Method for the continuous production of laminates made of fibre bands and use thereof

A fiber tape and laminate technology, applied in chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve the problems of expensive manufacturing of fiber composite materials, high fiber material consumption, fiber waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

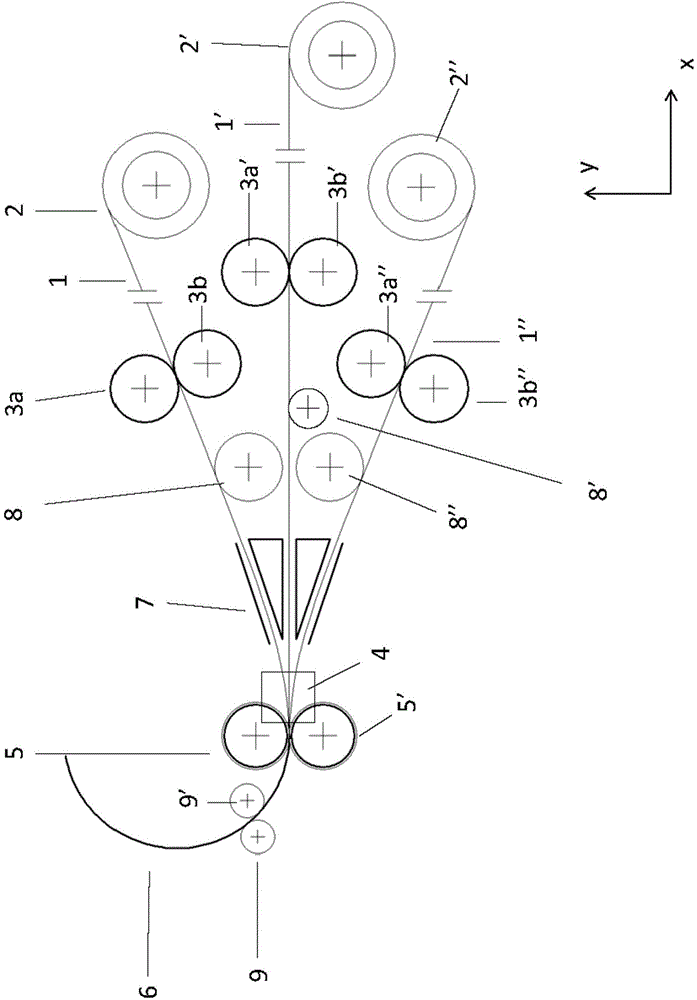

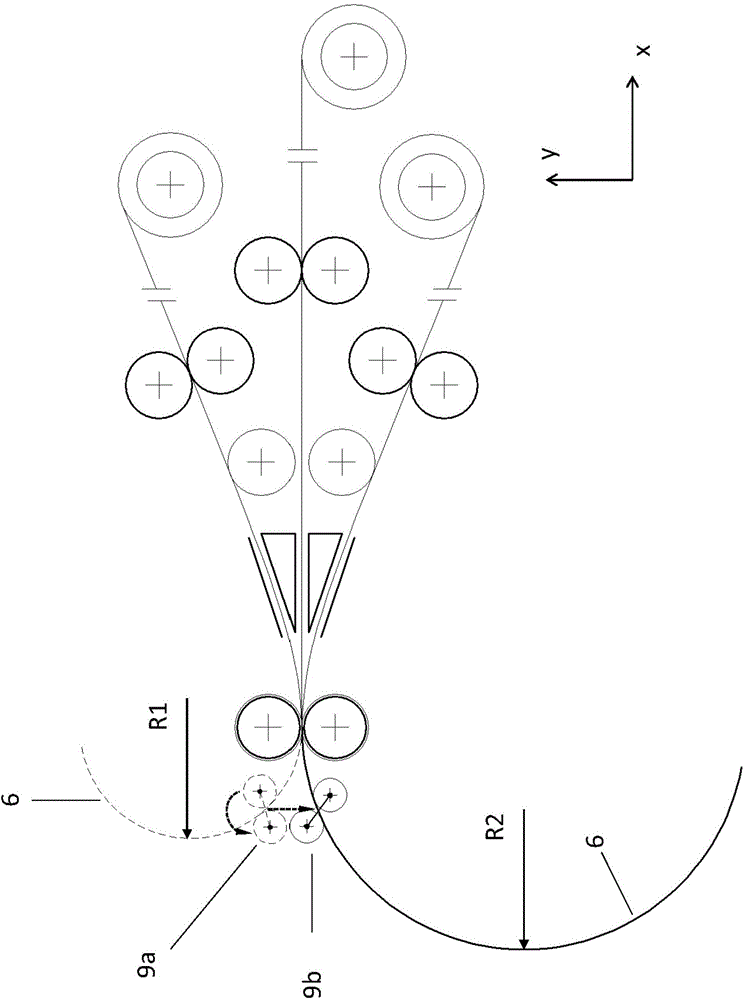

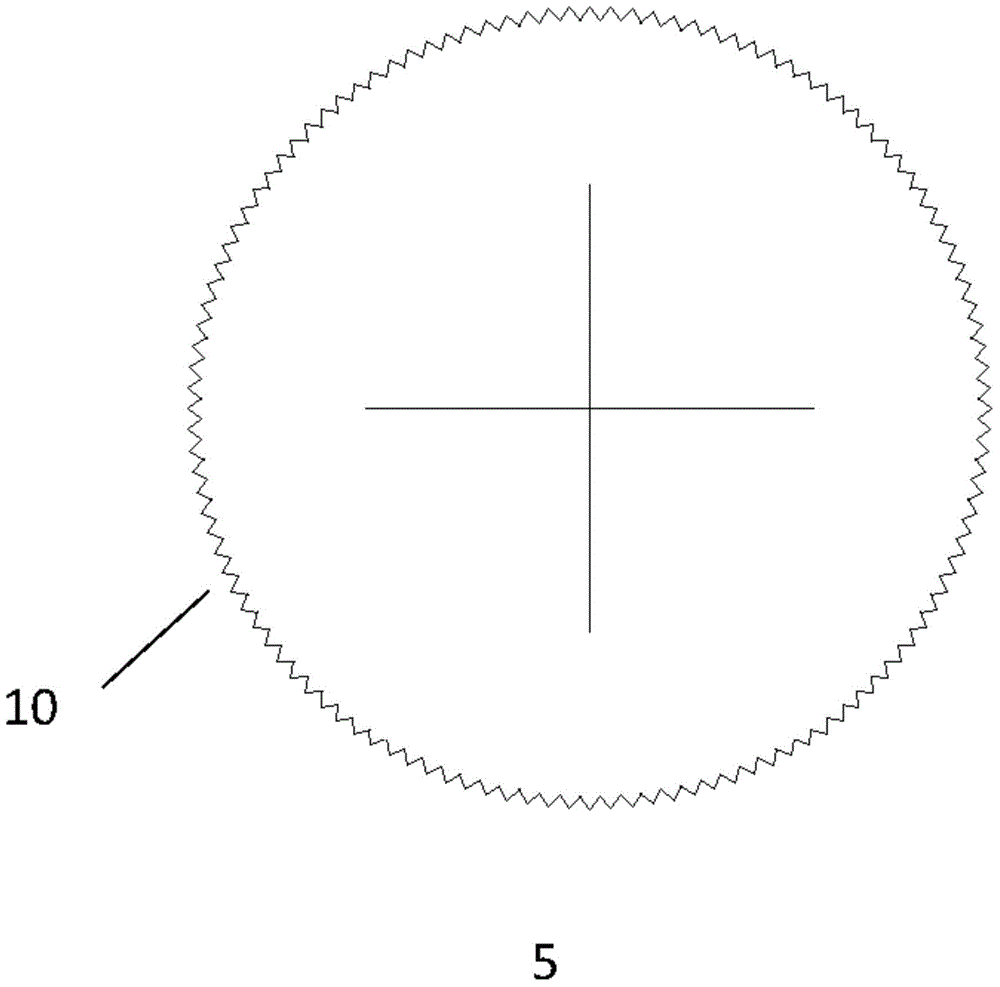

[0069] In principle, the method according to the invention can be based on figure 1 The diagram in the implementation. The fiber belt (1, 1', 1") is guided from the material storage place (2, 2', 2") to the pre-determined place via a pair of conveying rollers (3a, 3b; 3a', 3b'; 3c, 3c'). The processing station (7), optionally, can use guide rollers (8, 8', 8") to assist the conveying of the fiber belt (1, 1', 1"). In the pretreatment station (7), the fiber tape (1, 1', 1") is optionally prepared for the step of joining, for example, in the case of a fiber tape with a thermoplastic matrix, by heating and making the thermoplastic matrix at least partially The preparation is carried out by melting. Further, the fiber belt (1, 1', 1") is continuously conveyed from the pretreatment station (7) to the connection station (4). In the connecting station (4), the fiber belts (1, 1', 1") are connected by consolidation rollers (5, 5') to form a laminate (6). In the fiber belts (1, 1', 1")...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com