Three-directional load experiment system for airport pavement

An airport runway and load test technology, which is applied in the direction of testing material strength by applying repetitive force/pulsation force, and testing material strength by applying stable tension/pressure, which can solve the problem of uncontrollable, fixed-point testing and not airport pavement , applying lateral shear force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

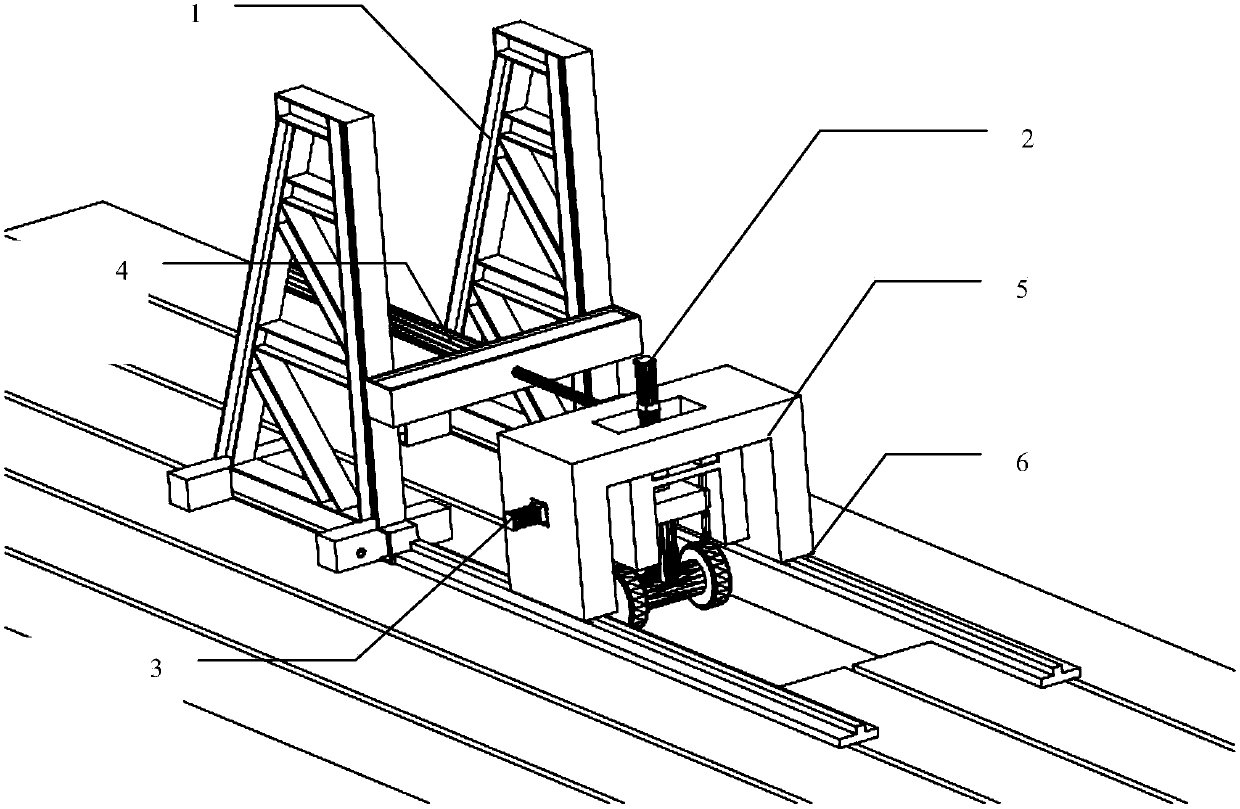

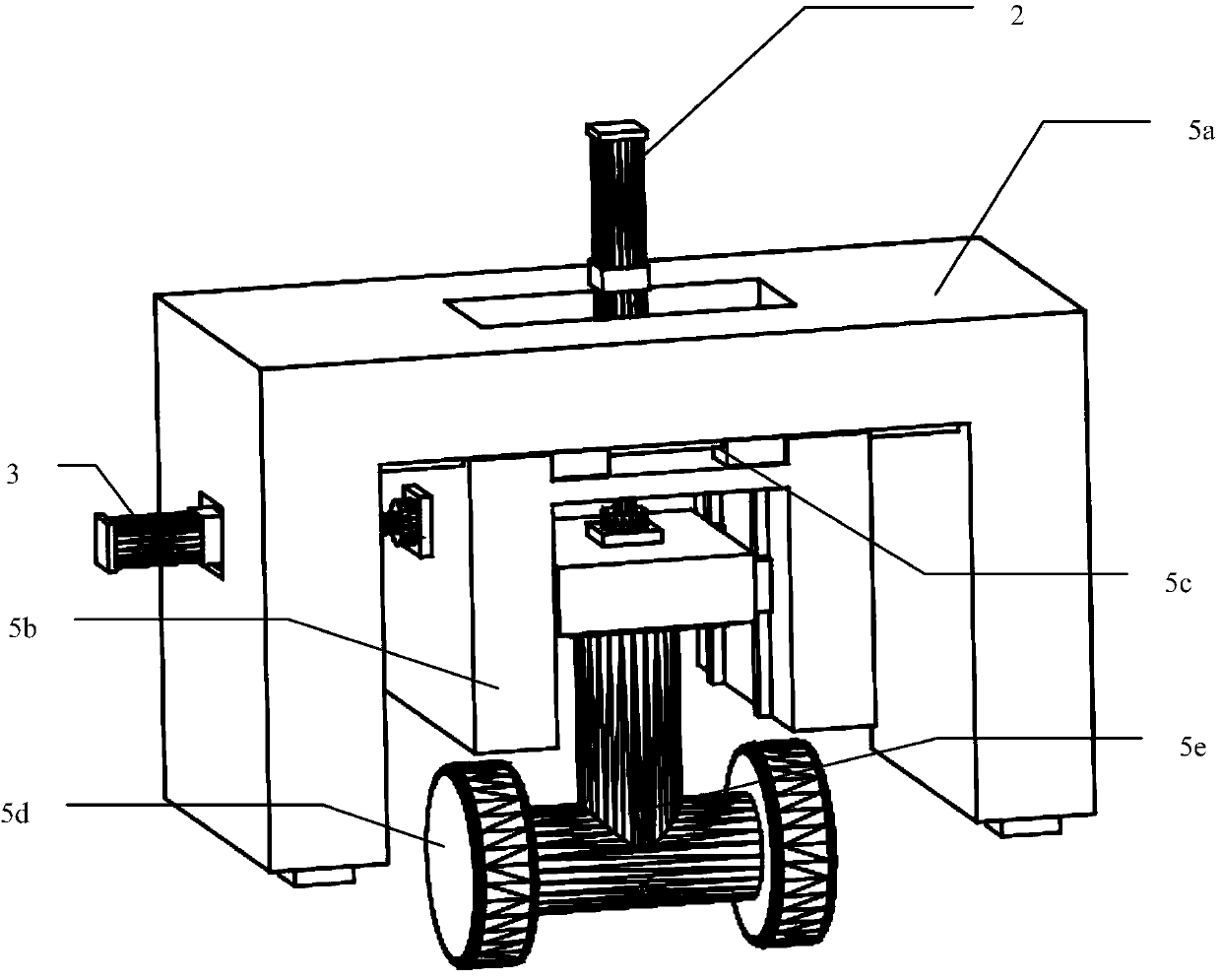

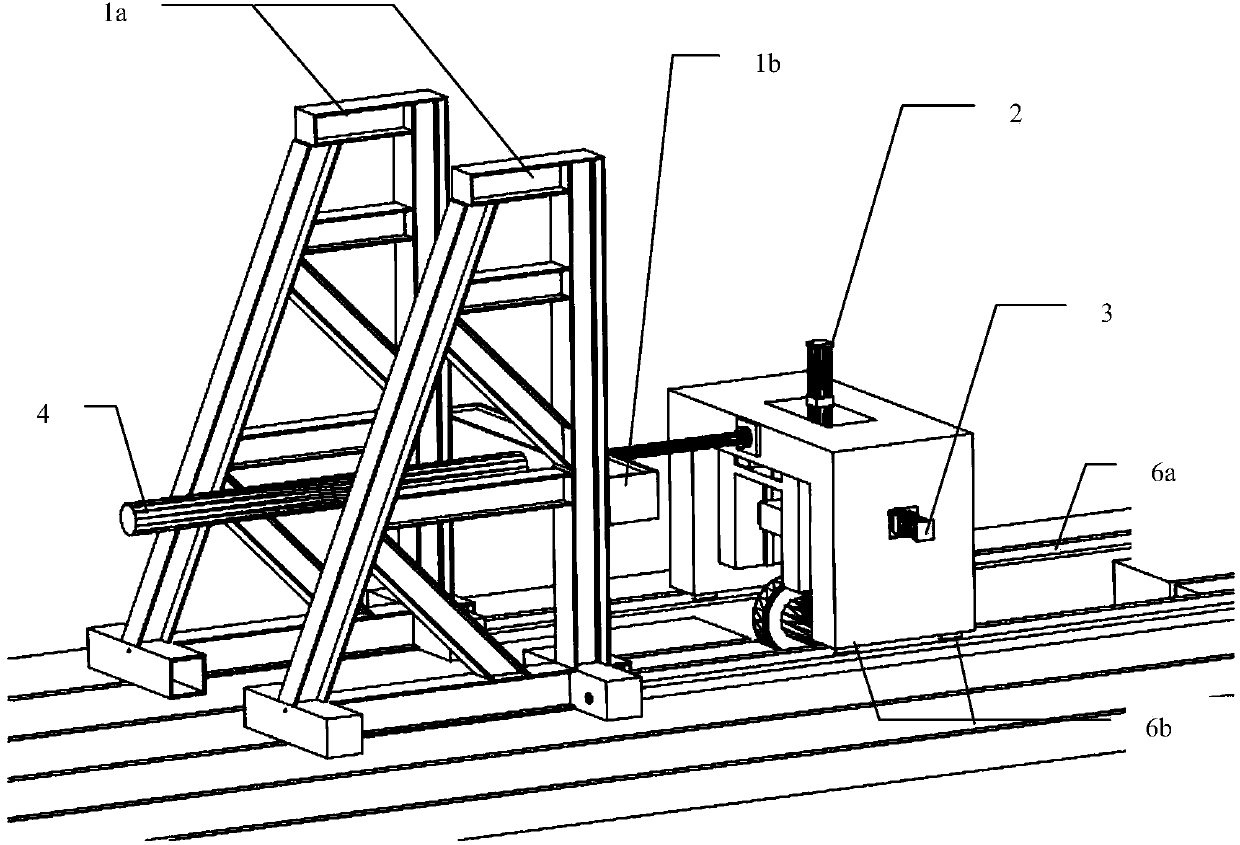

[0028] See figure 1 — image 3, the present invention is a three-way load test system for an airport runway, which includes three sets of electro-hydraulic servo actuators 2, 3, 4, a horizontal bearing frame 1, a low-friction motion mechanism 6 and a double-wheel test device 5, etc. The position connection relationship between them is: take the runway as the center, the long side of the runway is the north-south direction, and the short side is the east-west direction. The surface of the runway is directly affected by two solid tires 5d, and the position of the solid tires 5d is fixed by the axle 5e at the lower end of the internal loading frame device 5b in the double-wheel test device 5. The top of the internal loading frame equipment 5b is connected to the external frame 5a through the equipment guide rail 5c, and the equipment guide rail 5c is along the east-west direction, which can ensure that the internal loading frame equipment 5b runs along the east-west direction. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com