Semiconductor device

A semiconductor and device technology, which is applied in the field of semiconductor preparation, can solve the problems that electric fuses are difficult to completely blown, electric fuse conductive plugs are prone to damage, and electric fuse fuses have low yields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0072] The preparation process of the above-mentioned conductive plug may include:

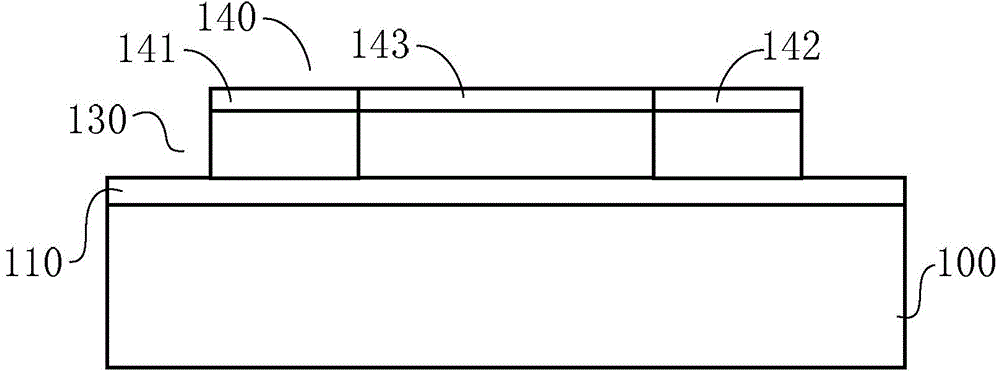

[0073] refer to Figure 10 As shown, after the conductive layer 140 is formed, a dielectric layer 160 is formed above the insulating layer 110 and the conductive layer 140, and the dielectric layer 160 can be selected from dielectric materials such as silicon oxide, silicon nitride, and silicon oxynitride. .

[0074] In this embodiment, the material of the dielectric layer 160 is silicon oxide, and its formation process is CVD (Chemical Vapor Deposition).

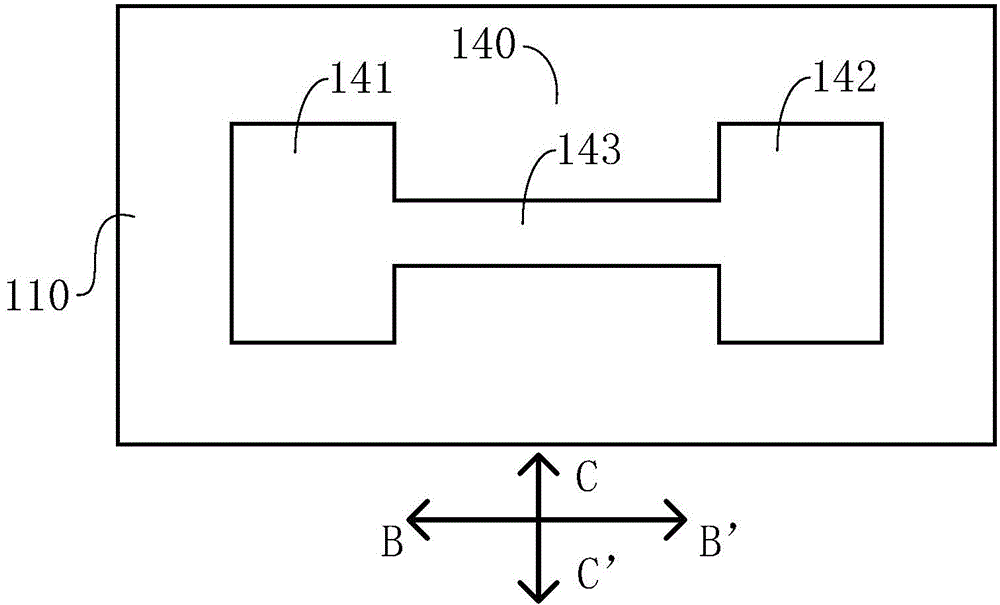

[0075] refer to Figure 11 As shown, in the dielectric layer 160, a first through hole 161 and a second through hole 162 are opened above the cathode 141 and the anode 142 of the conductive layer 140 until the cathode 141 and the anode 142 are exposed.

[0076] The specific process of opening the first through hole 161 and the second through hole 162 includes covering a hard mask layer (not shown in the figure) and a photoresist layer (n...

Embodiment

[0083] Embodiment: One above-mentioned conductive plug with a "T" structure is arranged on each of the anode and the cathode, wherein the width of the end is 160 nm, and the length is 80 nm; the width of the neck is 30 nm, and the length is 80 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com