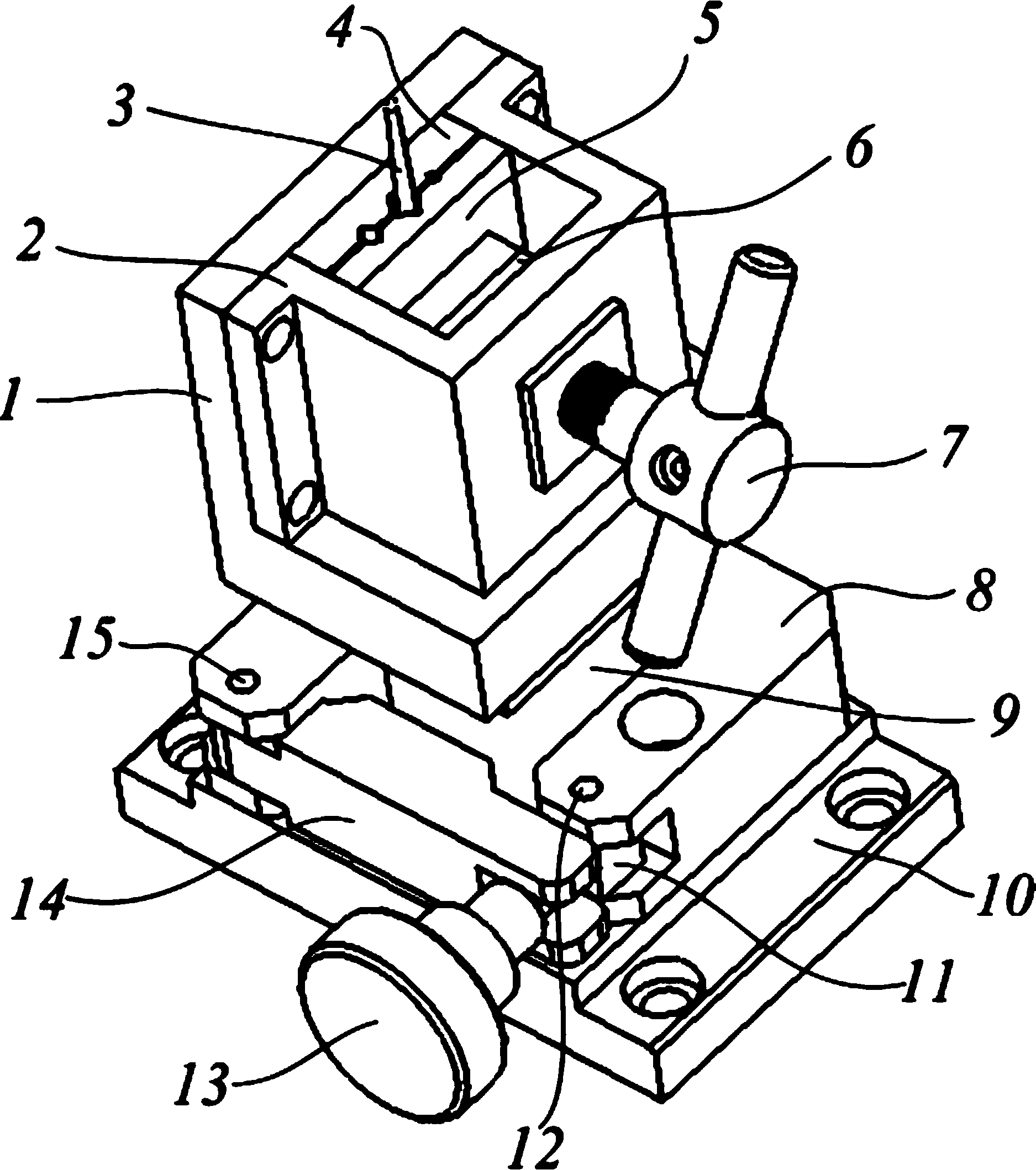

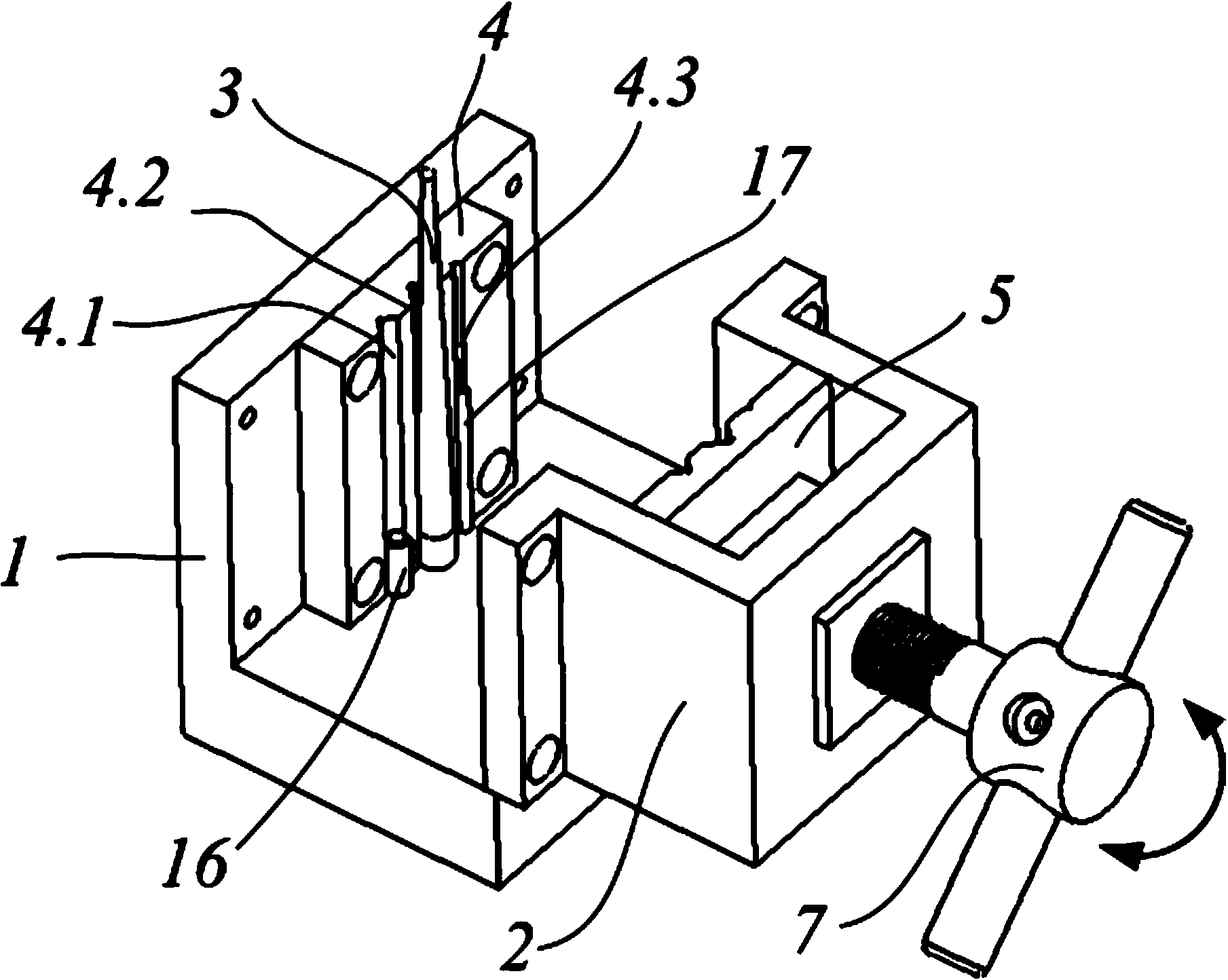

[0044] like figure 1 As shown, it is a schematic diagram of the mechanism of the small precision rod-type elastic part clamping device of the present invention, including a V-shaped groove clamp base 1, a screw support shell 2, a rod-type elastic part 3, a V-shaped groove clamp block fixed end 4, and a V-shaped Groove clamp block movable block 5, briquetting block 6, rotary screw rod 7, U-shaped block 8, columnar support base 9, fixed base 10 and gate type briquetting block 14. The V-shaped groove clamp fixed end 4 and the V-shaped groove clamp movable block 5 are installed side by side in the screw support shell 2, and one end of the rotating screw 7 is connected with the V-shaped groove clamp movable block 5 through the threaded hole on the screw support shell 2, And the two are fixedly connected by the briquetting block 6 . The V-shaped groove clip movable block 5 can realize linear reciprocating movement in the screw rod support shell 2 along with the rotation of the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com