Synchronizers for manual transmissions and manual transmissions

A manual transmission and synchronizer technology, which is applied to mechanical drive clutches, clutches, transmission parts, etc., can solve the problems of difficult to control the deformation of the ring spring, stalling in back gear, incomplete pre-synchronization, etc., to achieve good synchronization function, improve Shift lever ratio and excellent shift feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

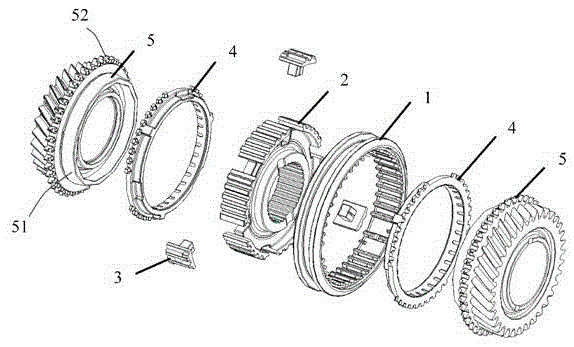

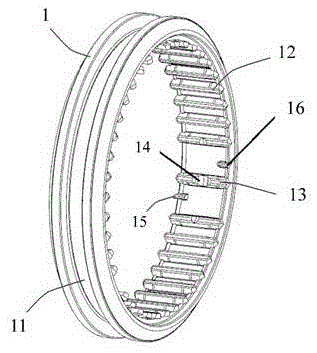

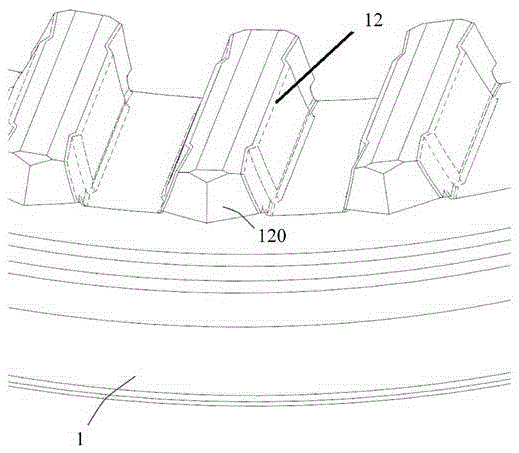

[0031] The specific embodiments of the present invention will be described in detail below with reference to the drawings.

[0032] It is easy to understand that according to the technical solution of the present invention, without changing the essential spirit of the present invention, a person of ordinary skill in the art can propose various alternative structural modes and implementation modes. Therefore, the following specific embodiments and drawings are only exemplary descriptions of the technical solutions of the present invention, and should not be regarded as all of the present invention or as a limitation or limitation to the technical solutions of the present invention.

[0033] The directional terms such as up, down, left, right, front, back, front, back, top, and bottom that appear or may appear in this specification are defined relative to the structure shown in the drawings, and they are relative The concept, therefore, may change accordingly according to different l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com