Excessively-low-current protection lightning-stroke-resisting surge wire-wound resistor

A current protection and anti-lightning strike technology, which is applied in the direction of resistor shell/packaging shell/potting, spiral coil/screw disk resistance elements, etc., can solve the problems of potential safety hazards, burning of plastic parts, continuous heating of resistors, etc., to prevent safety Hidden dangers, the effect of speeding up the fusing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing:

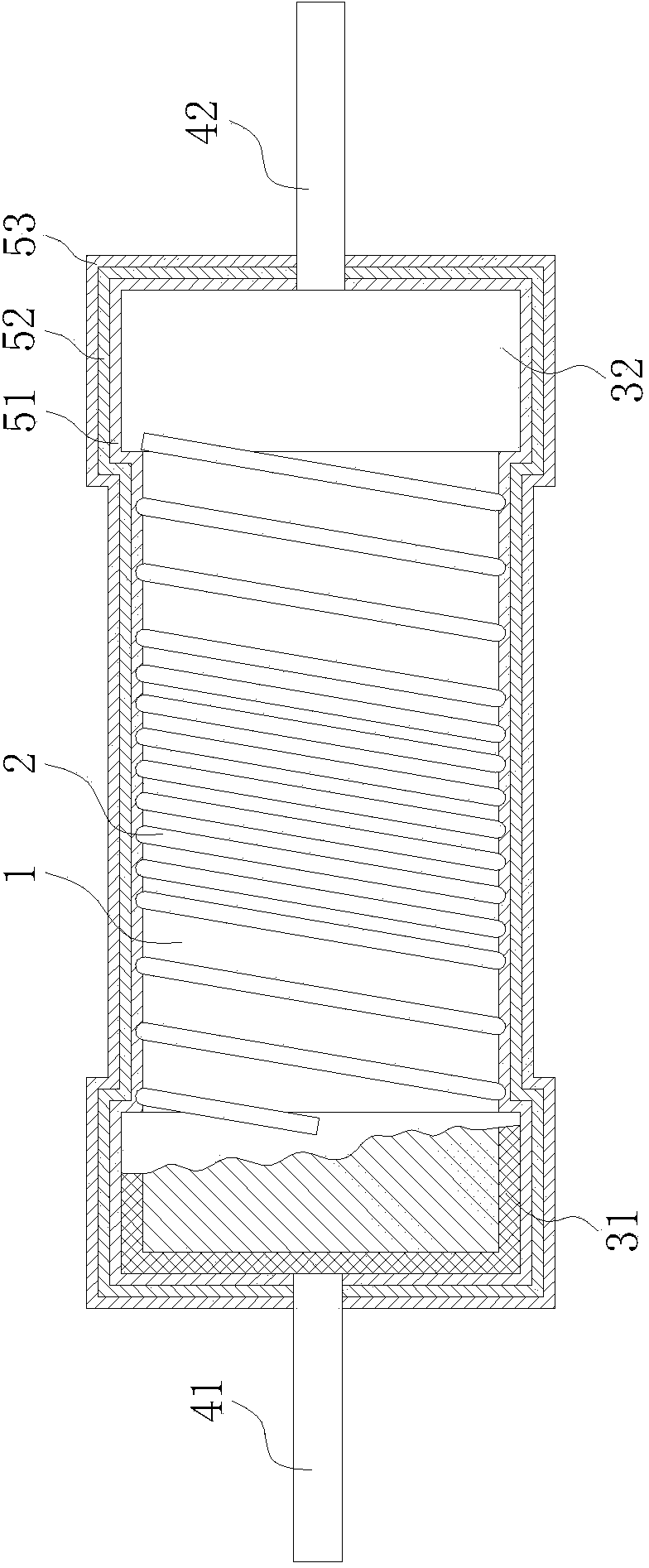

[0010] see figure 1 .

[0011] Over-low current protection anti-lightning surge wire wound resistor, which includes a mandrel 1, a resistance wire 2 is wound on the mandrel 1, a cap 31, 32 is set at both ends of the mandrel 1, and one end of the resistance wire 2 is connected to the The cap 31 is connected, the other end of the resistance wire 2 is connected to the cap 32, a section of wire 41 is connected to the cap 31, a section of wire 42 is connected to the cap 32, and the winding density of the resistance wire 2 in the middle of the mandrel 1 is greater than that close to The winding density at the two ends, the outside of the cap 31, the cap 32, the mandrel 1 and the resistance wire 2 on it is wrapped with a flame-retardant layer, and the flame-retardant layer includes the inner flux layer 51, the middle The barrier temperature suppression layer 52 and the insulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com