Coiler Front Side Guide System for Hot Rolling Line

A technology for the front side of the machine and the guide plate is applied in the field of auxiliary devices of the hot rolling line coiler. Service life, the effect of preventing edge strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following non-limiting examples illustrate the invention.

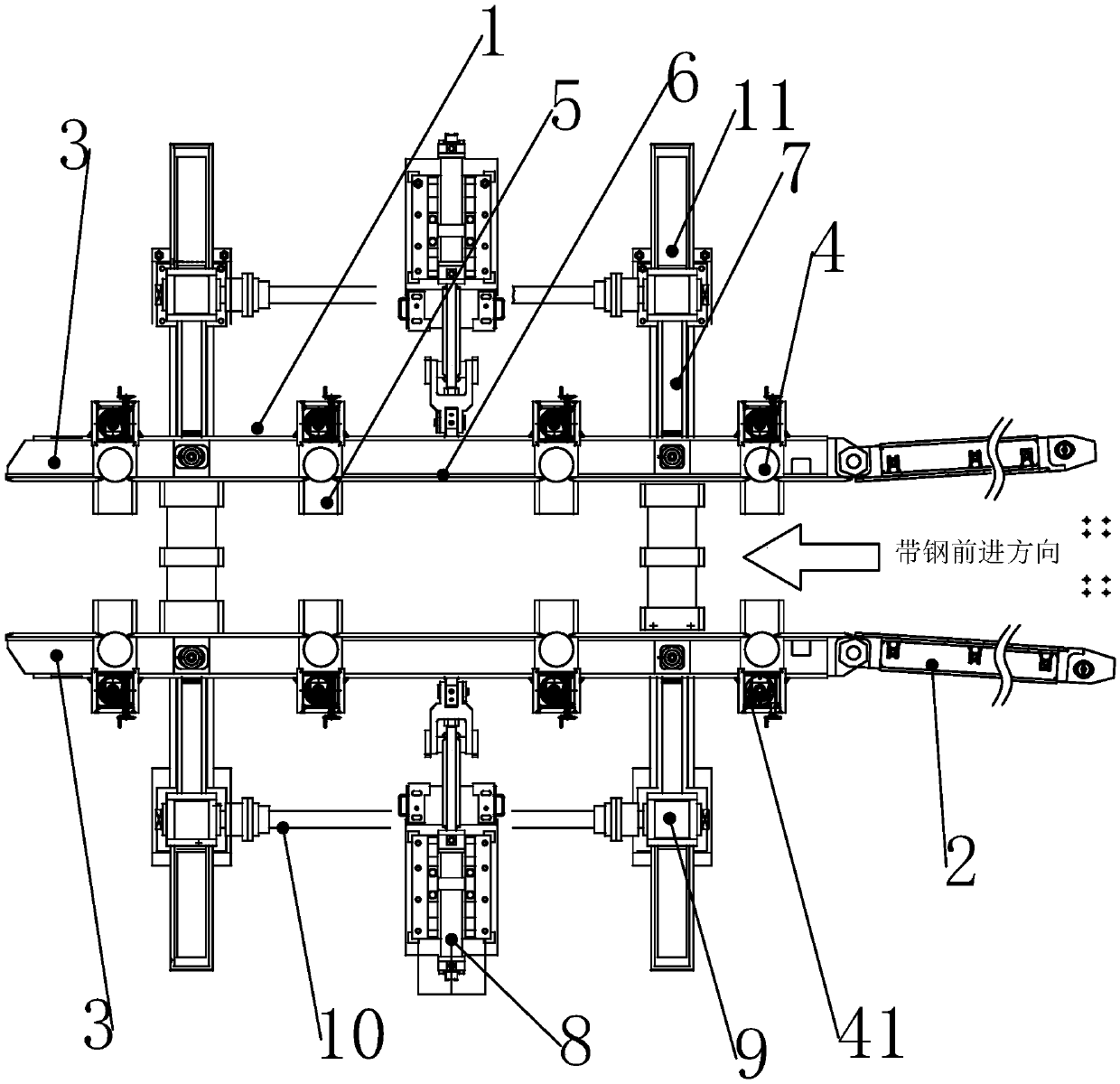

[0029] Such as figure 1 As shown, a front side guide plate system of a hot rolling coiler includes a hinged parallel section guide plate 1 and an inclined section guide plate 2, and both of them are composed of a symmetrical arrangement of the operation side and the transmission side (the upper and lower sides are symmetrical as shown in the figure) Two sides), there is a conveying roller between the operation side and the transmission side, the parallel section guide plate 1 operation side and the transmission side both include a guide plate 3, and several vertical rollers 4 arranged on the guide plate 3 along the extending direction of the guide plate 3, on the guide plate 3 A number of transition guide plates 5 arranged on the inner side along the extending direction of the guide plate 3, a lining plate 6 arranged on the inner side of the guide plate 3 along the extending direction of the guide plate 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com