Ejection additional load simulation test system

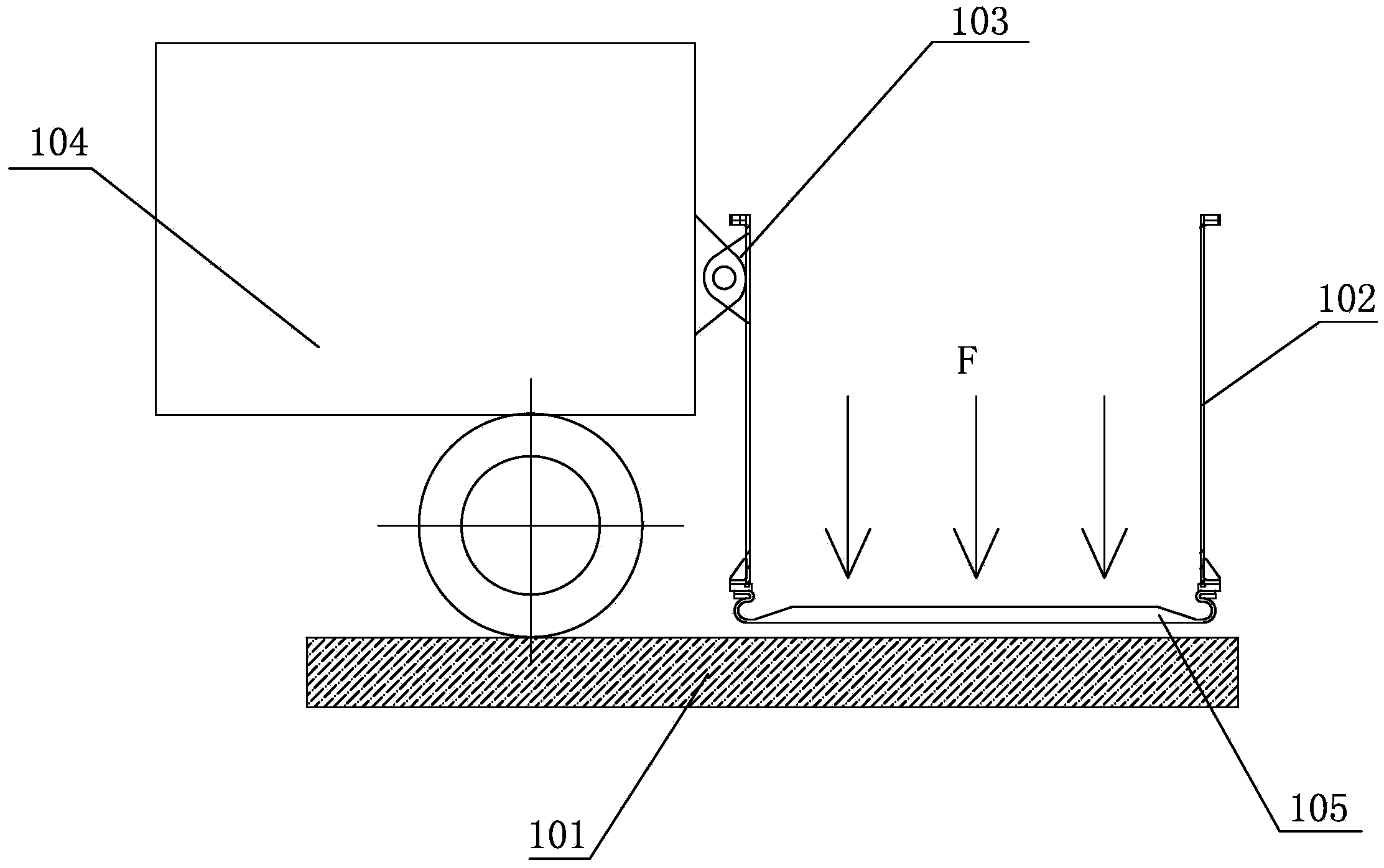

A technology for simulating test system and additional load, applied in the field of weapons, can solve problems such as structural optimization of launchers, and achieve the effects of structural optimization, load reduction, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

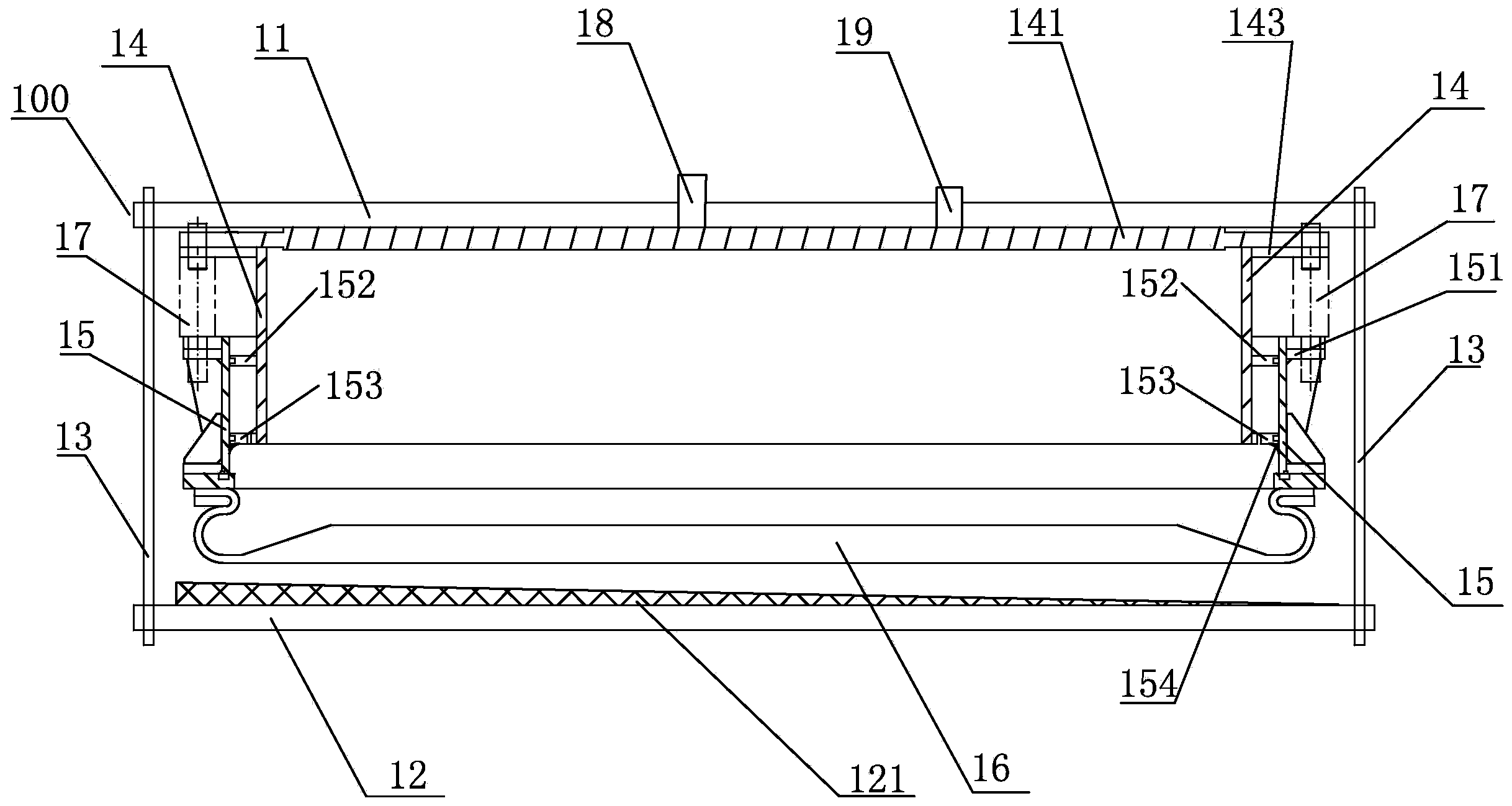

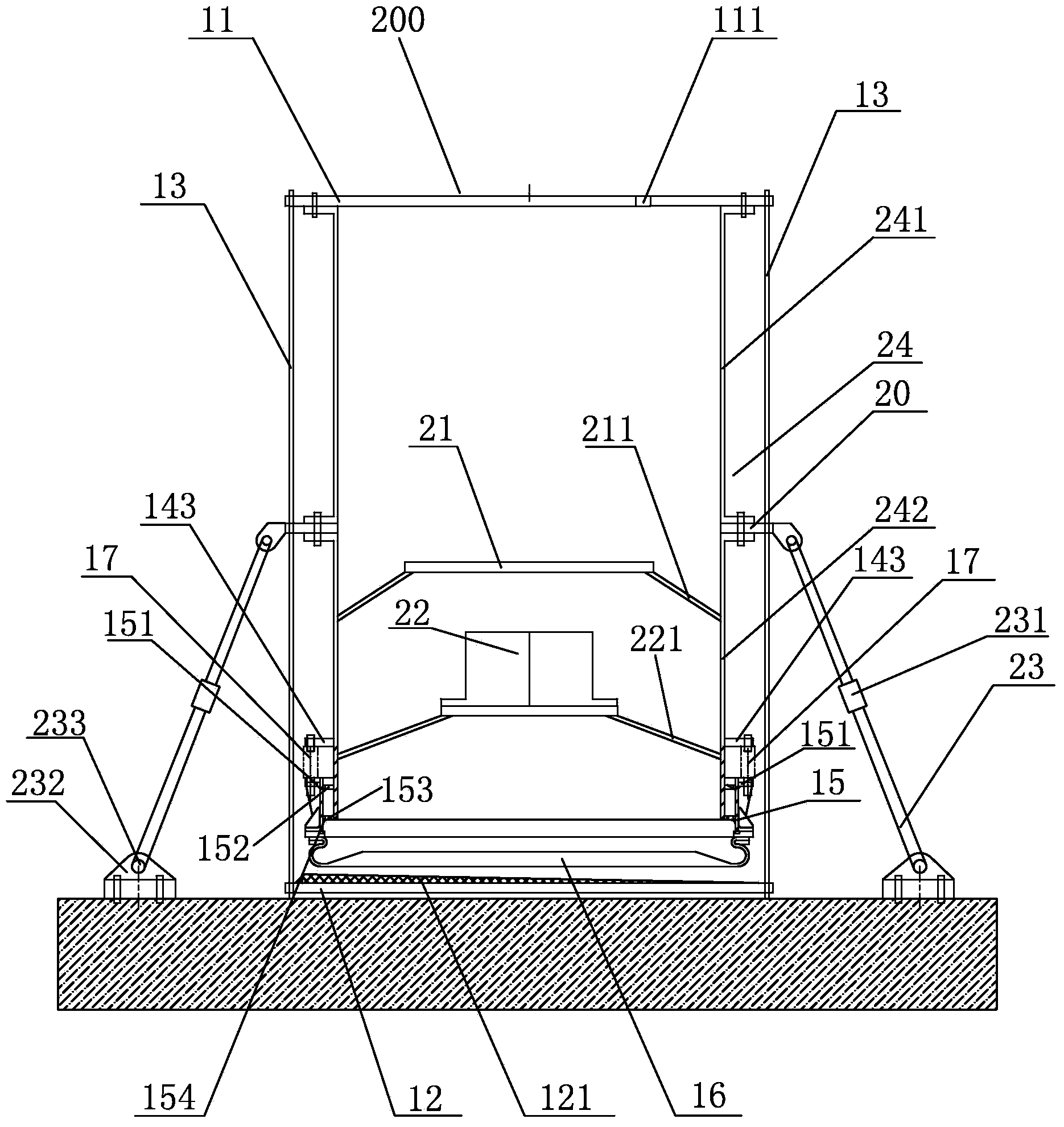

[0021] like figure 2 Shown is the first embodiment of the present invention, a static simulation test system for ejection additional load, including an outer frame 100 composed of a horizontally arranged upper cover plate 11, a lower cover plate 12, and vertically arranged straight pull rods 13. The shape of the cover plate 11 and the lower cover plate 12 is generally circular, of course, it can also be designed as a square according to actual needs. The positions of the upper cover plate 11 and the lower cover plate 12 are symmetrical up and down, and the outer peripheries of the upper cover plate 11 and the lower cover plate 12 are fixedly connected with several straight pull rods 13. Preferably, the upper cover plate 11 and the lower cover plate 12 are provided with Several screw holes, the upper and lower ends of the straight pull rod 13 respectively penetrate the screw holes on the upper cover plate 11 and the lower cover plate 12, and then fix them with bolts, so that w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com