Drain-off device for preventing generation of steam locking favorably

A steam lock and water-repellent technology, applied in the direction of steam traps, mechanical equipment, etc., can solve the problems of unfavorable heat transfer efficiency of heat exchange equipment, safety and reliability of steam pipe network, easy occurrence of steam lock, etc., to achieve simple structure, prevent steam leakage The effect of venting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

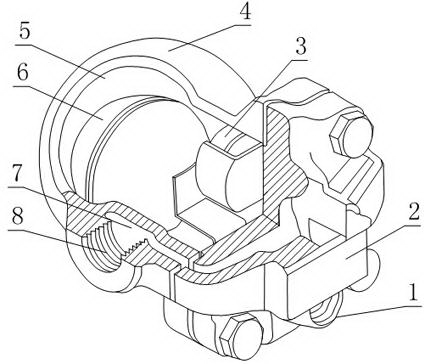

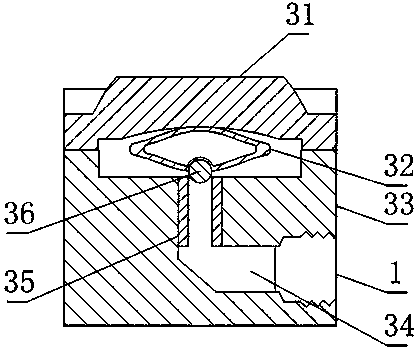

[0022] Such as figure 1 and figure 2 , a kind of drainage device that is beneficial to prevent vapor lock provided by the present invention includes a left valve cover 4 and a right valve cover 2 connected by bolts, a condensed water volume chamber 5 is arranged between the left valve cover 4 and the right valve cover 2, The left valve cover 4 or the right valve cover 2 is provided with an inlet pipe 8 and an outlet pipe 1 connected with the condensed water volume chamber 5, and the condensed water volume chamber 5 is provided with a floating ball 6, and also includes a 5 on the upper side of the evacuation device 4, the evacuation device 4 includes a thermostatic metal sheet 32, a sealing ball 36, and a steam lock discharge flow channel 34 arranged on the left valve cover 4 or the right valve cover 2, the The front and rear ends of the steam lock discharge channel 34 are respectively connected with the condensed water volume chamber 5 and the outlet pipe 1, and the sealing ...

Embodiment 2

[0025] This embodiment is further limited on the basis of embodiment 1: as figure 1 and figure 2 , in order to reduce the possibility that the present invention is blocked by impurities such as rust and welding slag in the pipe network, and prolong the service life of the sealing surface in the present invention, a filter screen groove 7 is also included, and the filter screen groove 7 is arranged on the inlet pipe 8 At any position from the inlet end to the flow path of the condensed water volume chamber 5, the filter screen groove 7 is used for setting the filter screen.

[0026] A seal seat 35 is embedded in the inlet section of the steam lock discharge channel 34, and the material of the seal seat 35 is stainless steel. The provided sealing seat 35 is used to increase the wear resistance of the sealing surface formed by the sealing ball 36 and the steam lock discharge channel 34, which is beneficial to the service life of the present invention.

Embodiment 3

[0028] The present embodiment is further limited on the basis of embodiment 1: as figure 1 and figure 2 , the emptying device 4 also includes an upper cover 31 and a lower cover 33 that are detachably connected, and a sheet metal accommodation cavity is formed between the upper cover 31 and the lower cover 33, and the thermostatic metal sheet 32 is located on the metal sheet. The metal sheet accommodating chamber communicates with the condensed water volume chamber 5 through the labyrinth channel. The set labyrinth flow channel avoids the steam or non-condensable gas entering the present invention from directly colliding with the thermostatic metal sheet 32 through the setting of the flow channel corner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com