Multi-sealing side-hung top-suspended center-rotated overturning energy-saving window sectional material

A window profile and profile technology, which is applied in the field of multi-sealed casement top-hung, mid-rotation, flip-over energy-saving window profiles, can solve problems such as inability to achieve sealing and heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

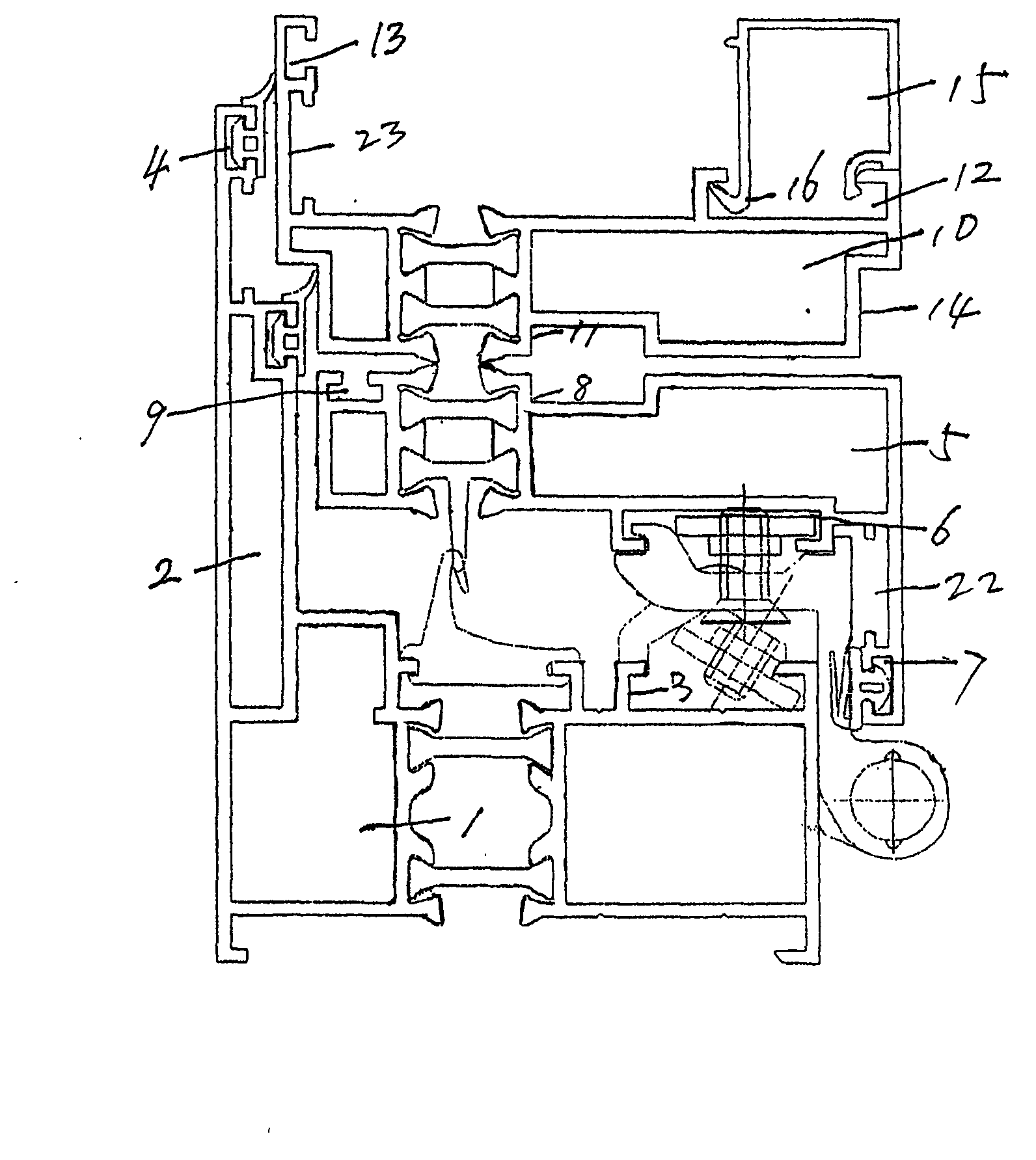

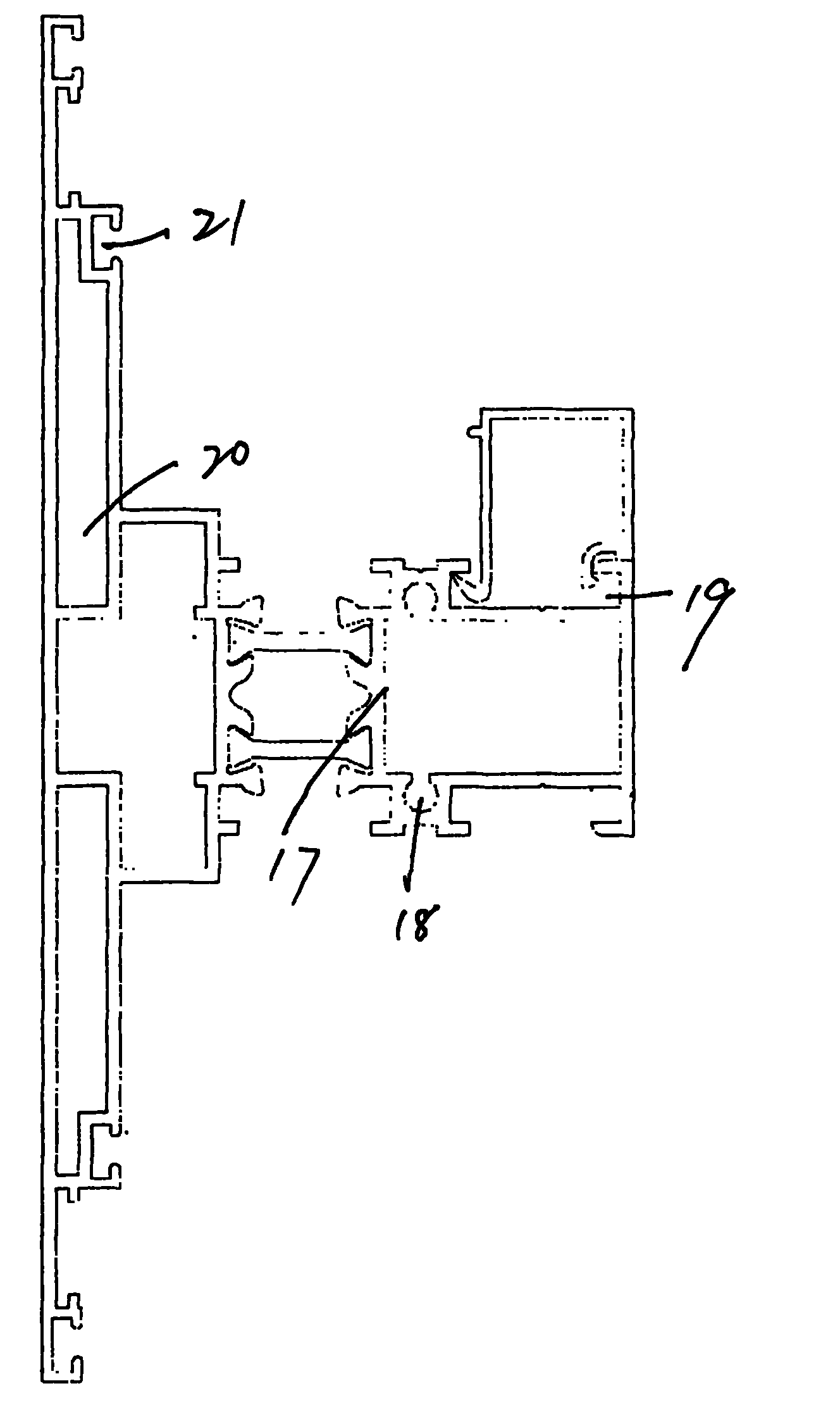

[0008] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0009] This multi-sealed casement top-hung center-rotating energy-saving window profile is composed of five parts: outer frame profile, middle stile profile, middle frame profile, center-rotation flip fan profile, and bead profile. Among them, the outer frame profile is composed of load-bearing base 1, outer facade 2, hardware installation groove 3, and sealing strip groove 4; the middle stile profile is composed of main structure 17, outer facade 20, bead groove 19, outer frame link screw groove 18, The sealing strip groove 21 is composed of; the middle frame profile is composed of the main structure 5, the inner facade 22, the hardware installation groove 6, the sealing strip groove 7, the middle rotation shaft installation groove 8, and the top sealing groove 9; the middle rotation flip fan is composed of the main structure 10. The side elevation 23, the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com