Stable and efficient novel combustion agent and preparation method thereof

A kind of incendiary, high-efficiency technology, applied in offensive equipment, non-explosive/non-thermal agent components, explosives, etc., can solve the problems that are not conducive to the application of incendiary agents, the combustion temperature of the incendiary agent is not high enough, and achieve excellent stability and reduce sensitivity indicators. , the effect of high flame temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

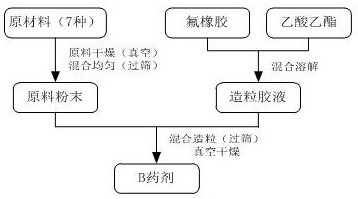

[0024] In addition, the present invention also provides a method for preparing a new type of stable and efficient combustion agent, comprising the following steps: Step (1): mixing raw material powders, mixing high-energy aluminum alloy powder or magnesium aluminum alloy powder, ferrous oxide, molybdenum trioxide , copper oxide, tungsten powder, and dispersant, mix evenly in proportion, vacuum-packed, and set aside; step (2): preparation of granulated glue, crushed fluororubber, weighed and added to a certain mass of ethyl acetate , stirring regularly to make it completely dissolved for about 7 days to 10 days; step (3): mixing and granulating, mixing the raw material powder and the granulation glue in proportion, and adding ventilation and full stirring; Coarse granules, sieve with a 40-mesh sieve, stir evenly after sieving, repeat the sieving once, stir evenly, put the sieved pharmaceutical powder in a drying room at 40 ° C ~ 50 ° C, dry for 4 hours, The resulting mixture is...

Embodiment 1

[0037] see Figure 1-Figure 3 , This embodiment provides a new type of stable and efficient combustion agent, which includes the following components in parts by weight: 18 parts of high-energy aluminum alloy powder or magnesium aluminum alloy powder, 12 parts of ferric oxide, 3 parts of molybdenum 50 parts of copper, 0.5 parts of tungsten powder, 1 part of dispersant, and 2 parts of fluororubber.

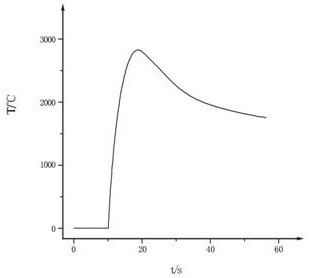

[0038]The new type of burning agent prepared in Example 1, according to GJB5384.8-2005 "Pyrotechnic Powder Performance Test Method Part 8: Flame Temperature Determination Thermal Radiation Method", test conditions: ambient temperature: 15 ~ 35 ℃; relative humidity is less than or It is equal to 80%; the wind speed at the center of the flame in the combustion tower is 1~1.5m / s, and the test is carried out.

[0039] The experimental effect of burning steel plate is as follows figure 2 shown. The combustion temperature curve of Example 1 is as follows image 3 shown. During the ...

Embodiment 2

[0042] see Figure 4 , this embodiment provides a new type of stable and efficient combustion agent, which includes the following components in parts by weight: 21 parts of high-energy aluminum alloy powder or magnesium aluminum alloy powder, 15 parts of ferric oxide, 5 parts of molybdenum 55 parts of copper, 2 parts of tungsten powder, 3 parts of dispersant, and 5 parts of fluororubber.

[0043] The combustion temperature curve of the novel burning agent prepared in Example 2 is as follows: Figure 4 shown. It can be seen from the test results in the figure that the combustion temperature corresponding to the new combustion agent is relatively high, up to 3065 °C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com