Mini roller press

A technology of roller presses and miniature rollers, which is applied in the direction of presses, material forming presses, manufacturing tools, etc., which can solve the problems of larger device size, increased installation area, and equipment operation failures, and achieve simple maintenance operations, Effect of reducing device failure and large load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

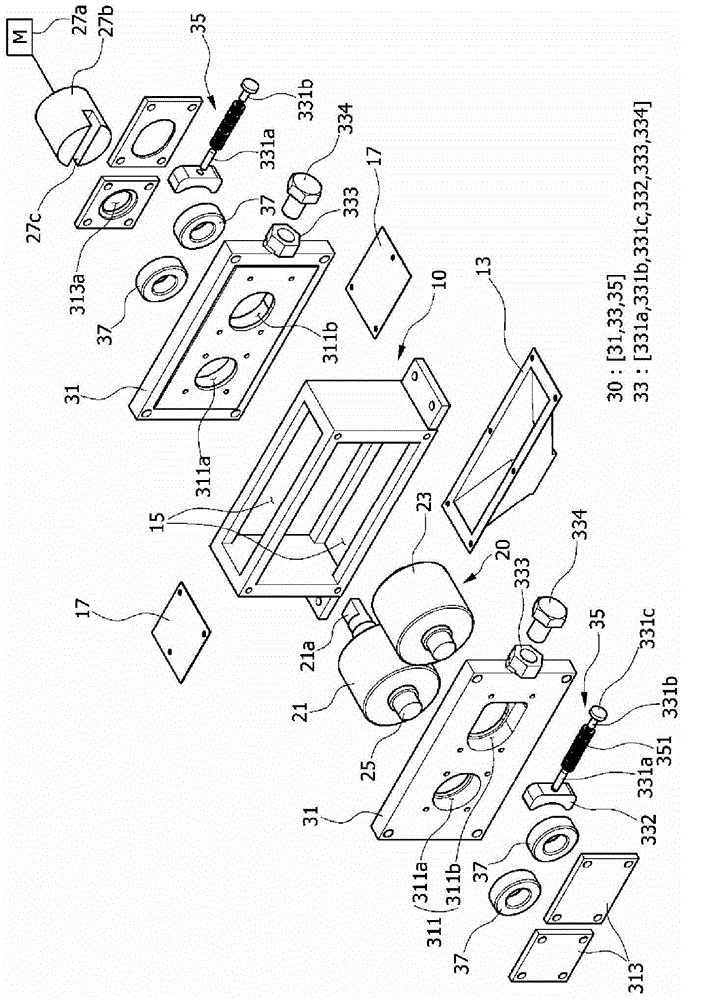

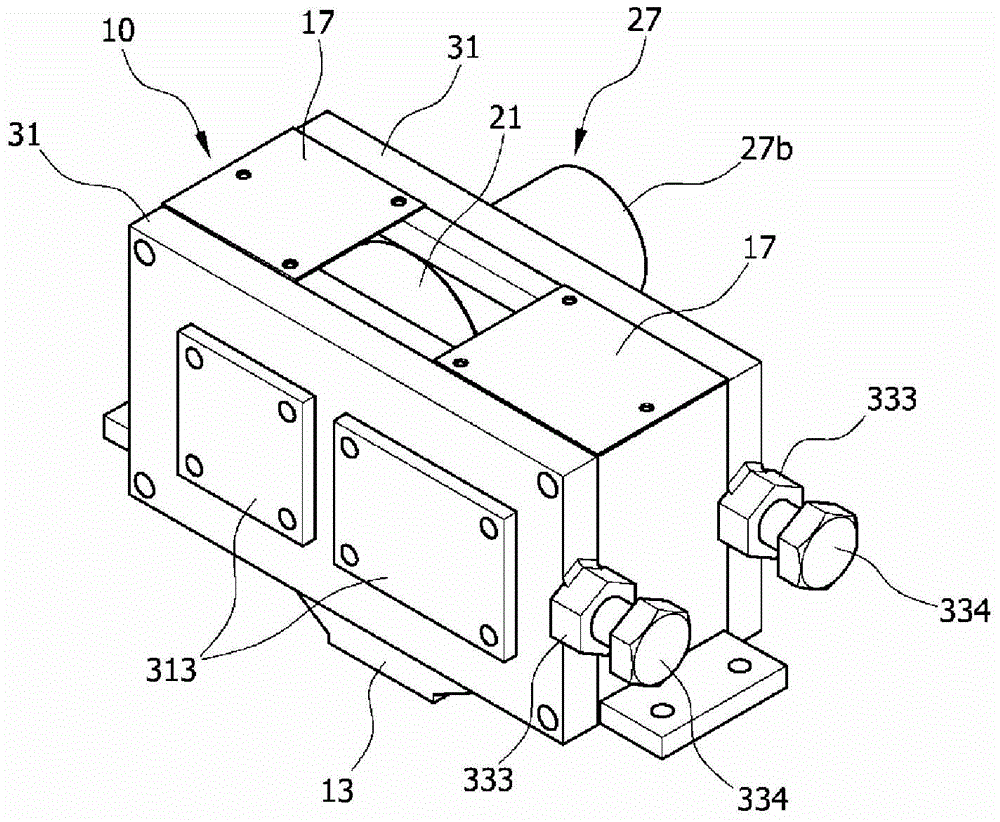

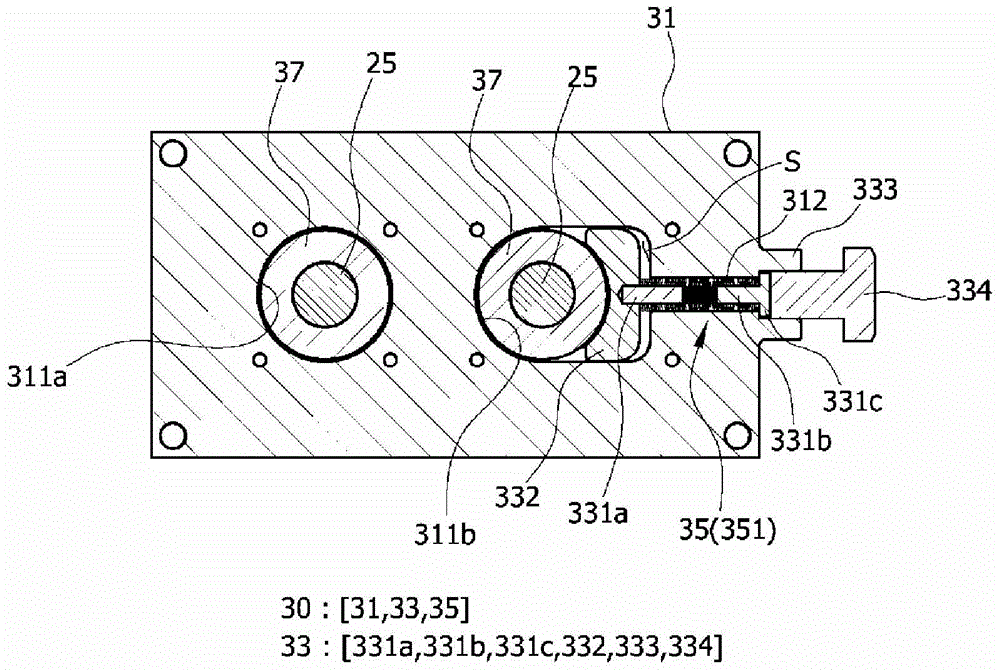

[0052] Next, the micro-roller according to the present invention will be described in more detail with reference to the accompanying drawings.

[0053] Such as Figure 1 to Figure 3 As shown, the micro-roller according to the present invention includes: a housing 10 ; a forming roll module 20 for pressurizing the loaded powder; and a rolling device 30 for pressing the cylinder of the forming roll module 20 .

[0054] Such as Figure 1 to Figure 3 As shown, the outer cover 10 according to the present invention is provided with split parts 15 on the upper, lower, front and rear sides, and the two sides of the upper split part 15 are connected with cover plates 17 in a spaced manner.

[0055] Such as Figure 4 As shown, the space between the cover plates 17 is connected to the input port 11, that is, the hopper, and the powder P or powder (hereinafter referred to as "powder") of the used nuclear fuel or radioactive waste is loaded into the inside of the outer cover 10. Forming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com