Chemical product production mode optimization method, device and continuous chemical system

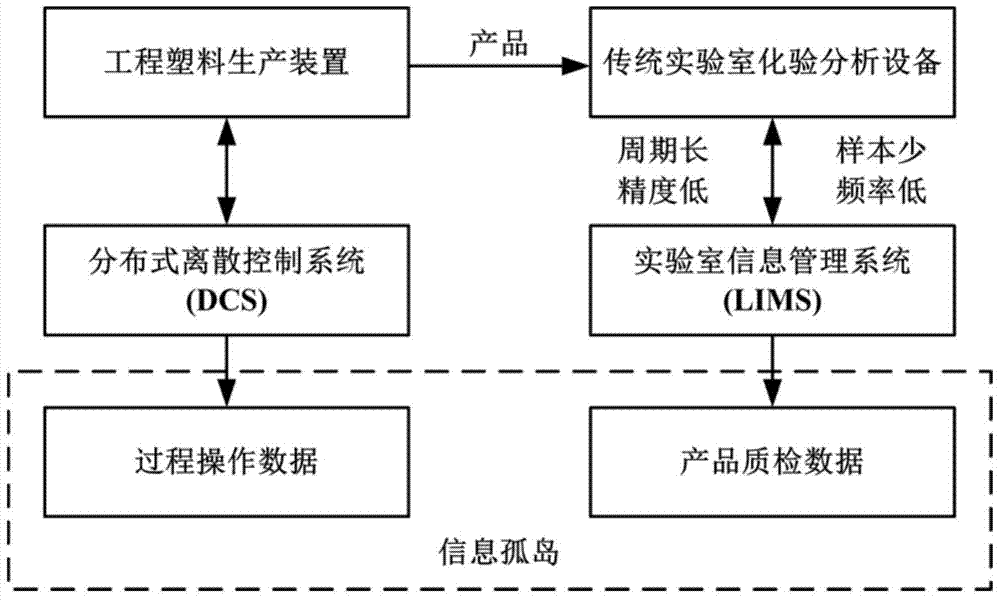

A production mode and technology of chemical products, applied in the chemical industry, can solve problems such as low efficiency, few samples collected, and lagging analysis results, and achieve the effect of quickly identifying and optimizing the production mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

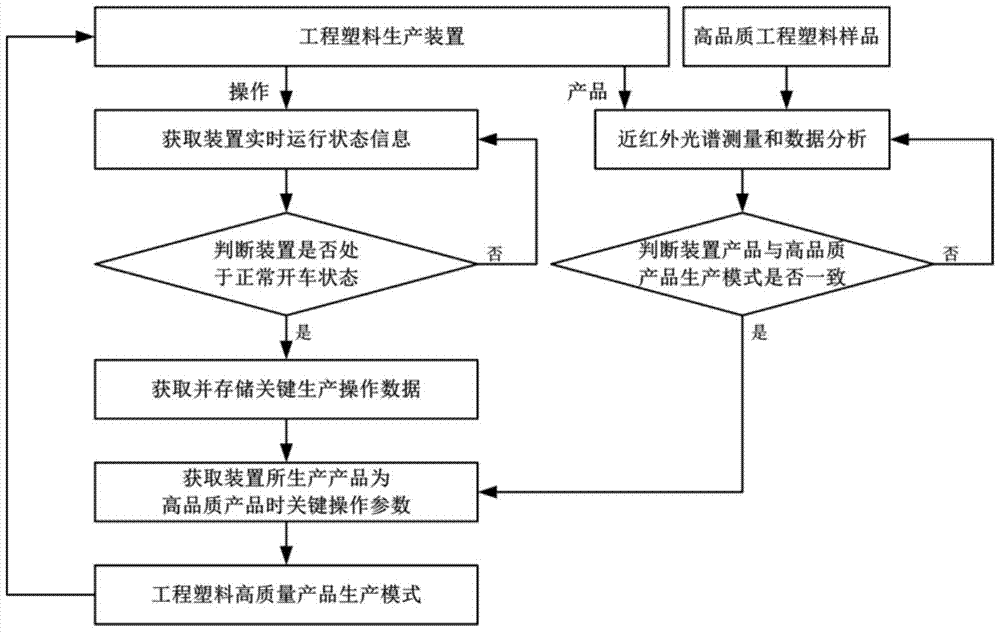

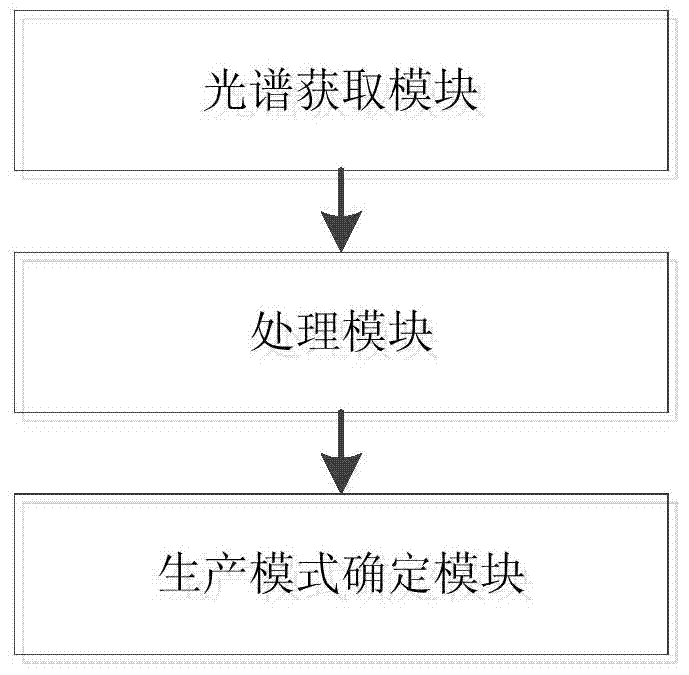

Method used

Image

Examples

Embodiment Construction

[0018] Near-infrared spectroscopy (NIR) analysis technology is a rapidly developing high-tech analysis technology in the field of analytical chemistry. Its working principle is that if the composition of the sample is the same, the spectrum is the same, and vice versa. If we establish the corresponding relationship between the spectrum and the parameters to be measured (called an analysis model), then, as long as the spectrum of the sample is measured, the required quality parameter data can be quickly obtained through the spectrum and the above-mentioned corresponding relationship. Compared with traditional analysis technology, near-infrared spectroscopy analysis technology has many advantages. It can complete the measurement of multiple performance indicators (at most Up to ten indicators). There is no need to pre-treat the analysis sample during the spectrum measurement; no other materials are consumed or the sample is destroyed during the analysis; the analysis has good rep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com