Patents

Literature

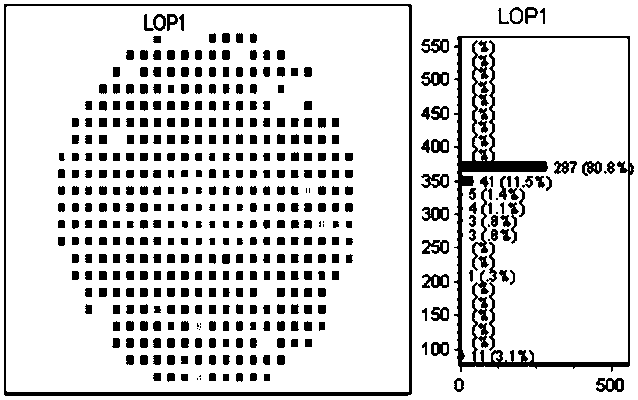

30results about How to "Improve the uniformity of current distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

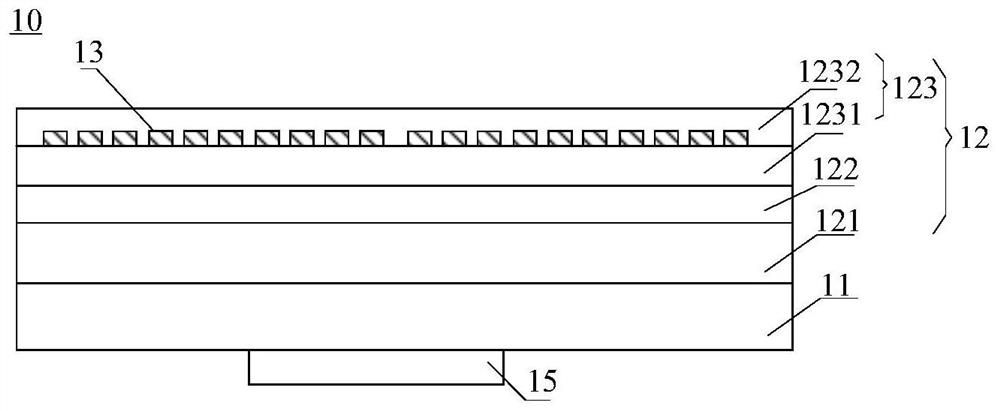

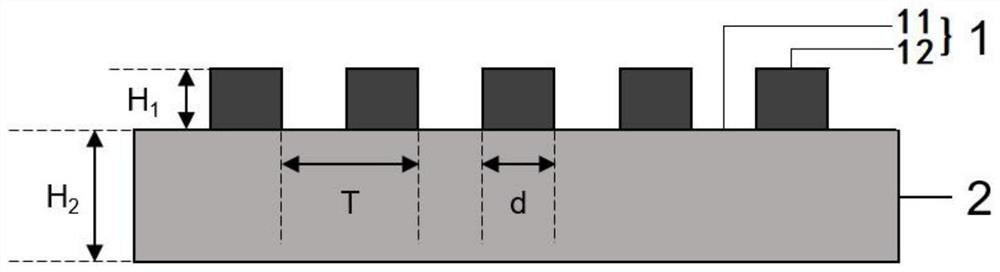

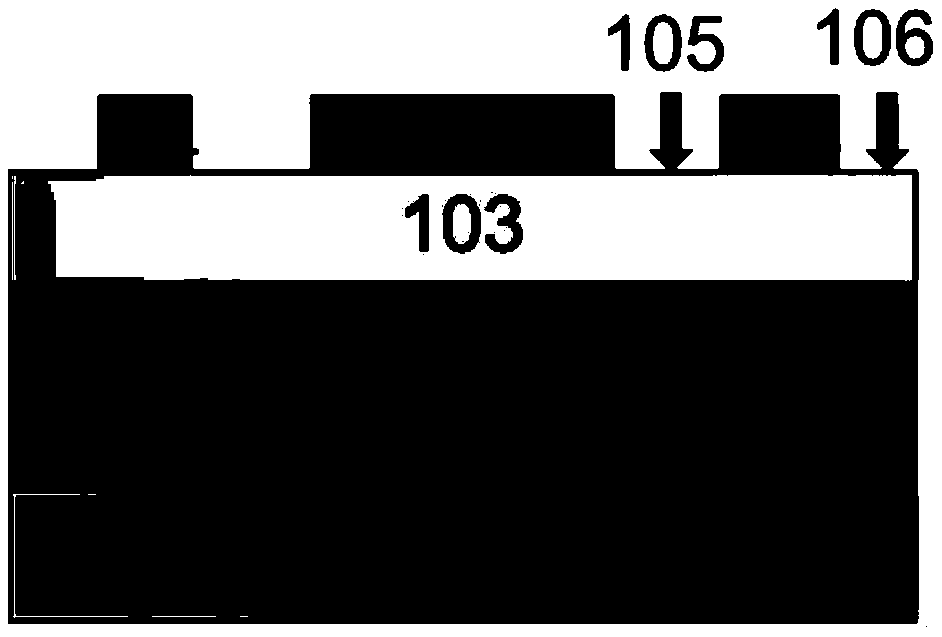

Epitaxial growth method for improving current expansion capability of nitride LED

InactiveCN111129240AImprove conductivityLower lateral resistanceSemiconductor devicesGraphiteGallium nitride

The invention provides an epitaxial growth method for improving the current expansion capability of a nitride LED, and the method comprises a process of growing a graphene layer, and specifically comprises the steps: 1, processing a substrate; 2, growing a low-temperature nitride buffer layer on the substrate and forming an irregular island on the low-temperature nitride buffer layer, wherein thelow-temperature nitride buffer layer comprises at least one of gallium nitride, aluminum nitride or aluminum gallium nitride; 3, growing a non-doped gallium nitride layer; 4, growing a silicon-doped N-type gallium nitride layer containing a graphene layer; 5, growing a light-emitting layer; 6, growing an aluminum and magnesium doped P-type aluminum gallium nitride layer containing a graphene layer; 7, growing a P-type gallium nitride layer doped with magnesium; 8, carrying out heat preservation for 20-30 minutes at the temperature of 650-680 DEG C, closing the heating system and the gas supplysystem, and carrying out furnace cooling. The epitaxial growth method provided by the invention can effectively improve the current expansion condition of the light-emitting diode.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

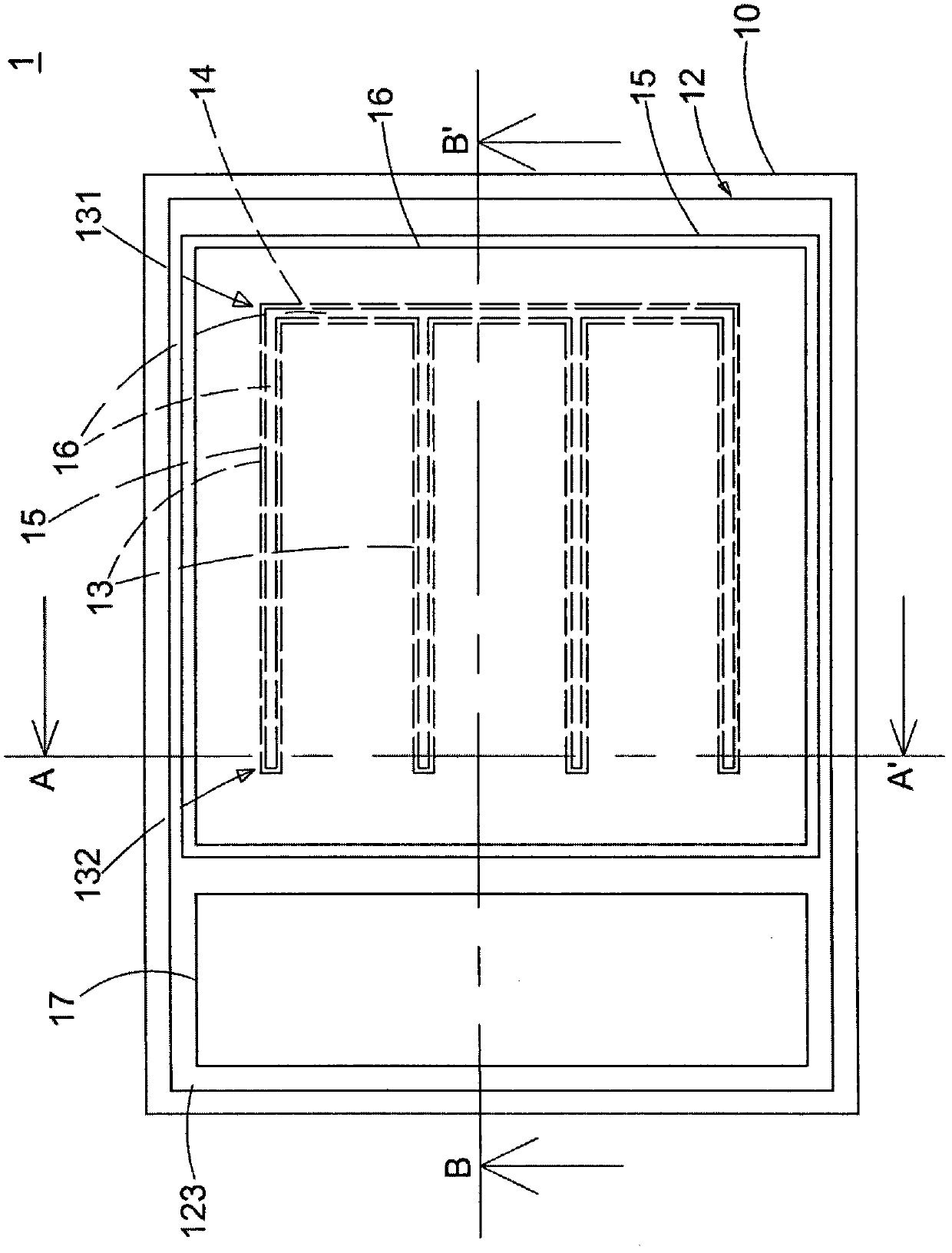

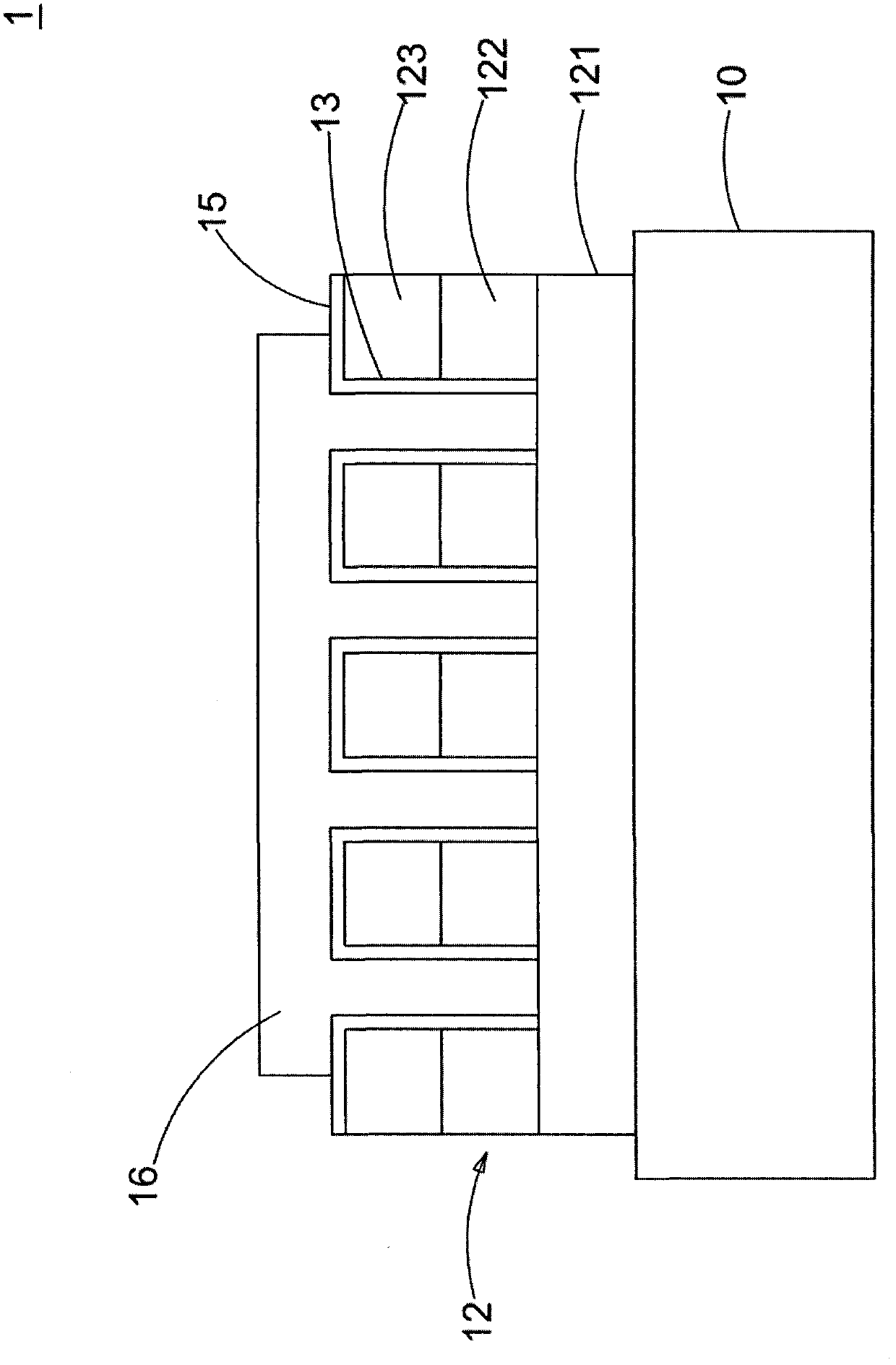

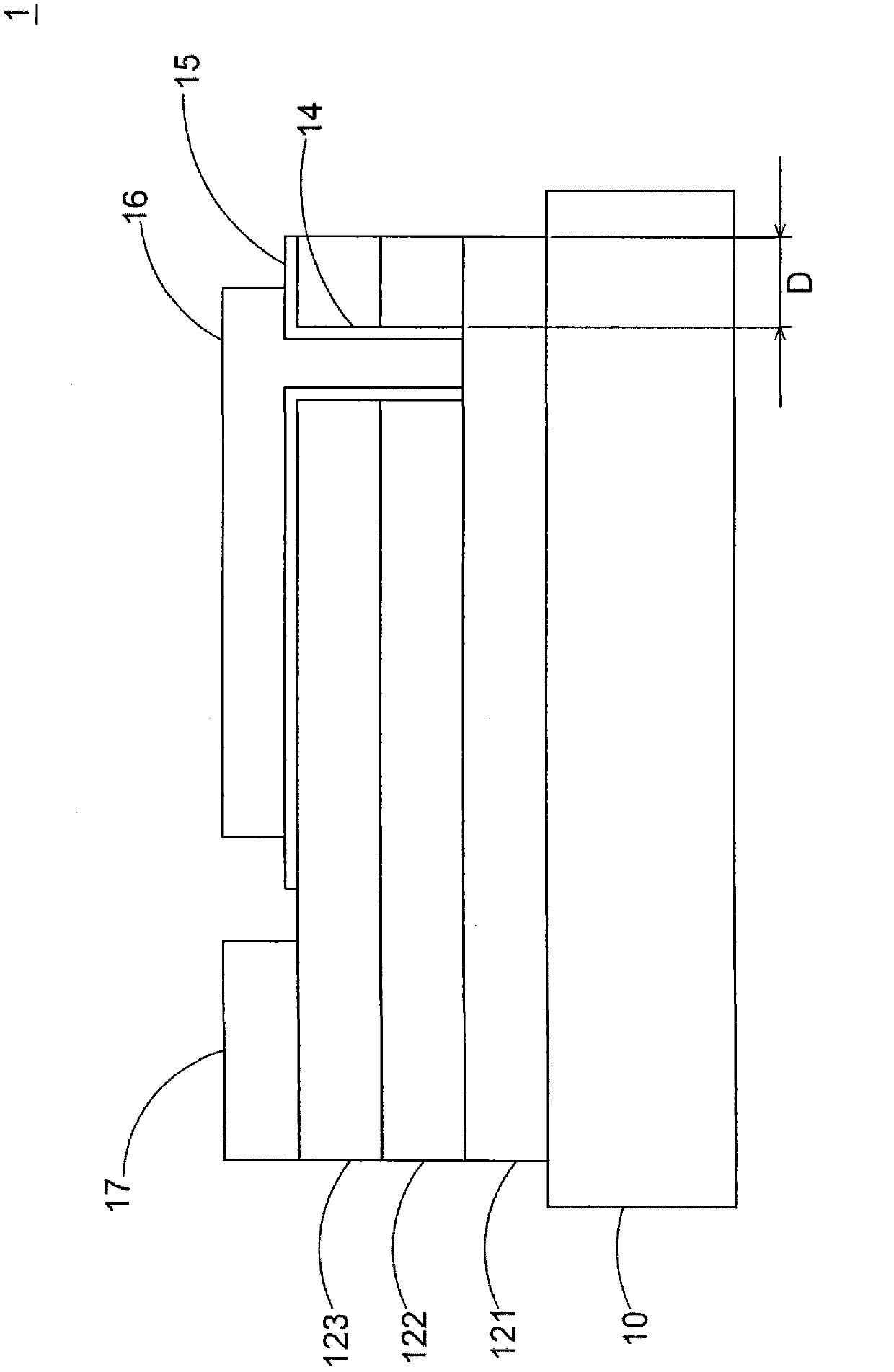

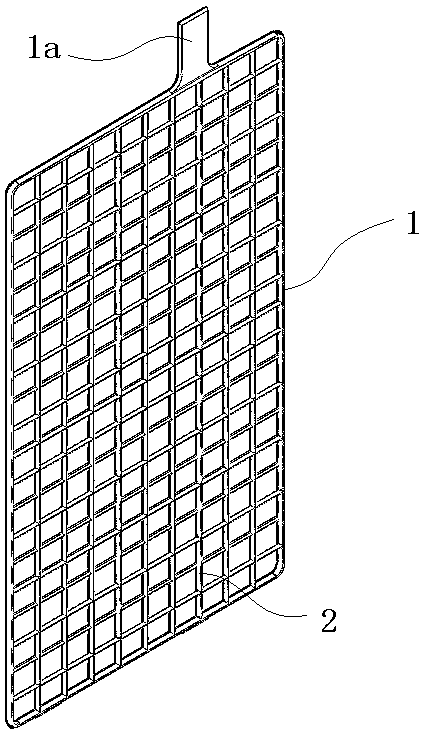

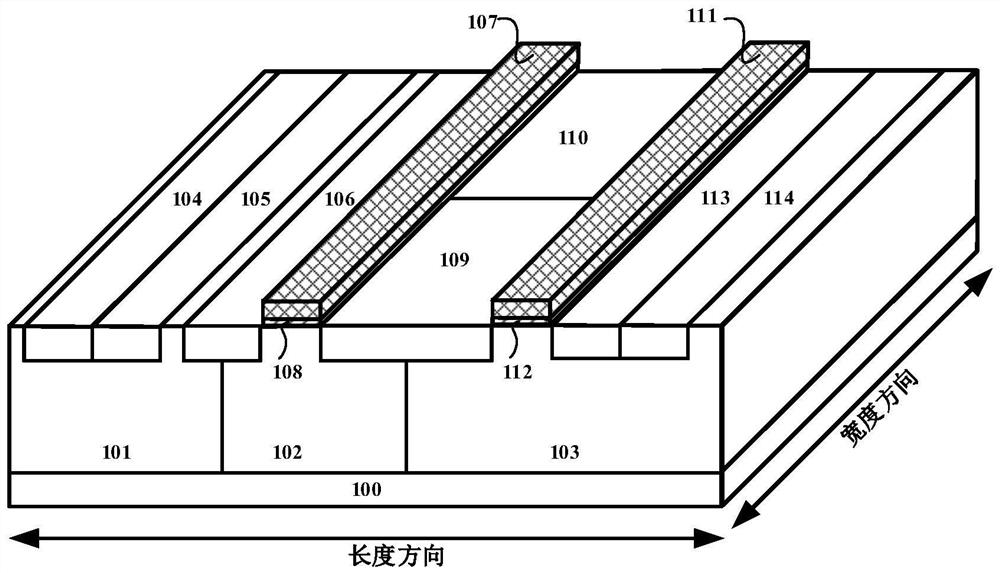

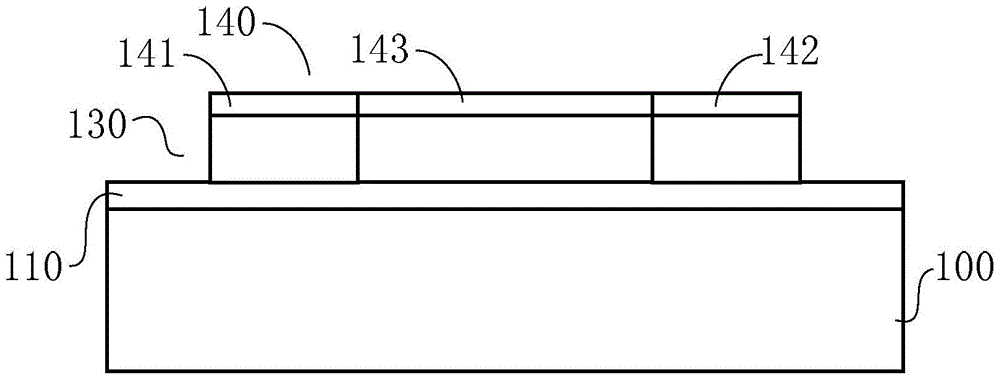

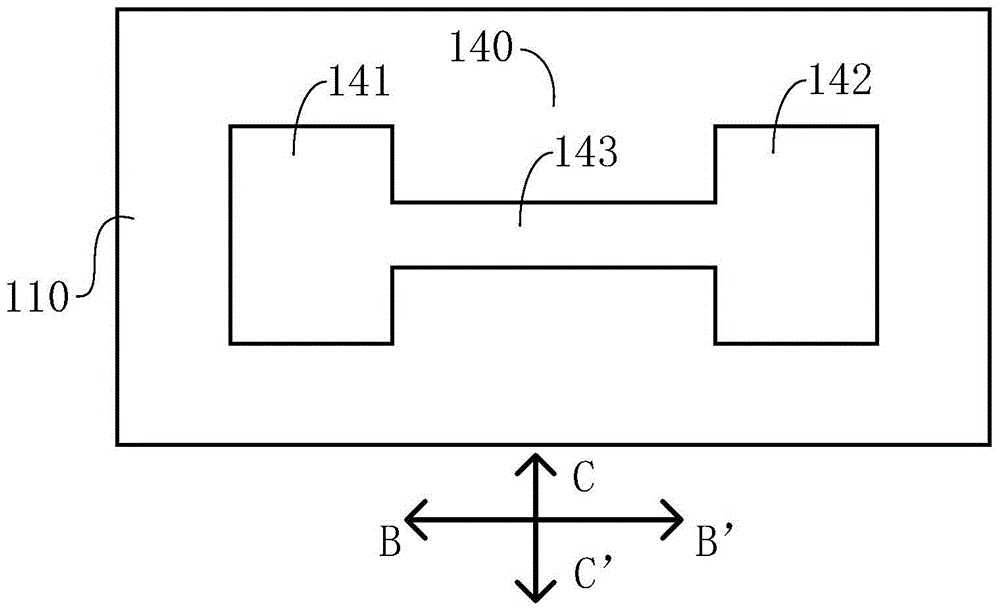

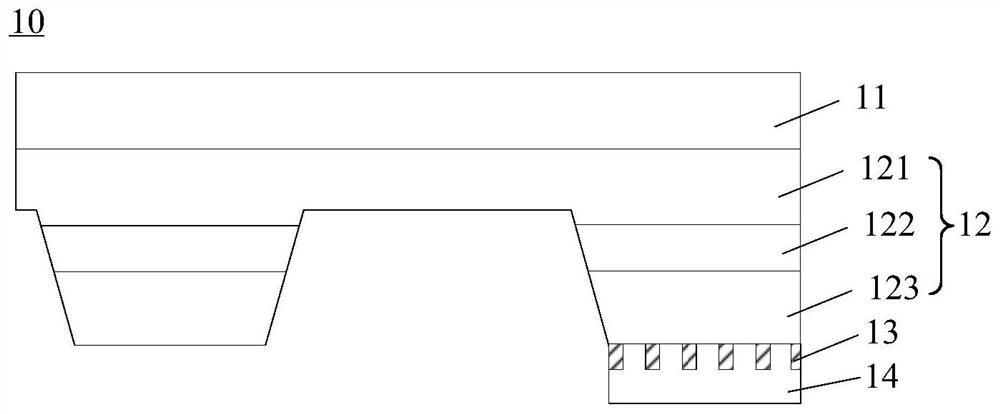

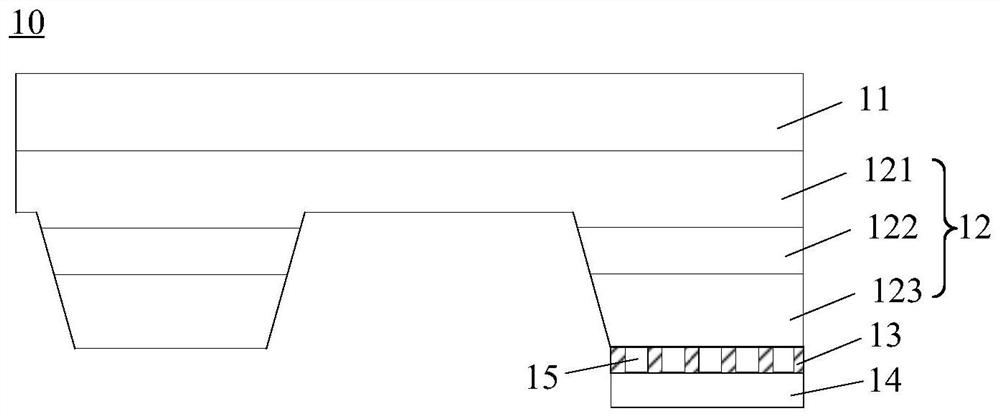

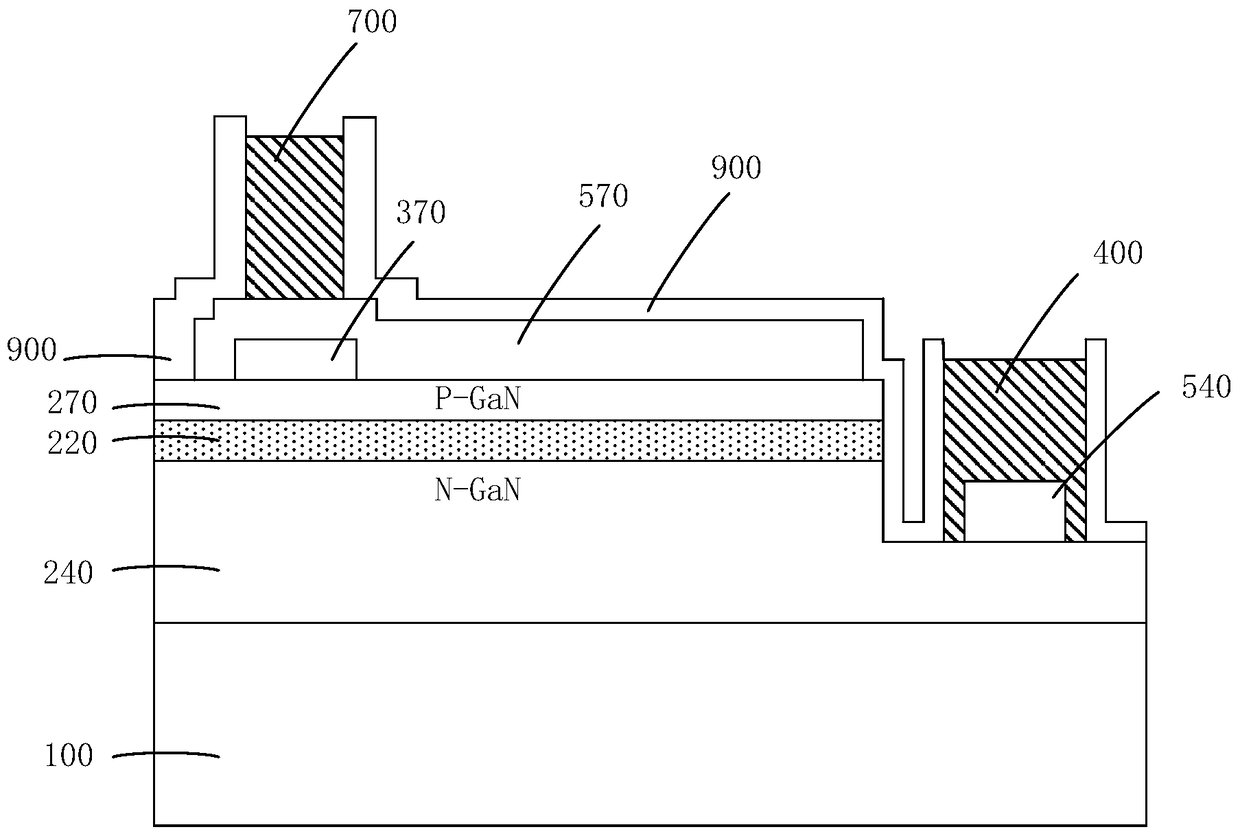

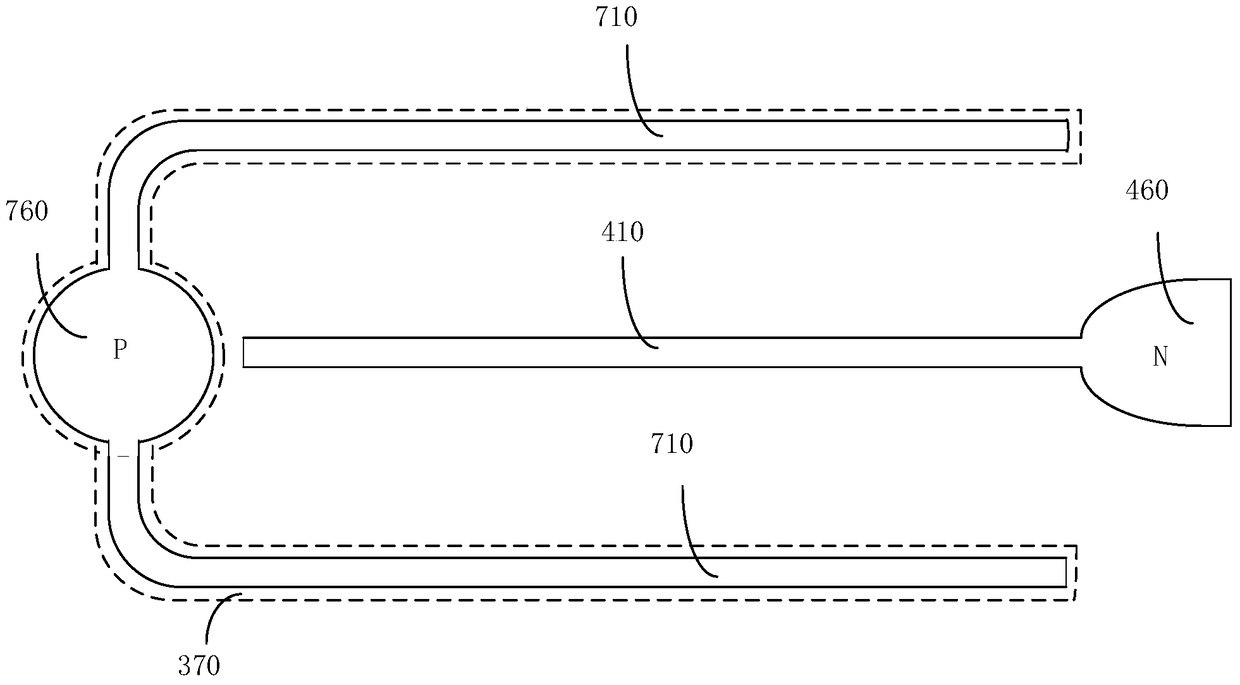

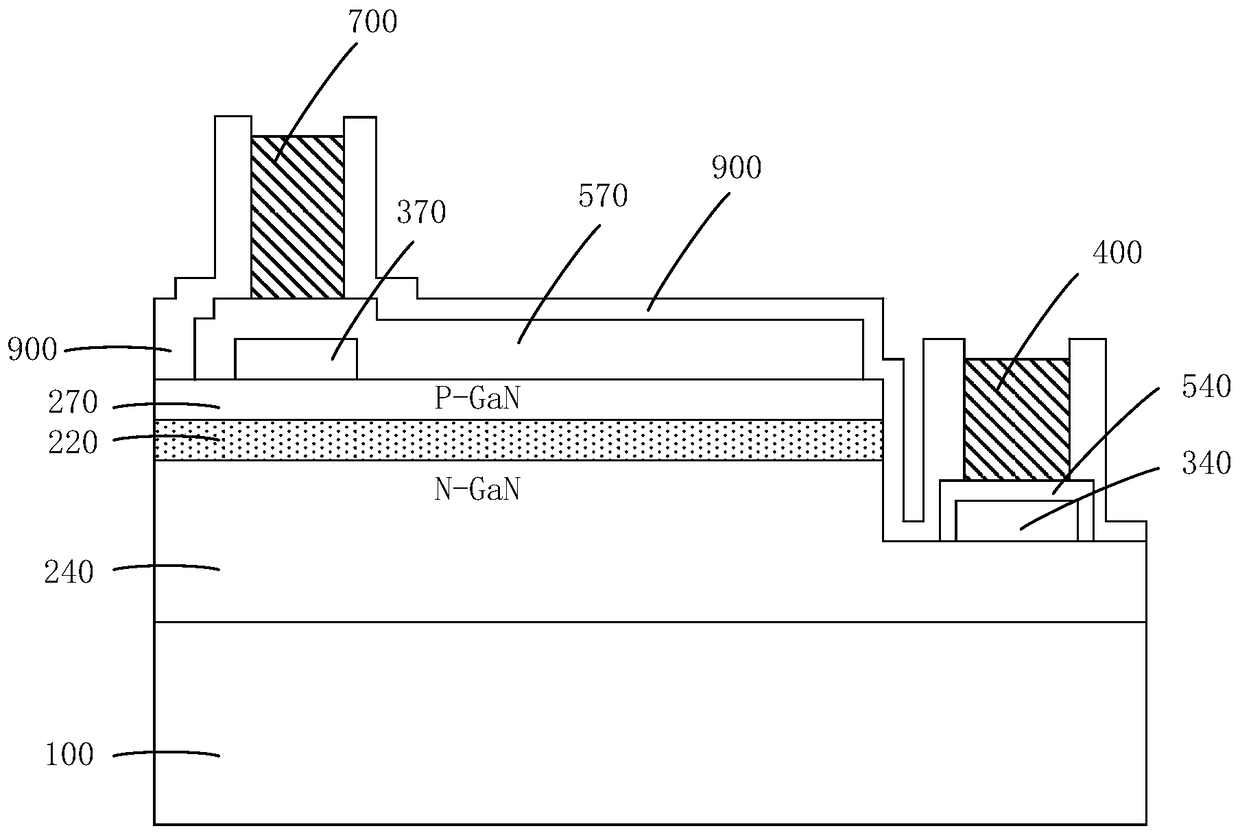

Light emitting diode and flip-chip light emitting diode package

ActiveCN103296166AImprove the uniformity of current distributionImprove luminous efficiencySemiconductor devicesHigh current densityPower flow

The invention provides a light emitting diode (LED) and a flip-chip light emitting diode package. The LED includes a substrate, a first-type doped layer, a light emitting layer, a second-type doped layer, a plurality of first grooves, a second groove, an insulation layer, a first contact, and a second contact. The LED is characterized in that the second groove is connected to one end of each first groove and penetrates the second-type doped layer and the light emitting layer to expose a part of the first-type doped layer. The contact area between the first contact and the first-type doped layer is increased. Therefore, the LED is worked at high current densities without heat accumulation. Moreover, the light emitting area is not reduced and the light emitting efficiency is not affected. The LED is flipped on a package substrate to form a flip-chip LED package.

Owner:NICHIA CORP

Vertical structure LED chip based on photonic crystal and preparation method of vertical structure LED chip

ActiveCN107731971AImprove internal heat fieldImprove uniformityFinal product manufactureNanoopticsPhotonic crystalMature technology

The invention discloses a vertical structure LED chip based on the photonic crystal and a preparation method of the vertical structure LED chip. The chip comprises a Si or Cu substrate layer, an Al monocrystalline metal thin film layer, a p-GaN thin film layer, an i-AlN thin film layer, an n-ZnO layer thin film and a monocrystalline photonic crystal thin film layer. The Si or Cu substrate layer, the Al monocrystalline metal thin film layer, the p-GaN thin film layer, the i-AlN thin film layer, the n-ZnO layer thin film and the monocrystalline photonic crystal thin film layer are down-up successively arranged. By adopting a p-type GaN / n-type ZnO heterostructure, the chip is advantaged by high thermal stability, high chemical stability and mature technology. By using the photonic crystal toreplace the LED chip with the IOT development vertical structure, the structure and making procedures of the chip are simplified, improving of light emitting efficiency of an LED device is facilitated, distribution uniformity of current in the device is improved, the photoelectric performance is excellent and preparation of low-cost and big-power photoelectric devices is facilitated.

Owner:江门市奥伦德光电有限公司 +1

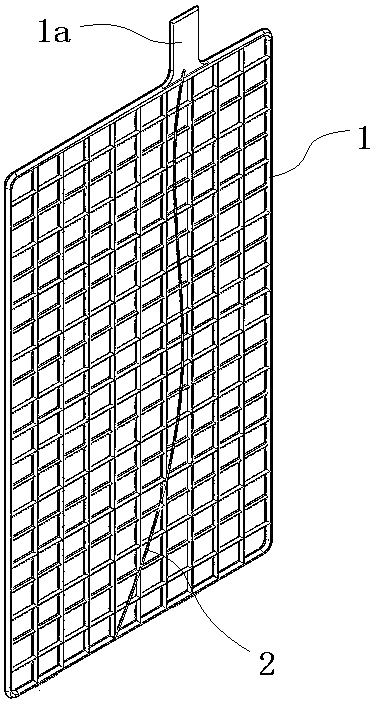

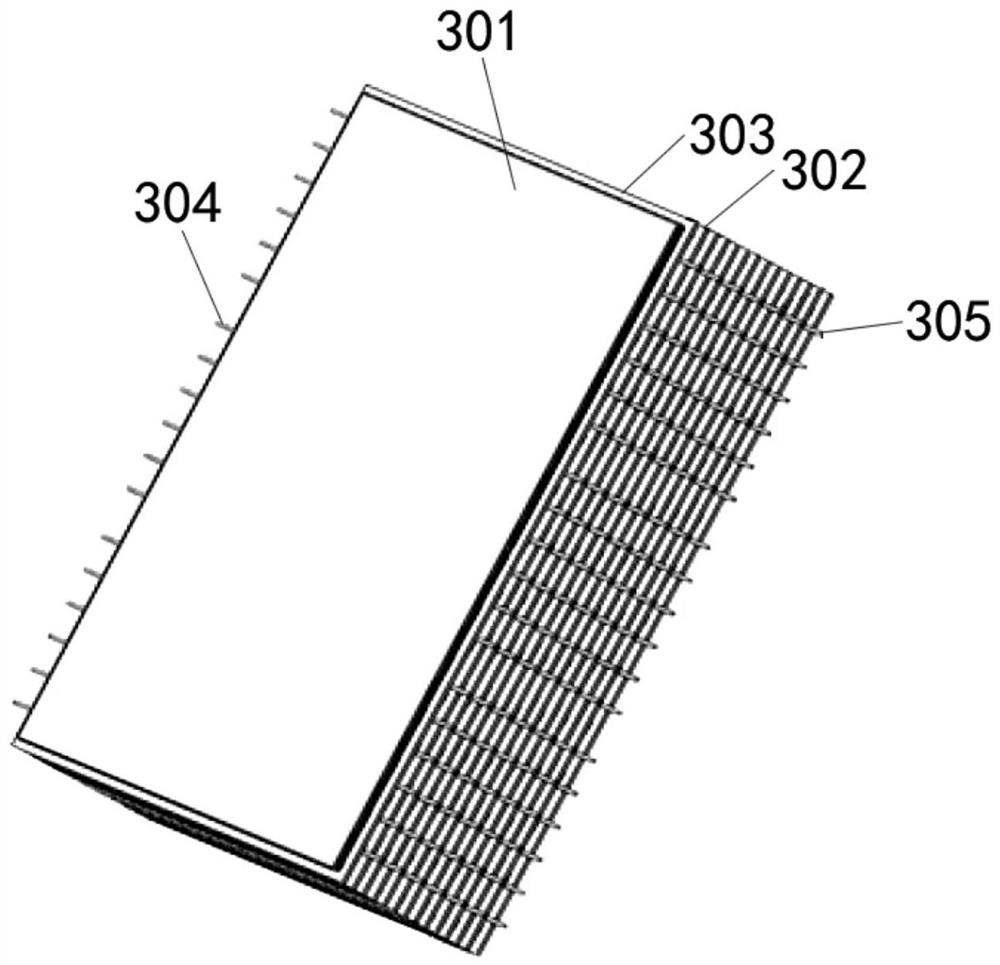

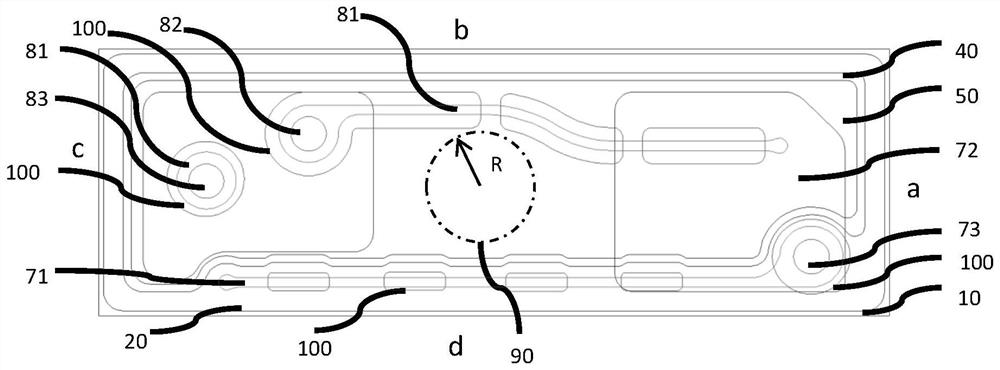

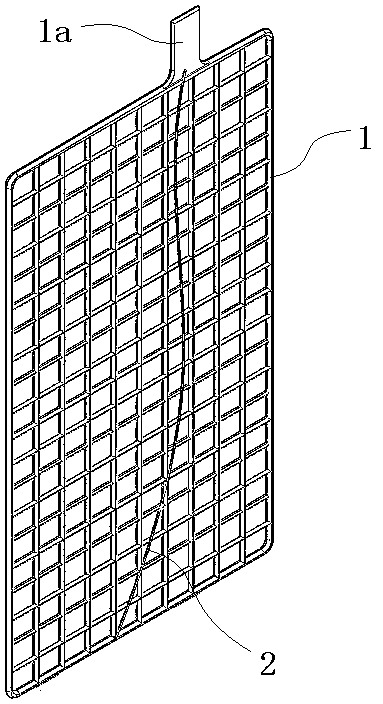

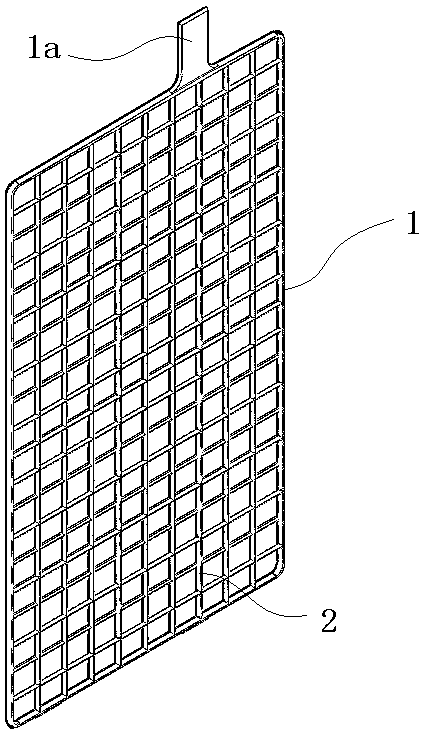

High-conduction grid structure of lead acid storage battery and processing method of high-conduction grid structure

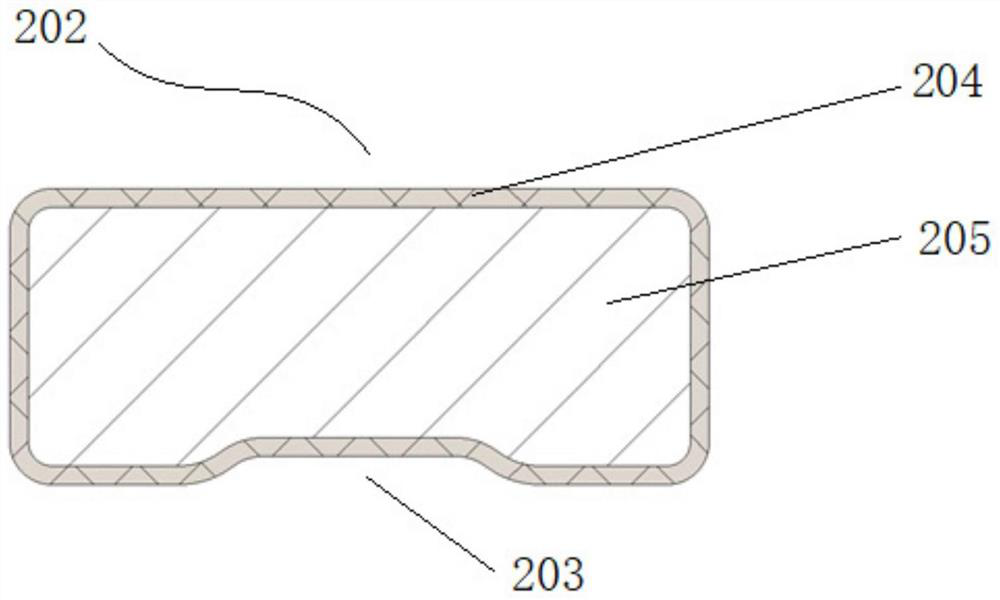

ActiveCN107768682AImprove conductivityGuaranteed charge acceptanceElectrode carriers/collectorsAcid corrosionCharge discharge

The invention discloses a high-conduction grid structure of a lead acid storage battery and a processing method of the high-conduction grid structure. The grid structure comprises a grid, wherein a tab is arranged at one side of the grid, at least one high-conduction rib is arranged on the grid, one end of the high-conduction rib is fixedly connected with the tab, and the other end of the high-conduction rib is fixedly connected with a side edge of the grid. The processing method comprises the following steps of (a) covering an acid corrosion-resistant material on a surface of the high-conduction rib, and cutting the high-conduction rib after being covered with the acid corrosion-resistant material to segments; (b) fixing the high-conduction rib which is cut to segments and the grid; and (c) detecting the high-conduction rib and the grid which are fixed so that the high-conduction rib and the grid are enabled to be in a conduction state. The invention aims to provide the high-conduction grid structure of the lead acid storage battery and the processing method of the high-conduction grid structure, which can be used for improving the electrical conducted of the grid and current uniformity during the charge-discharge process.

Owner:CHAOWEI POWER CO LTD

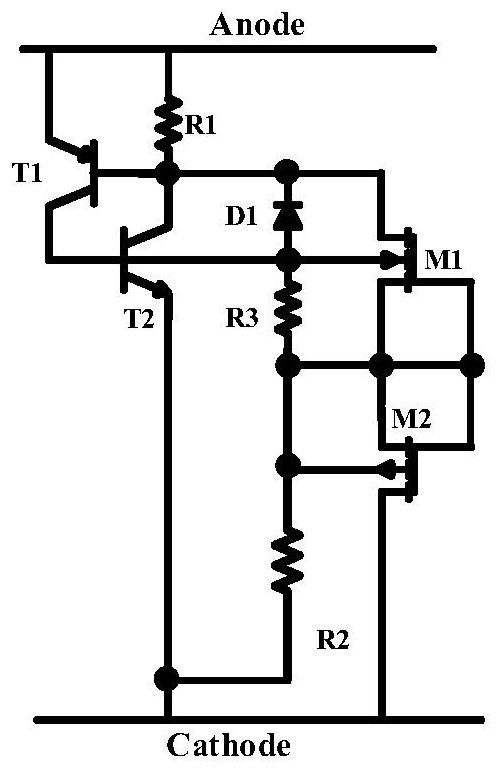

High-voltage protection integrated circuit of CMOS auxiliary triggering SCR structure

ActiveCN112563261AOpen fastLower the trigger voltageTransistorSolid-state devicesCMOSDischarge efficiency

The invention provides a high-voltage protection integrated circuit of a CMOS auxiliary triggering SCR structure, and belongs to the field of electrostatic discharge and surge protection of integratedcircuits. The high-voltage protection integrated circuit comprises an embedded CMOS, an SCR structure and a metal wire. By utilizing the advantage of strong ESD robustness of the SCR, quick responseand latch-up resistance can be realized by embedding the MOS tube structure in the circuit, and higher ESD current discharge efficiency can be achieved by parallel conduction of the SCR, a parasitic triode and a MOS tube. Besides, through optimization of a circuit unit structure and a layout design, the number of masks is reduced, and better process compatibility and lower manufacturing cost can be considered while a smaller chip area is occupied.

Owner:JIANGNAN UNIV

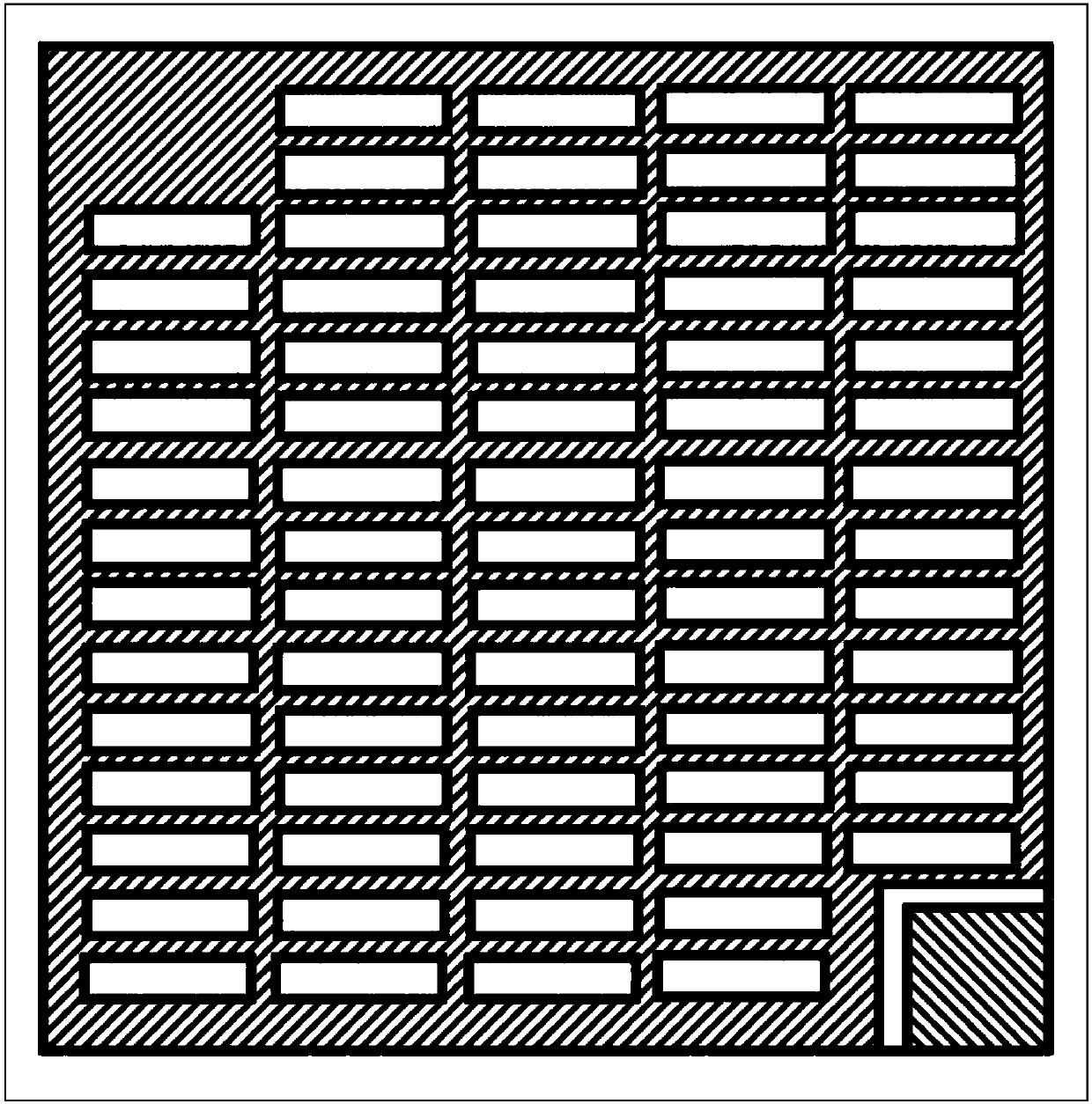

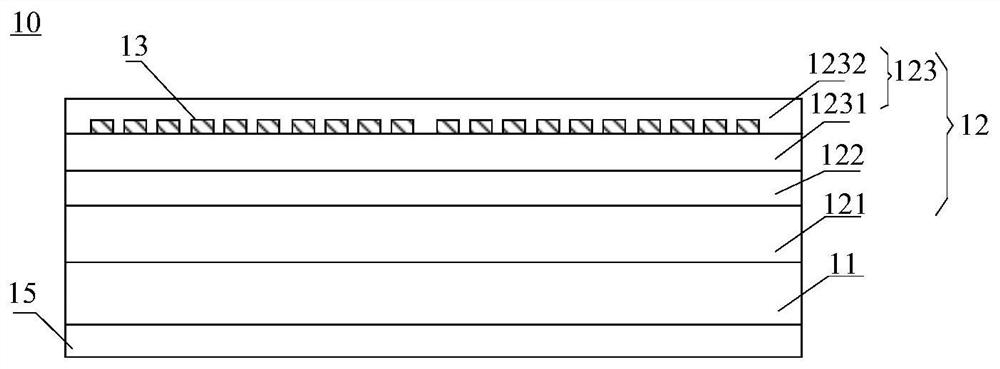

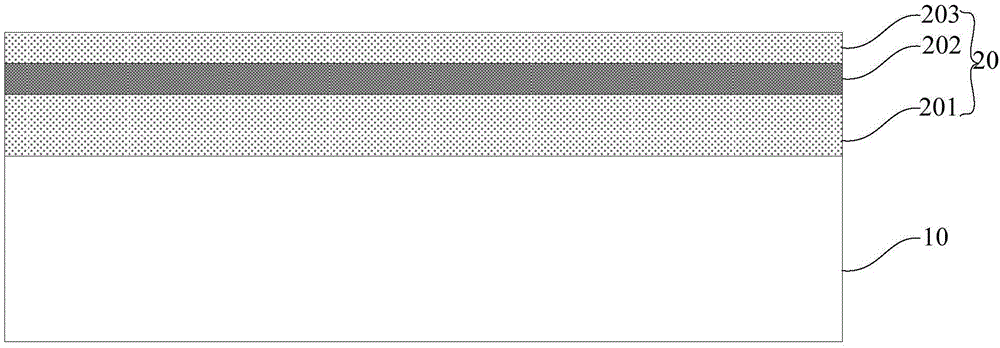

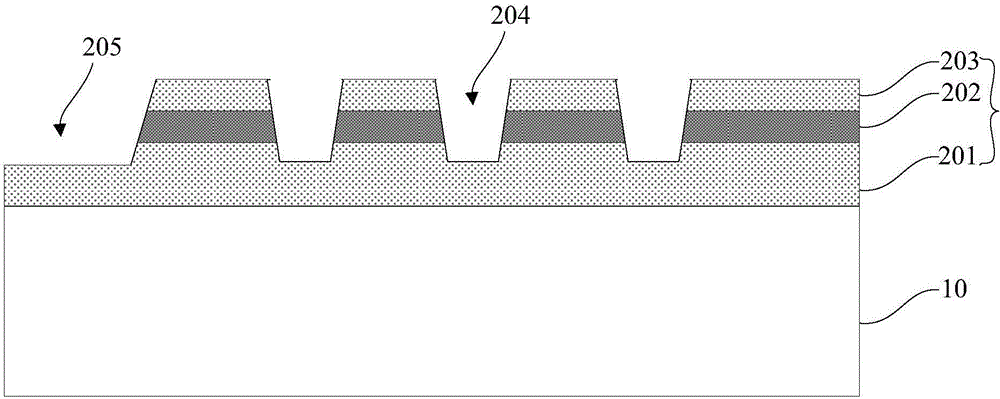

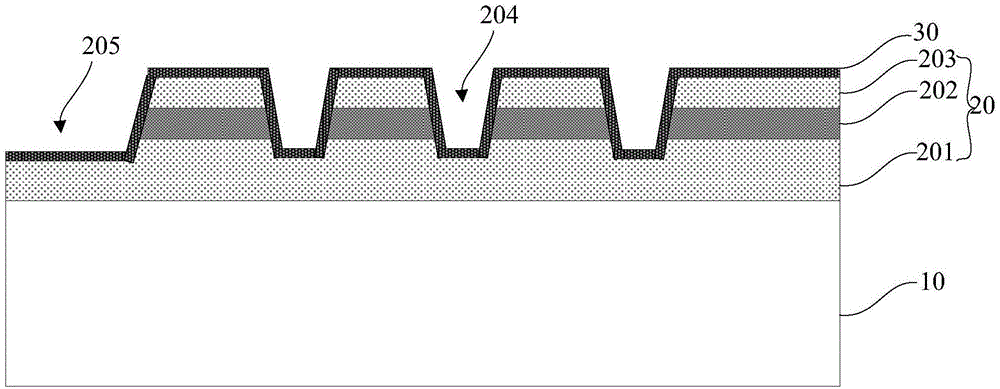

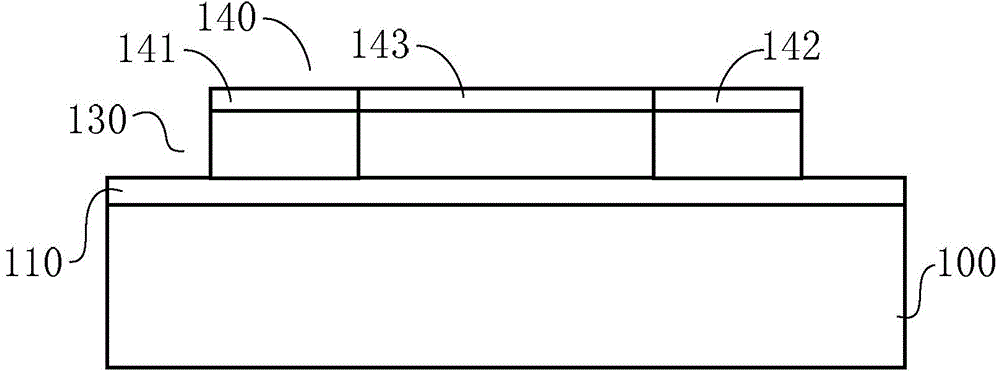

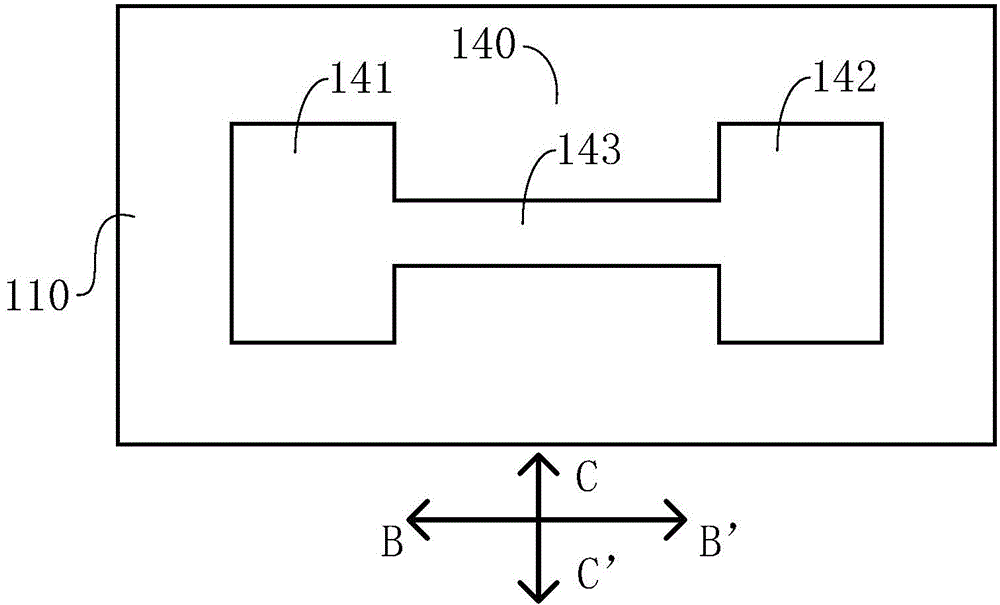

Light-emitting diode and manufacturing method thereof

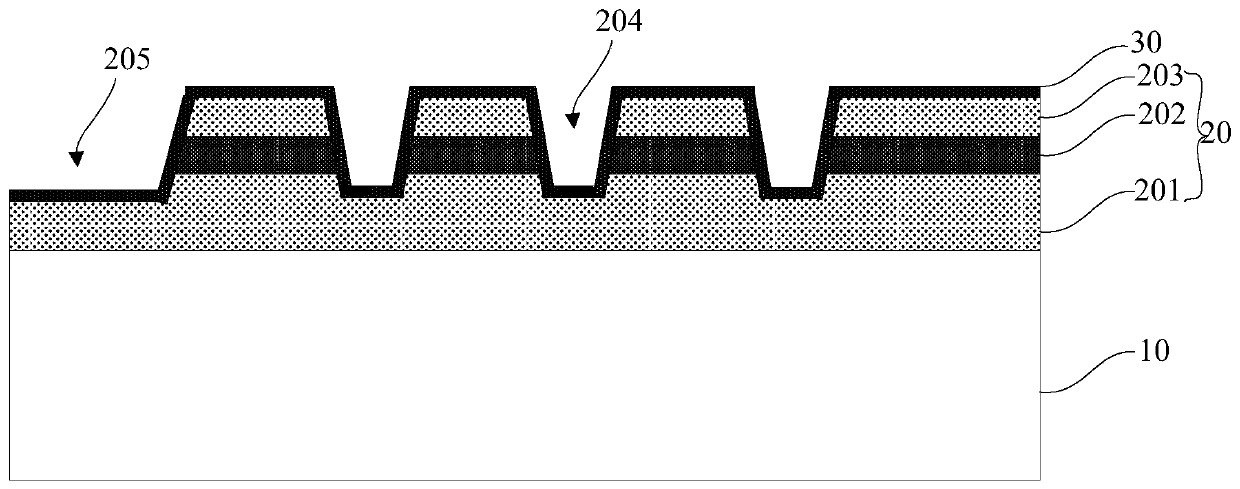

ActiveCN112670386AEvenly distributedImprove the uniformity of current distributionSemiconductor devicesCurrent distributionLight-emitting diode

The invention relates to the field of light-emitting diodes, and particularly discloses a light-emitting diode and a manufacturing method thereof. The light-emitting diode comprises a substrate, a light-emitting epitaxial layer and a plurality of electrode patterns; the light-emitting epitaxial layer comprises a first semiconductor layer, an active light-emitting layer and a second semiconductor layer which are sequentially stacked on the main surface of one side of the substrate; and the plurality of electrode patterns are buried in the first semiconductor layer or the second semiconductor layer, are connected with one another and are distributed in a grid shape. Through the mode, the technical problems of uneven current diffusion, uneven thermal diffusion and uneven light extraction of the light-emitting diode in the prior art can be solved, the current distribution is effectively improved, and the current distribution uniformity is improved.

Owner:纳微朗科技(深圳)有限公司

Manufacturing method of light-emitting diode

ActiveCN104681672AReduce current congestionImprove light extraction efficiencySemiconductor devicesDislocationEngineering

The invention provides a manufacturing method of a light-emitting diode. The manufacturing method comprises the following steps of: (1) forming a light-emitting epitaxial structure on the surface of a growth substrate; (2) simultaneously etching an N electrode platform and a plurality of holes which are located between the N electrode platform and a P electrode in each light-emitting unit; (3) forming a plurality of cutting grooves in a tangent manner; (4) depositing SiO2 layers, and removing the SiO2 layer in each hole; (5) corroding to form a plurality of dislocation pits at the bottom of respective holes by using a chemical corrosion method, and simultaneously removing residues in each cutting groove; (6) forming the SiO2 layers again; (7) removing part of the SiO2 layers, and reserving the SiO2 layers at the bottom and the side wall of each hole and below the P electrode; (8) forming a current spreading layer; (9) preparing the P electrode and an N electrode. According to the manufacturing method, by forming the holes between the P electrode and the N electrode and further forming the dislocation pits at the bottoms of the holes, the current congestion of the light-emitting diode can be reduced, the current distribution uniformity is improved, and the luminous efficiency of the light-emitting diode is improved.

Owner:EPILIGHT TECH

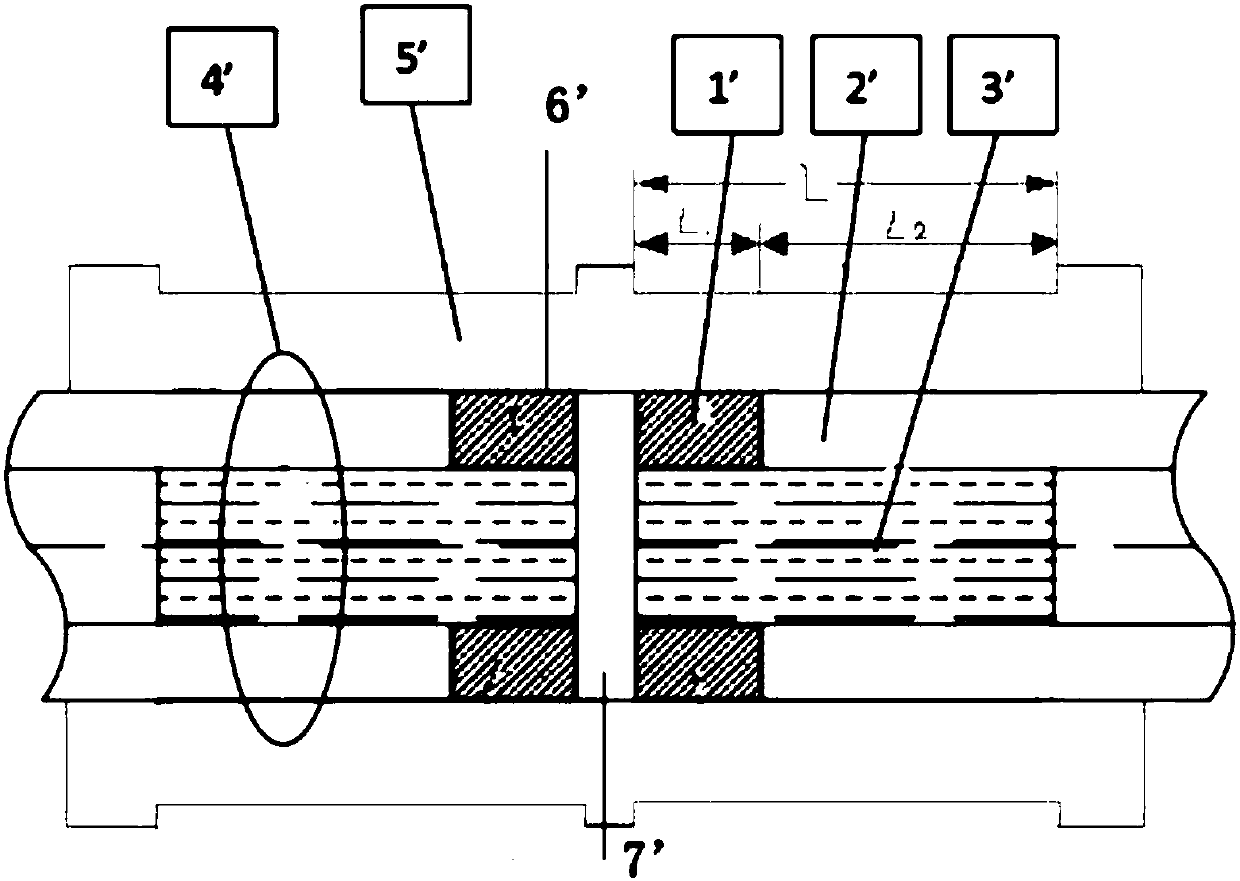

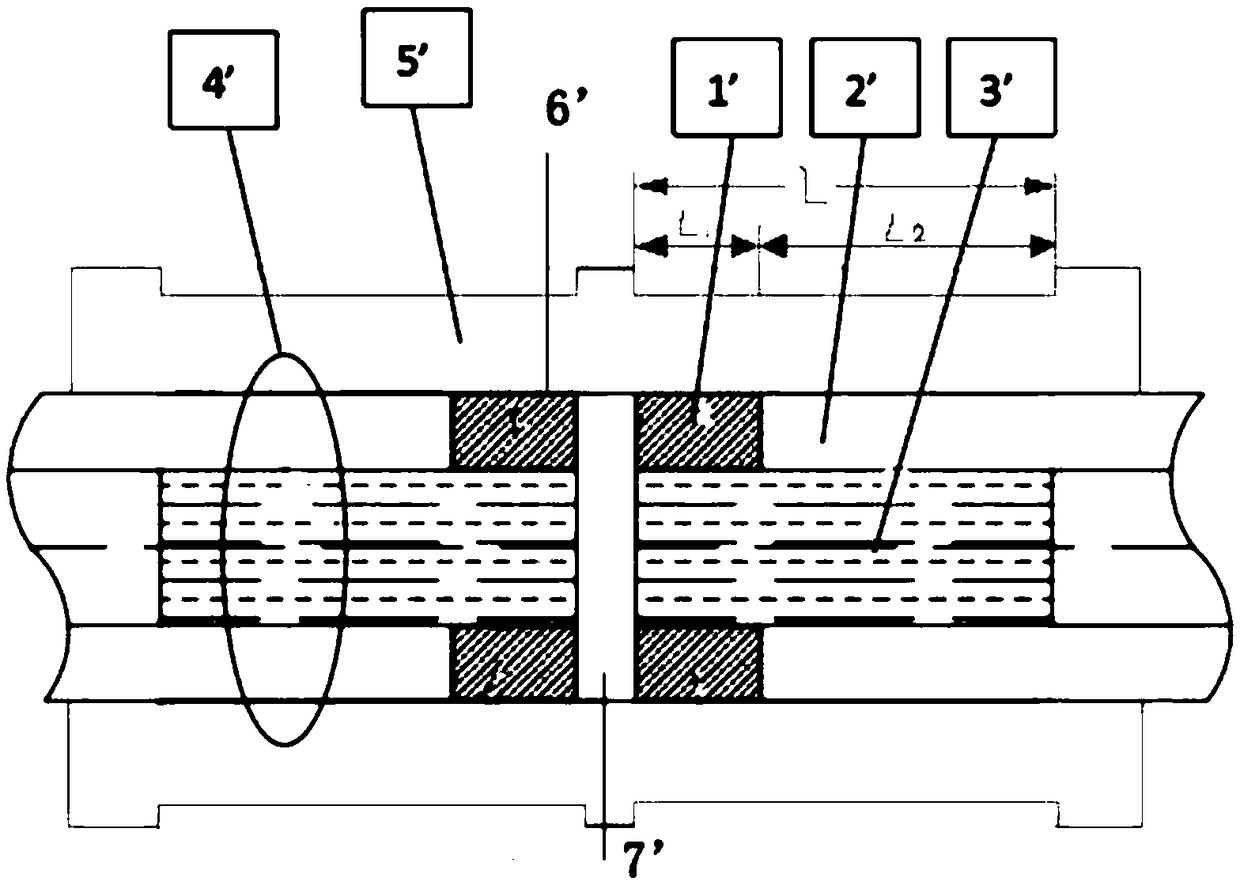

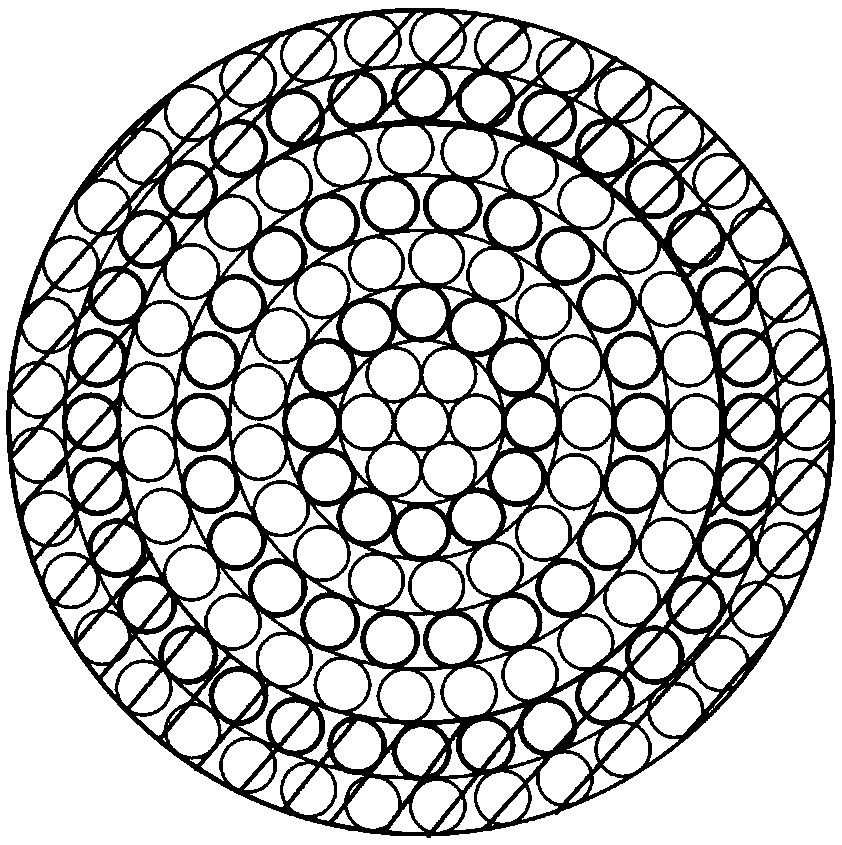

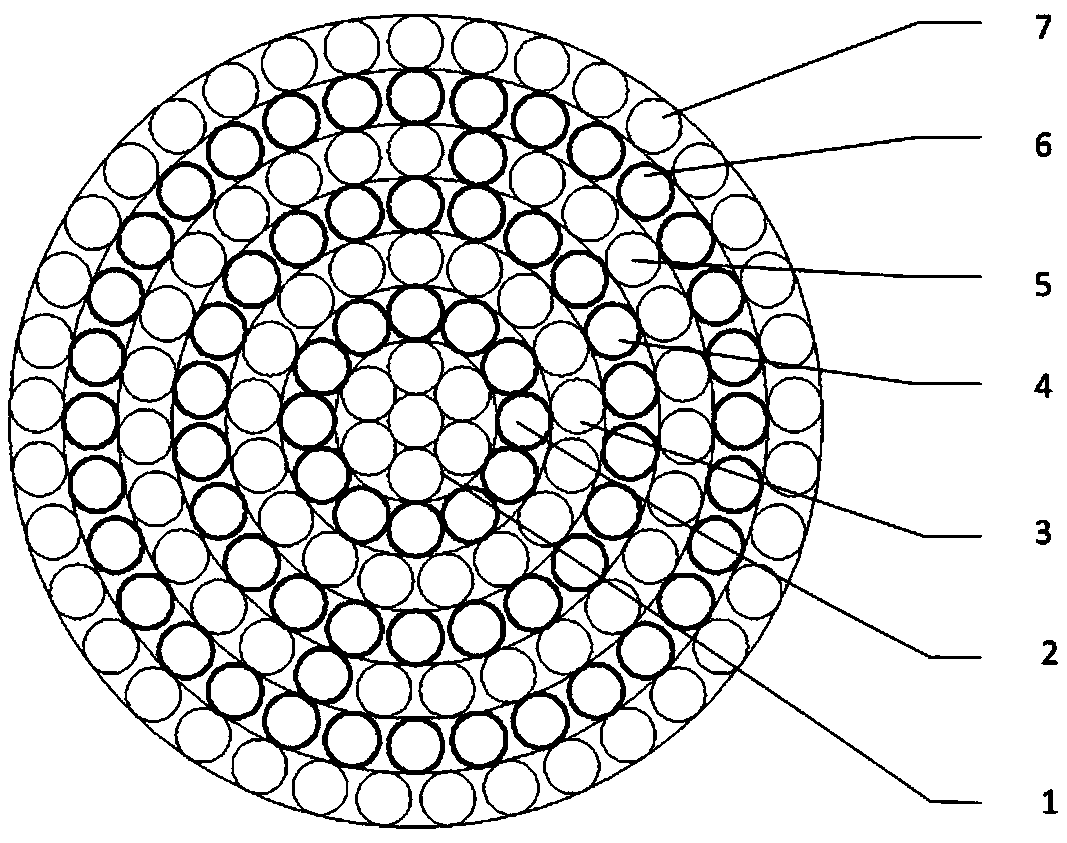

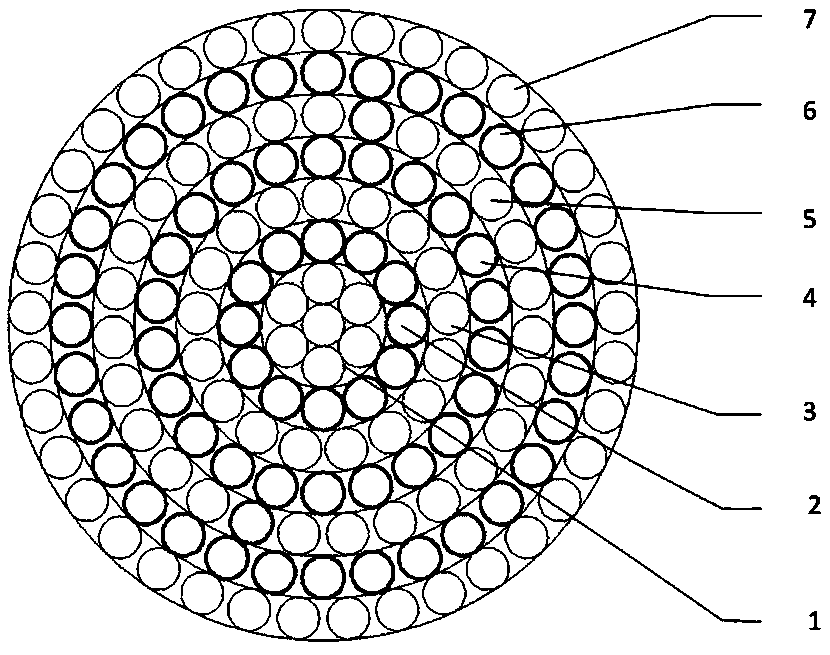

Crimping type cable conductor connector with current sharing effect and preparation method

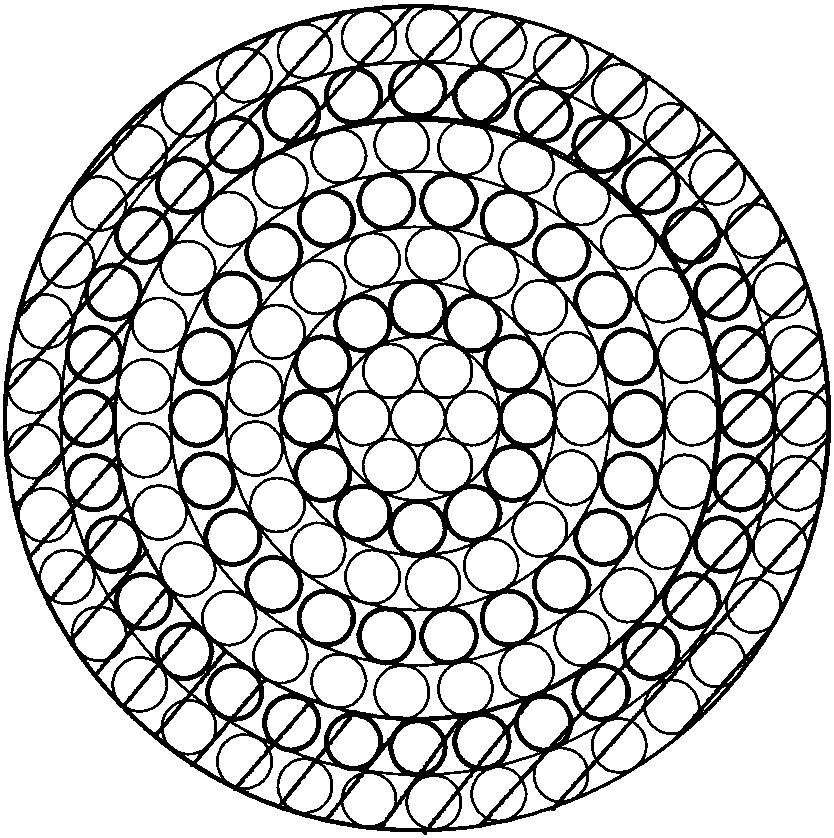

ActiveCN107611627AReduce skin effectReduce AC resistanceLine/current collector detailsConnections effected by permanent deformationElectrical resistance and conductancePower cable

The invention belongs to the fields of a power transmission line and a power cable, and particularly relates to a crimping type cable conductor connector with a current sharing effect and a preparation method. Each layered insulating conductor consists of a first cylinder positioned in the centre of the conductor, and a second cylinder and a third cylinder with hollow-out central parts and arranged outside the first cylinder in a sleeving manner; the layered insulating conductor is inserted into a hollow conductor connecting pipe from the two ends of the conductor connecting pipe; in a crimping process, a crimping die surrounds the upper and lower sides of a crimping section of the conductor connecting pipe; and the cable conductor connector is extruded by die closing of the crimping die,and the conductor connecting pipe and the layered insulating conductor are subjected to micro deformation. By virtue of the crimping type cable conductor connector, the alternating current resistanceof the large-section cable conductor with the layered insulating structure in the conductor connector position can be lowered, so that the problem of temperature rise in the conductor and the connector positions when the large-section layered insulating conductor is applied can be overcome.

Owner:STATE GRID CORP OF CHINA +3

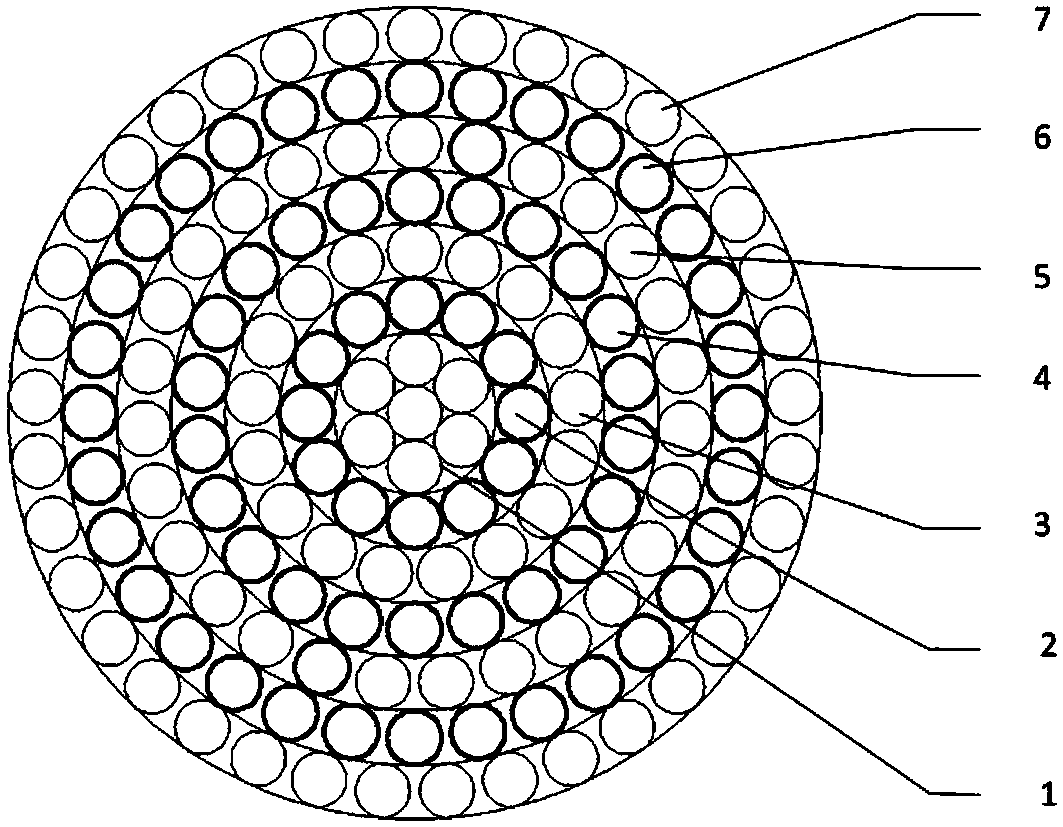

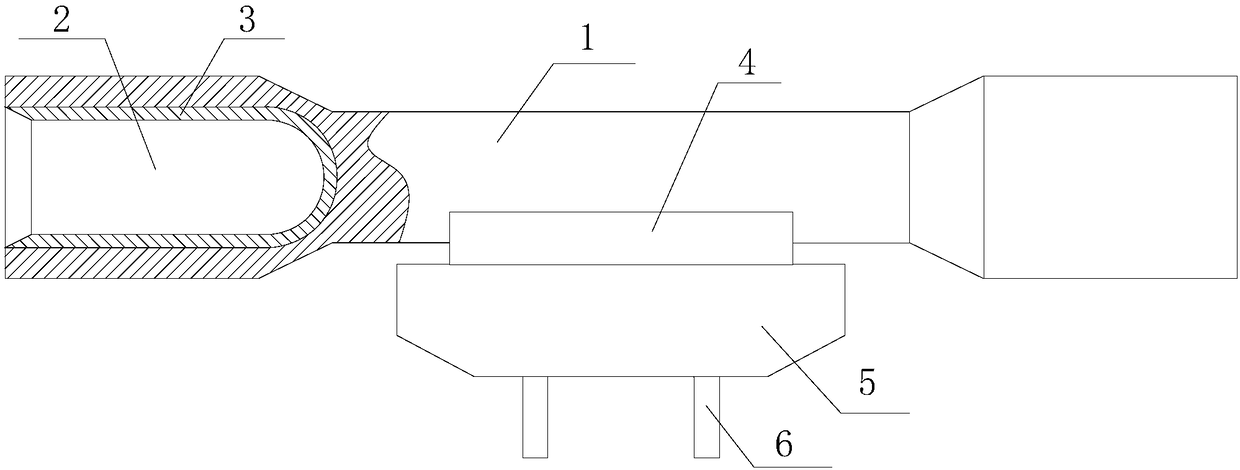

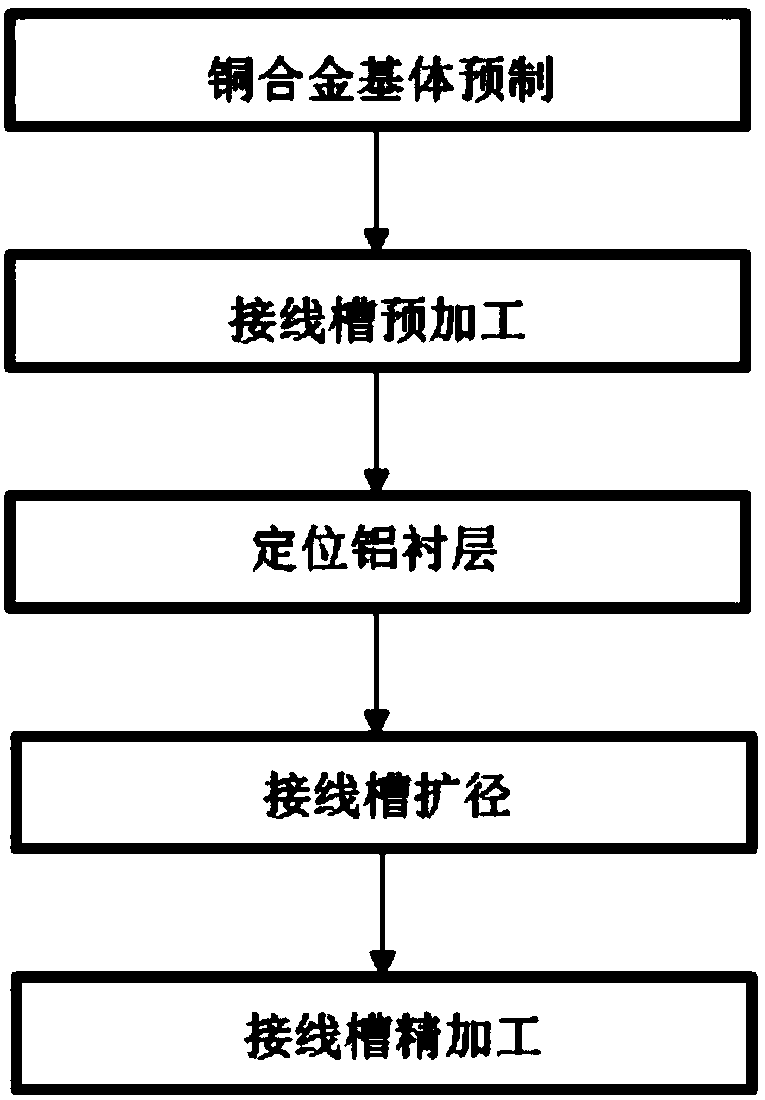

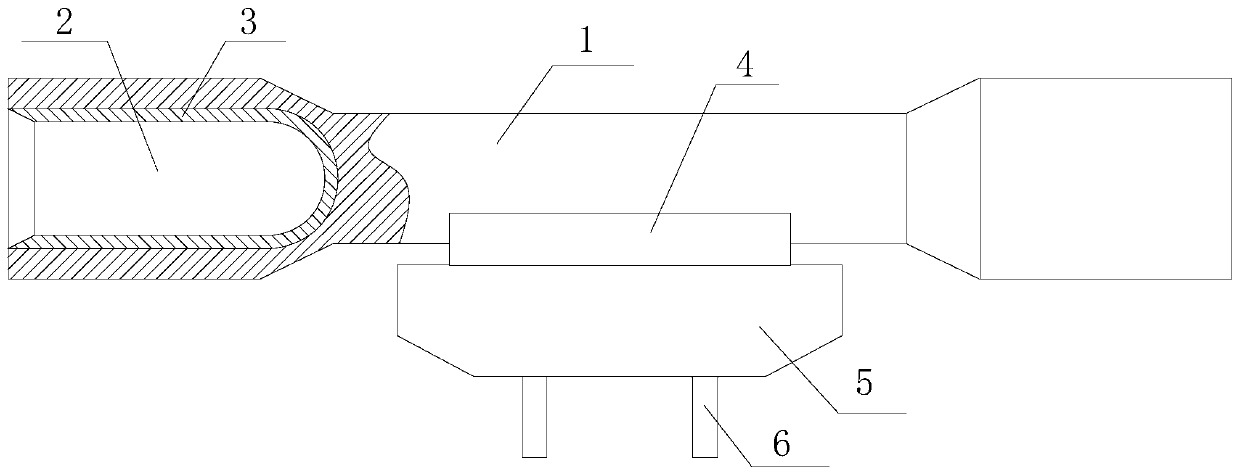

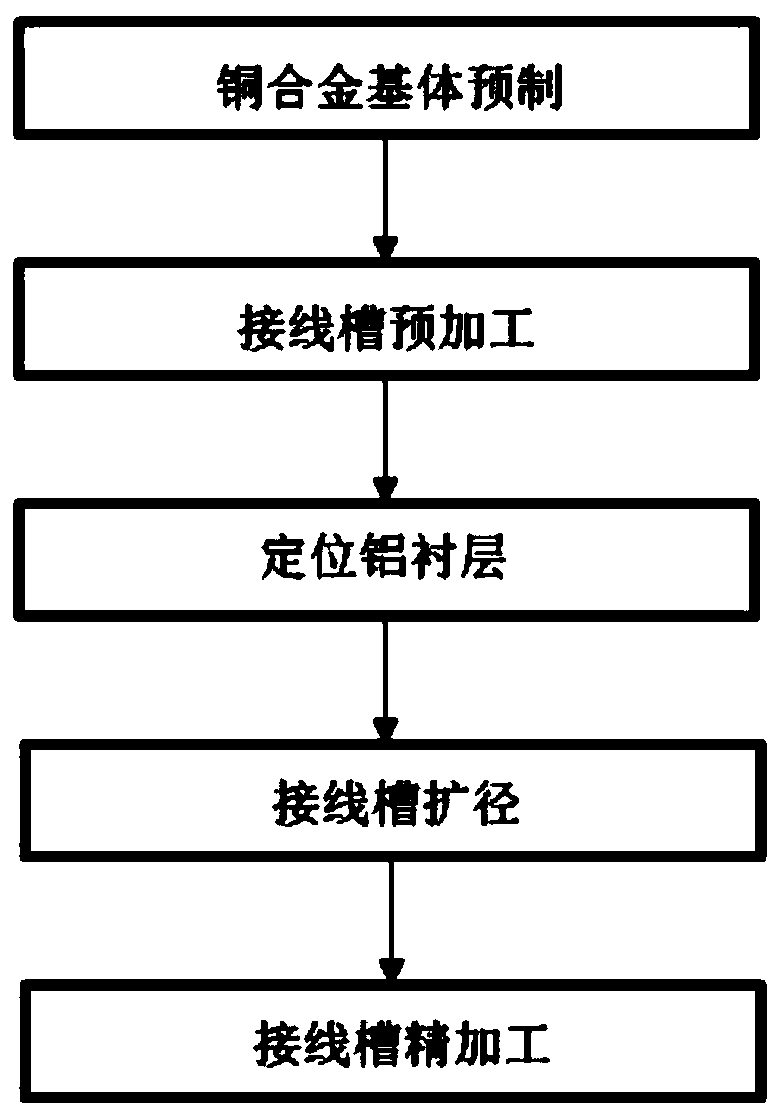

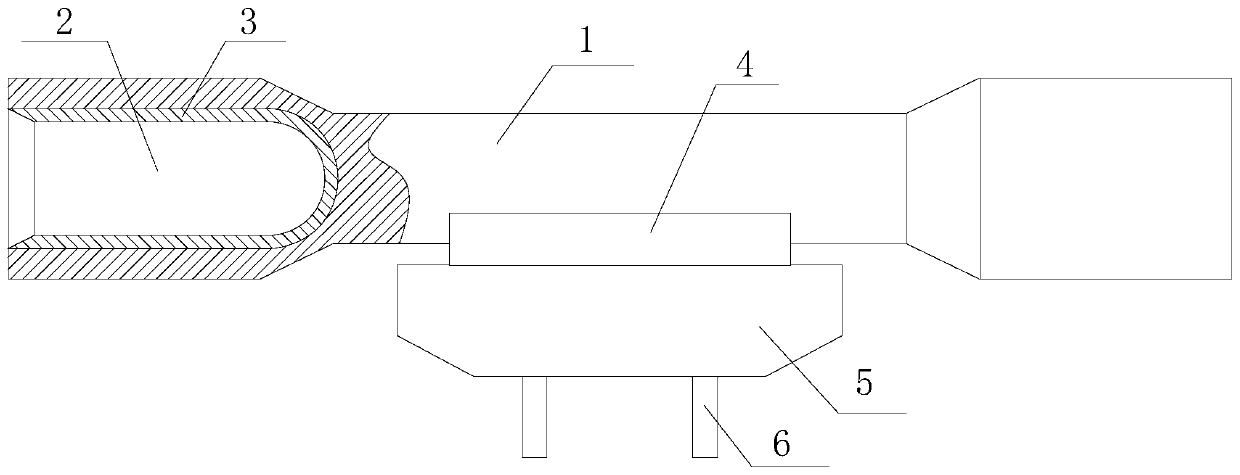

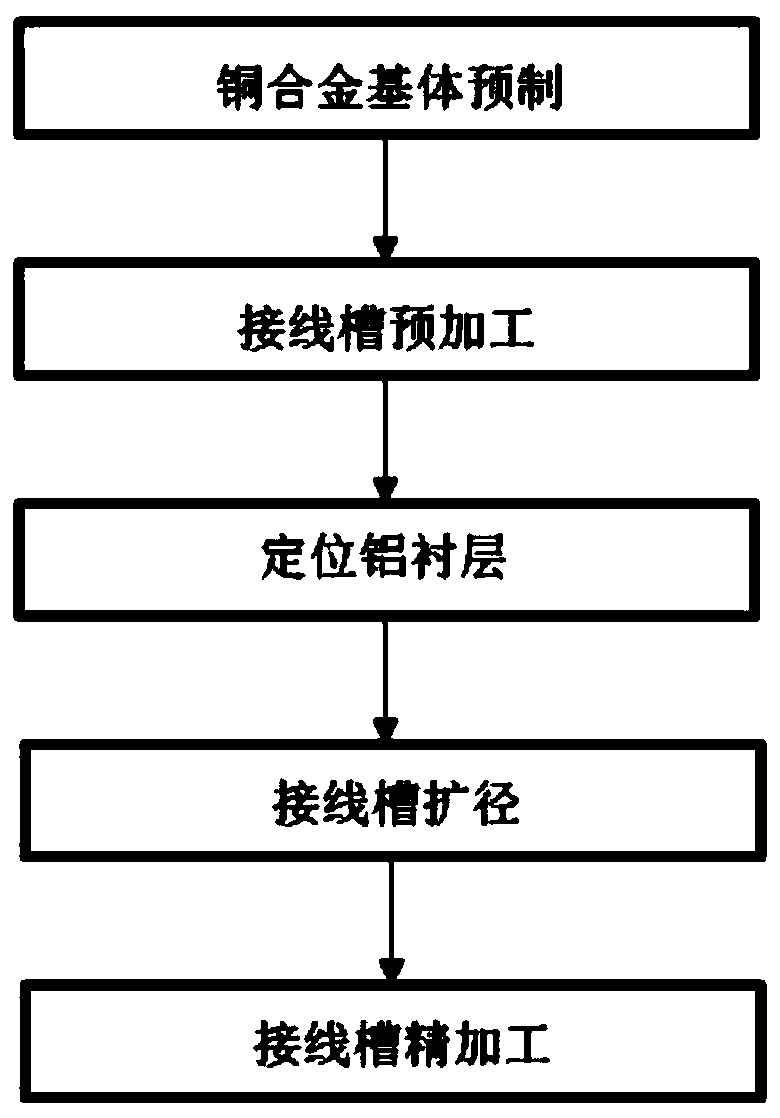

Preparation method of aluminum alloy high-voltage cable aluminum copper composite terminal

ActiveCN108493735AEasy to prepareEasy to operate and masterContact member manufacturingMetal/alloy conductorsCorrosionOperational stability

The invention discloses an aluminum alloy high-voltage cable aluminum copper composite terminal. The aluminum alloy high-voltage cable aluminum copper composite terminal comprises a copper alloy substrate and connecting grooves formed in the two ends of the copper alloy substrate; the connecting grooves adopt a U-shaped groove-shaped cross section and are symmetrically distributed along the axis of the copper alloy substrate; the length of the connecting grooves is 1 / 5-1 / 2 of that of the copper alloy substrate; the inner surfaces of the connecting grooves are both distribute with aluminium alloy lining layers; and the thickness of the aluminium alloy lining layers is 1 / 4-3 / 4 of that of the connecting groove side wall; and the preparation method comprises four steps of copper alloy substrate prefabrication, connecting groove pre-processing, aluminum lining layer positioning, connecting groove diameter expansion and connecting groove fine processing. By virtue of the aluminum alloy high-voltage cable aluminum copper composite terminal and the preparation method thereof, the connecting structural strength, the impact resistance performance, the corrosion resistance performance and thehigh temperature resistance performance between the terminal and the cable can be improved effectively, so that the mechanical structural strength of the terminal is highly improved; and in addition,the overload capacity of the terminal is improved effectively, and current distribution uniformity is improved, thereby highly improving reliability and operational stability of the power cable connection operation.

Owner:江西杰洋科技有限公司

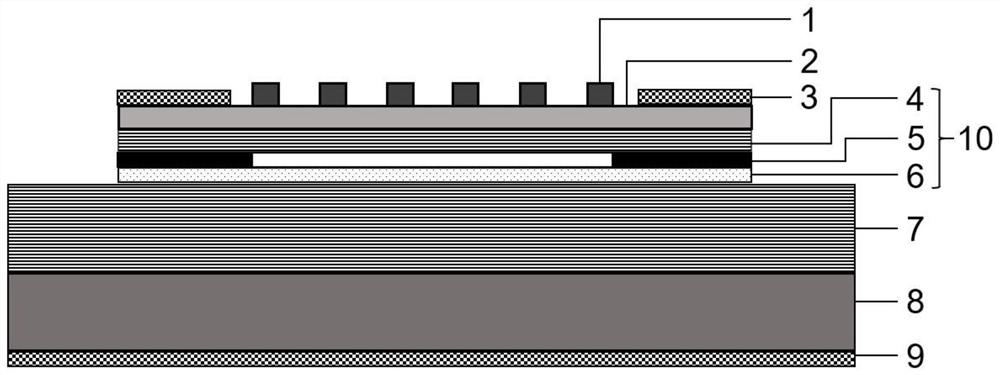

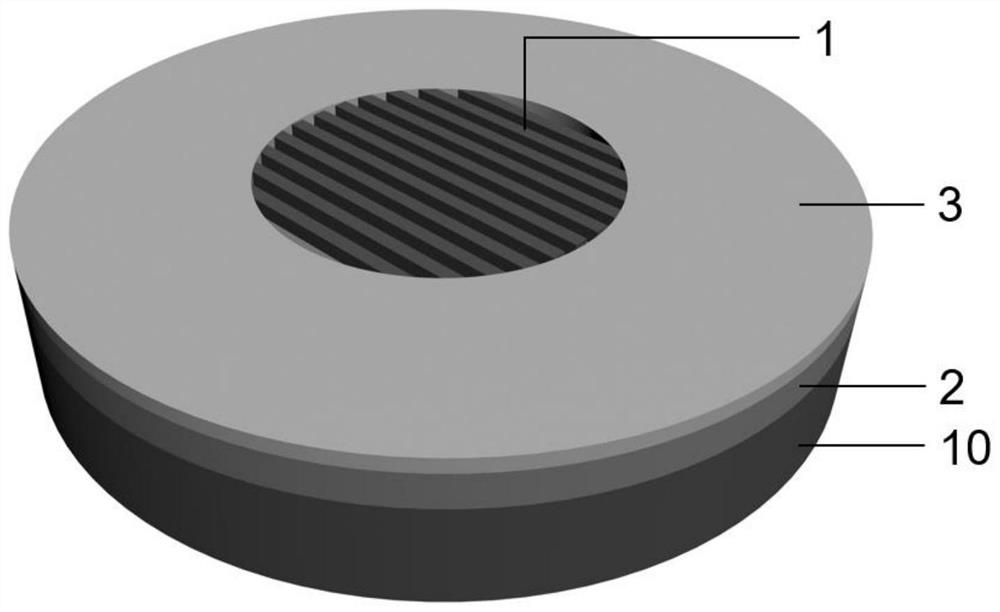

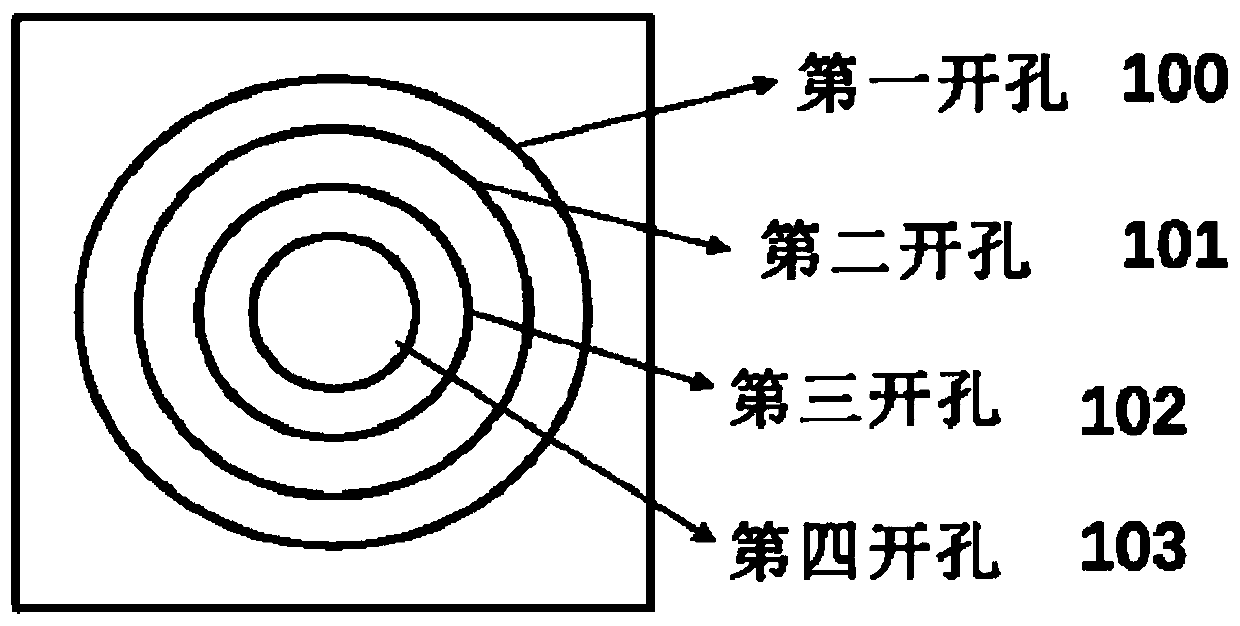

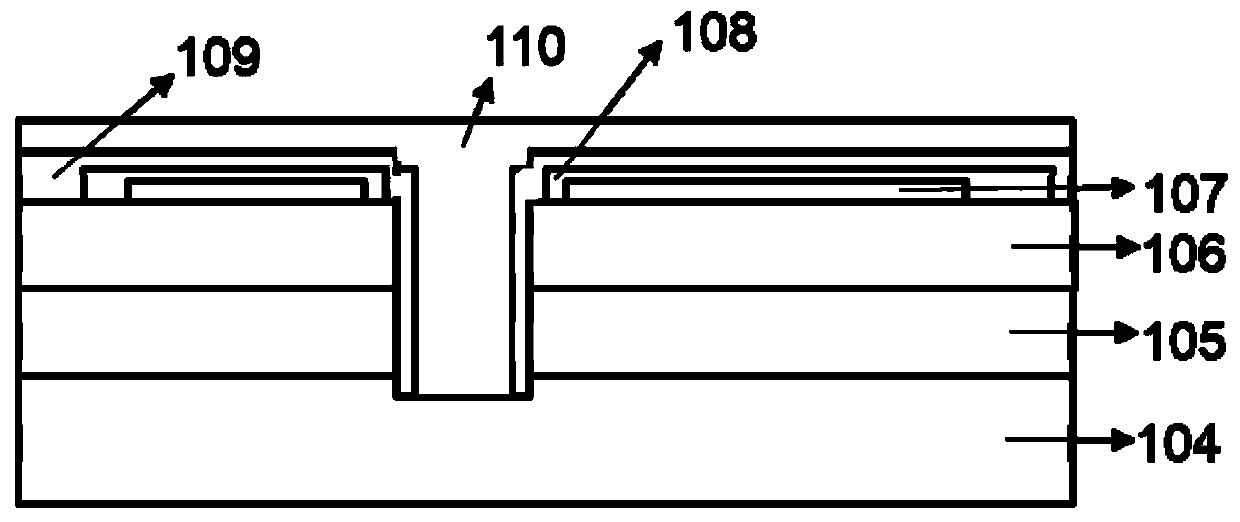

Sub-wavelength grating and vertical cavity surface emitting laser

PendingCN113488846AImprove reliabilityHigh beam qualityLaser detailsSemiconductor lasersVertical-cavity surface-emitting laserIndium

The invention discloses a sub-wavelength grating and a vertical cavity surface emitting laser. The sub-wavelength grating comprises a substrate layer (2) formed by indium tin oxide; and a grating layer (1) formed by amorphous silicon or aluminum gallium arsenide, wherein the grating layer is formed on the substrate layer (2). The sub-wavelength grating based on the substrate layer (2) formed by indium tin oxide serves as a P-surface reflecting mirror. The vertical cavity surface emitting laser comprises a light emitting device, and the sub-wavelength grating disposed on a P-type doped layer (4) of the light emitting device, wherein the light-emitting device comprises a substrate (8), an N-type doping layer (7) and a supporting table (10) which are sequentially stacked from bottom to top, and a lower electrode (9) is arranged on the bottom surface of the substrate.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

LED chip and preparation method thereof

InactiveCN111081835AEase congestionImprove current distributionSemiconductor devicesCurrent distributionOhmic contact

The invention discloses an LED chip and a preparation method thereof. The LED chip comprises a conductive substrate, an n electrode contact layer, a first insulating layer, a p contact reflector metaland protective layer, annular CBL layers, a p-type GaN layer, an InGaN / GaN multi-quantum well light-emitting layer, an n-type GaN layer and a second insulating layer which are sequentially arranged and distributed from bottom to top. Embedded columnar N electrode layers are respectively inserted into a bonding metal layer and sequentially penetrate through the first insulating layer and the like;and the upper surface of each embedded columnar N electrode layer is connected with the n electrode contact layer to form ohmic contact. According to the LED chip provided by the invention, current distribution optimization can be realized by utilizing the design of the CBL layers around holes under the condition that the number of electrode holes is not increased, namely, the light-emitting areais not lost, and the brightness of the chip is further improved.

Owner:SOUTH CHINA UNIV OF TECH

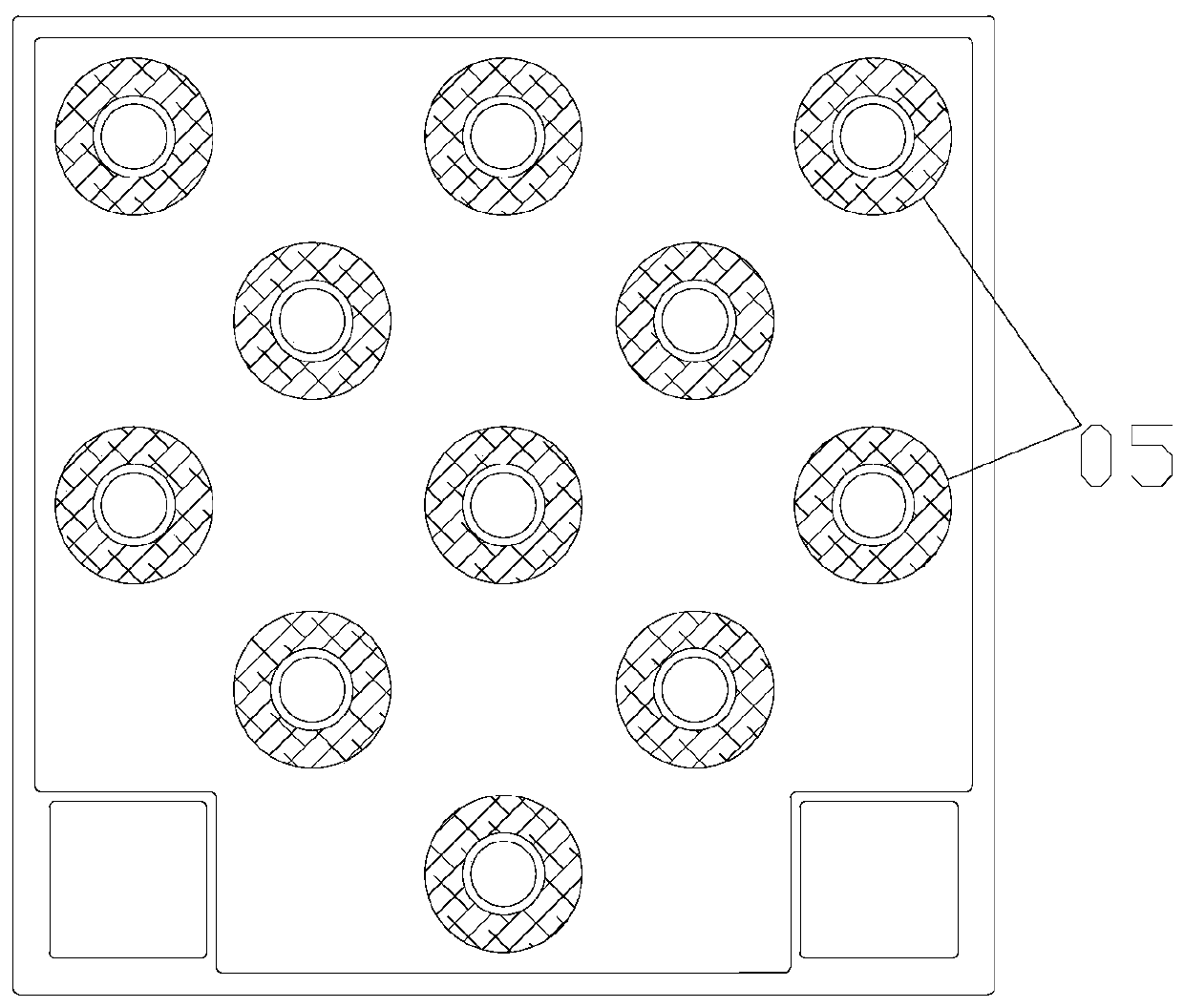

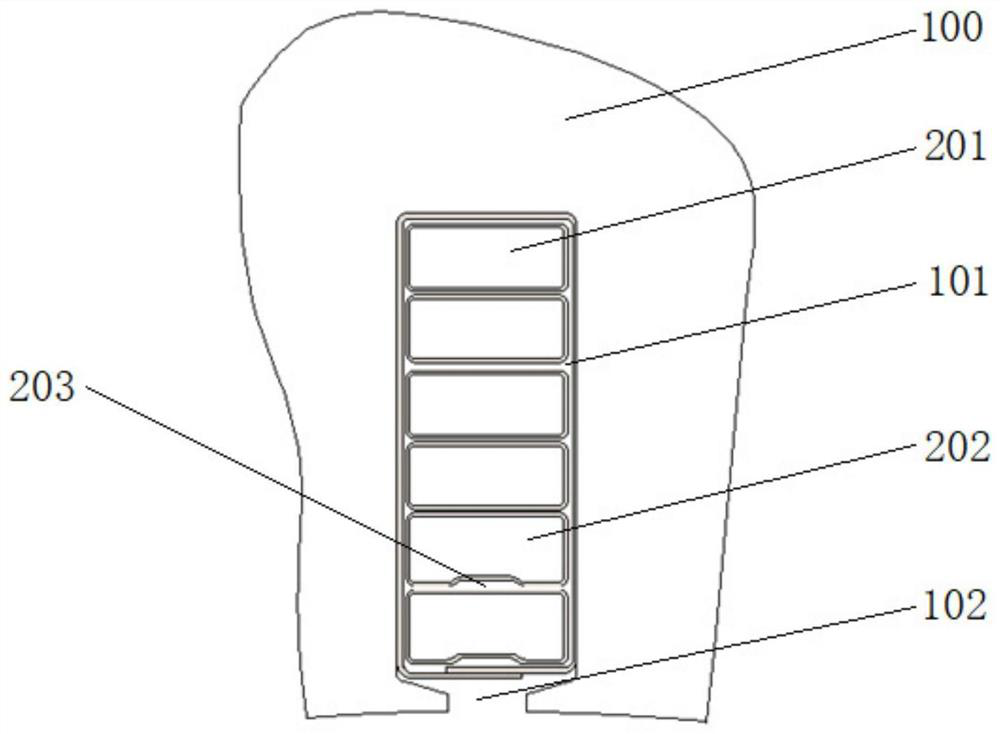

Enameled wire stator with low alternating current loss

PendingCN114337035AImprove the uniformity of current distributionReduce AC lossWindings conductor shape/form/constructionAC - Alternating currentCurrent distribution

The invention discloses an enameled wire stator with low alternating current loss, the inner wall of the stator is provided with a plurality of mounting grooves for placing an enameled wire group, the enameled wire group comprises a plurality of first enameled wires and second enameled wires, the bottom of each second enameled wire is provided with a groove, and each second enameled wire is arranged at one end of a notch of the corresponding mounting groove. The first varnished wire is arranged at one end, away from the notch, of the second varnished wire, the varnished wire with the groove is placed at the notch position of the mounting groove or close to the notch position, and when an armature reacts, due to the fact that the magnetic potential is the strongest, leakage flux linkage in the groove is generated at the notch position most easily at the position close to the notch position. The enameled wire with the groove can effectively improve the current distribution uniformity of the notch wire, thereby achieving the effect of reducing the alternating current loss, and being simple in structure and convenient to use.

Owner:SHANGHAI EVK E-MOTOR TECH CO LTD

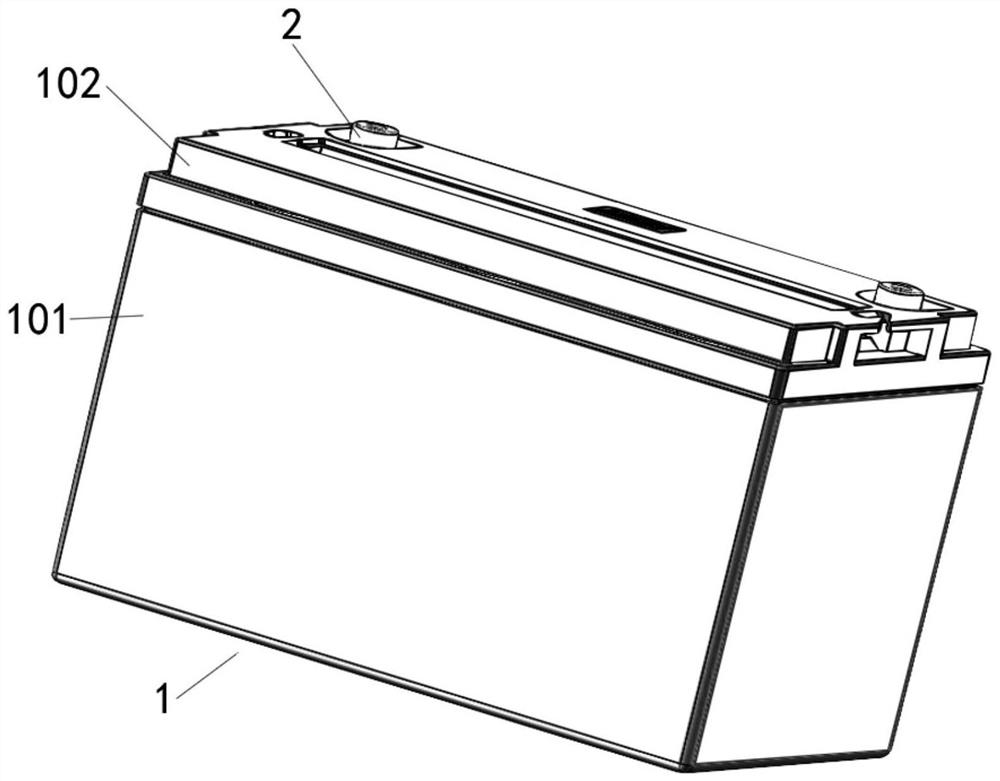

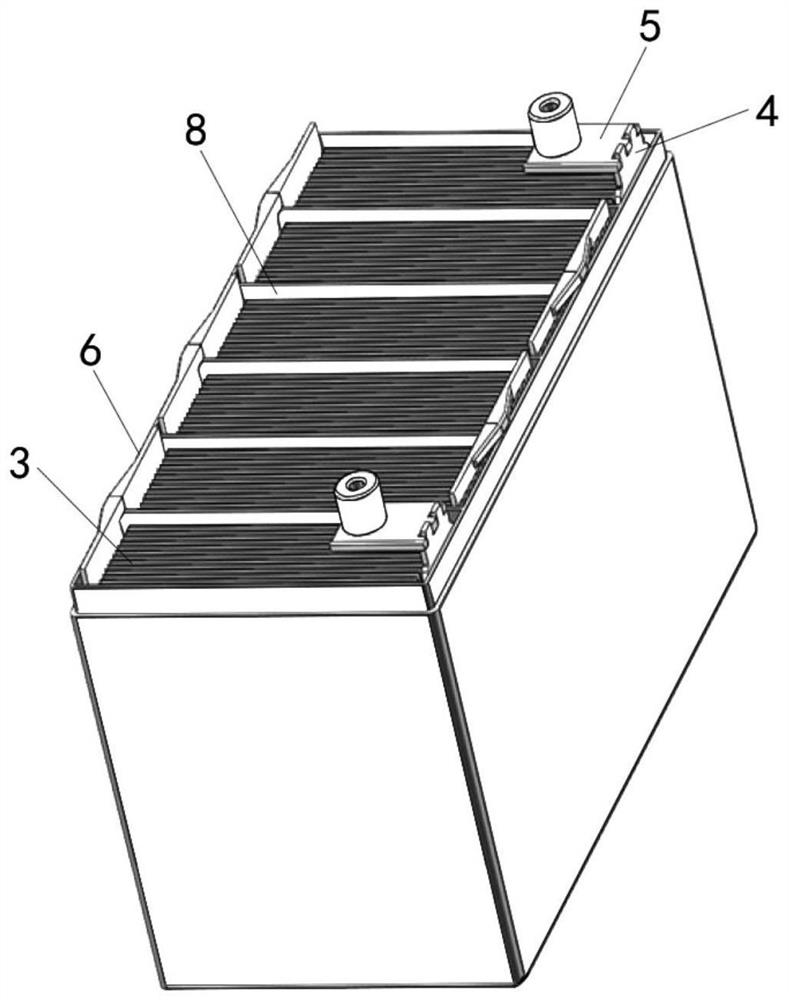

Lead storage battery

PendingCN113839102AImprove the uniformity of current distributionExtended service lifeFinal product manufactureLead-acid accumulators constructionCurrent distributionBusbar

The invention relates to the field of storage batteries, and discloses a lead storage battery, the lead storage battery comprises a shell, series connection assemblies and monomer stage groups, a plurality of monomer stage groups are arranged in parallel in the shell along the horizontal direction, and a plurality of series connection assemblies are arranged on two sides of the monomer stage groups in a staggered manner along the arrangement direction of the monomer stage groups and are used for connecting the plurality of monomer stage groups in series; and the monomer stage groups located at the two ends are connected with output and input terminal assemblies. The lead storage battery is different from a traditional lead storage battery in structure, a plurality of series-connection assemblies are arranged on the two sides of single-body stage groups in a staggered mode and used for connecting the single-body stage groups in series to form a series-connection structure of the single-body stage groups, a transversely-placed structure is formed, and the mode that a traditional vertical type top end outlet tab is connected with a busbar is changed into the mode that the traditional vertical type top end outlet tab and the busbar are transversely place and extend out of the two sides in an opposite mode. According to the structure, the utilization rate of active substances in the monomer grade group is not layered in the service life process, and the current distribution uniformity is high.

Owner:CHAOWEI POWER CO LTD

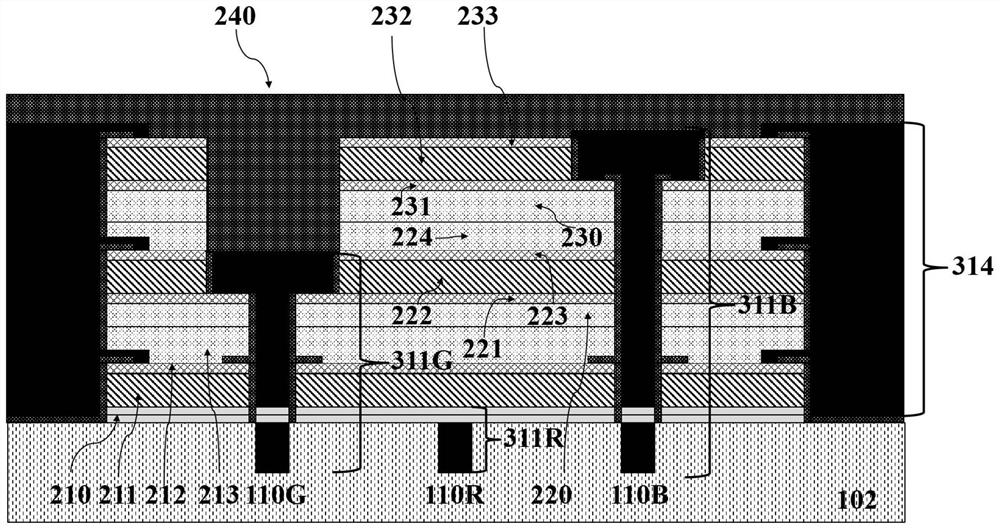

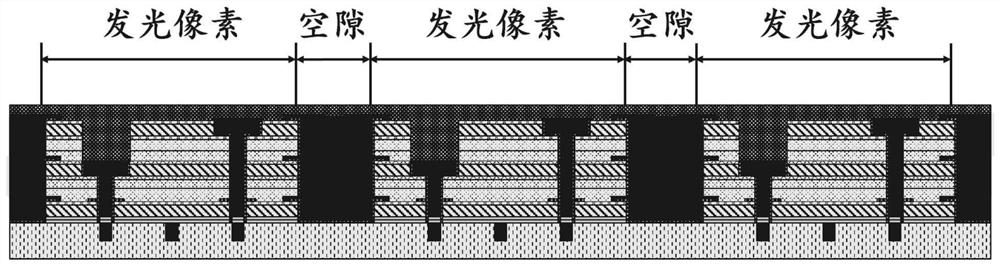

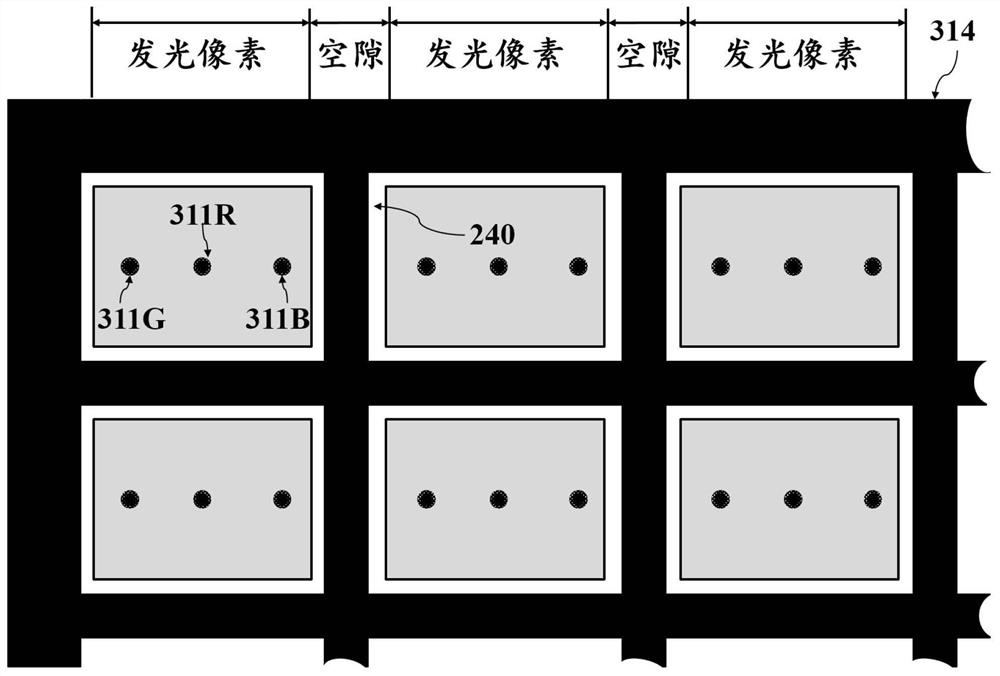

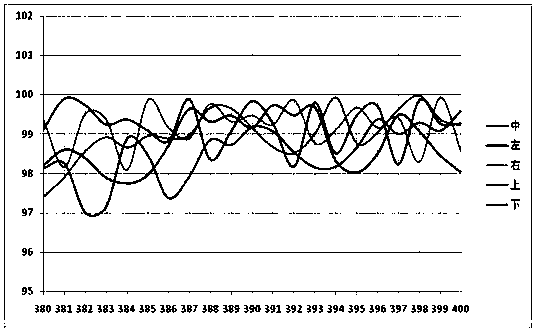

A full-color active addressable micro-led chip structure and manufacturing method thereof

ActiveCN112117356BImprove efficiencyHigh-resolutionSolid-state devicesSemiconductor devicesHemt circuitsMaterials science

The present invention relates to a full-color active addressable Micro-LED chip structure and a manufacturing method thereof, comprising a supporting substrate with a driving circuit array, a stacked layer on the supporting substrate, and a through-stacked layer connected to the driving circuit array Interconnected electrodes, wherein the stacked layers include a substrate metal bonding layer, a multi-layer sandwich structure covered with a transparent conductive layer on the upper and lower surfaces of the multicolor light-emitting epitaxial layer, a dielectric filling layer, a filter layer, a passivation layer, and interconnected electrodes from bottom to top. It includes an array electrode connecting the p-type surface of the first epitaxial layer and the driving pixel, a penetrating array electrode connecting the p-type surface of the second epitaxial layer and the driving pixel, a penetrating array electrode connecting the p-type surface of the third epitaxial layer and the driving pixel, and a penetrating array electrode connecting the p-type surface of the third epitaxial layer and the driving pixel. The stacked layers are respectively connected to the common electrode of the n-type surface of the multi-color light-emitting epitaxial layer. The technical solution of the present invention can manufacture high-resolution and high-efficiency full-color drive fusion Micro-LED chips.

Owner:XIAMEN UNIV

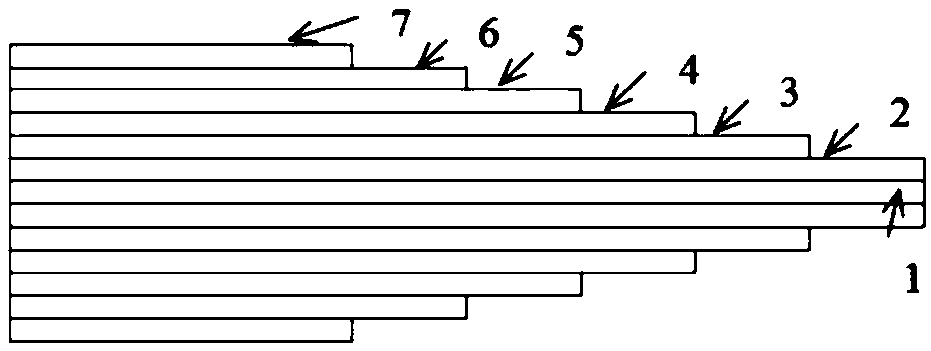

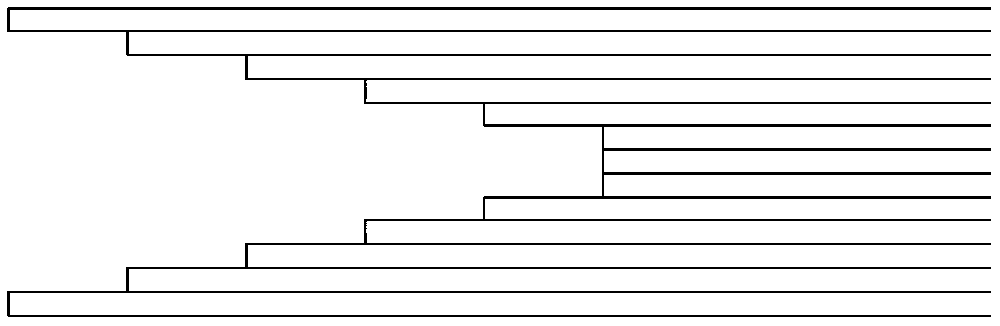

A kind of LED chip with ultra-high reflectivity ultraviolet through-hole structure and preparation method thereof

ActiveCN108447958BImprove reflectivityImprove antioxidant capacitySemiconductor devicesUltravioletHigh reflectivity

The invention discloses an ultrahigh reflectivity LED chip in an ultraviolet through-hole structure. The LED chip comprises an epitaxial substrate and a LED epitaxial wafer grown on the epitaxial substrate. The LED epitaxial wafer comprises an n-type doped GaN film, an InGaN or AlGaN / GaN multiple quantum well, and a p-type doped GaN film. The InGaN or AlGaN / GaN multiple quantum well is grown on the n-type doped GaN film. The p-type doped GaN film is grown on the InGaN / GaN quantum well. The epitaxial substrate is a Si substrate, a GaN substrate, a Cu substrate, a LSAT substrate, or a LiGaO2 substrate. The invention also provides a manufacturing method for the ultrahigh reflectivity LED chip in an ultraviolet through-hole structure. The LED chip has characteristics of high reflectivity in anultraviolet band and strong oxidation resistance while perfectly inheriting advantages of a vertical linear structure.

Owner:HEYUAN CHOICORE PHOTOELECTRIC TECH CO LTD

Light-emitting diode, light-emitting module and light-emitting device

ActiveCN114023858ASolve uneven lightingAvoid exceptionSolid-state devicesSemiconductor devicesCurrent distributionEngineering

The invention relates to the technical field of light-emitting diode manufacturing, in particular to a light-emitting diode, a light-emitting module and a light-emitting device. The second contact electrode of the light-emitting diode is provided with two special parts with non-linear extension parts, so that an ejector pin operation window is expanded, and the problem that a chip is abnormal due to the fact that the ejector pin bursts a convex area of the contact electrode and is prone to bursting is solved as much as possible, and the problem of non-uniform light emitting of the light emitting diode caused by current change due to position change of the contact electrode can also be solved to a certain extent. Meanwhile, under the condition that the shape of the second contact electrode is guaranteed and the current distribution uniformity is improved, a current blocking layer below the extension part of the second contact electrode can be canceled, so that the voltage is reduced under the condition that the brightness is not obviously influenced, and the normal photoelectric performance of the filament lamp and the lamp strip is effectively maintained.

Owner:XIAMEN SANAN OPTOELECTRONICS CO LTD

An aluminum alloy high-voltage cable aluminum-copper composite terminal

ActiveCN108615985BImprove the strength of the connection structureImprove impact resistanceElectric connection structural associationsMetal/alloy conductorsHigh pressureElectric power

The invention discloses an aluminum-copper composite wiring terminal for an aluminum alloy high voltage cable, which comprises a copper alloy base body and wiring slots located at two ends of the copper alloy base body, wherein the connecting slots are of a U-shaped slot structure in cross section and symmetrically distributed about an axis of the copper alloy base body, the length of the connecting slots is 1 / 5-1 / 2 of the length of the copper alloy base body, the inner surface of each wiring slot is uniformly provided with an aluminum alloy lining, and the thickness of the aluminum alloy lining is 1 / 4-3 / 4 of the thickness of the side wall of the wiring slot. The preparation method comprises four steps such as copper alloy base body prefabrication, wiring slot preprocessing, aluminum lining positioning and wiring slot diameter expansion and wiring slot fine machining. On the one hand, the connecting structure strength, impact resistance, corrosion resistance and high temperature resistance between the wiring terminal and the cable can be effectively improved, and the mechanical structural strength of the wiring terminal is greatly improved; and on the other hand, the overload capacity of the wiring terminal can be effectively improved, the uniformity of current distribution is improved, so that the reliability and operation stability of power cable connection are greatly improved.

Owner:上海永固电力器材有限公司

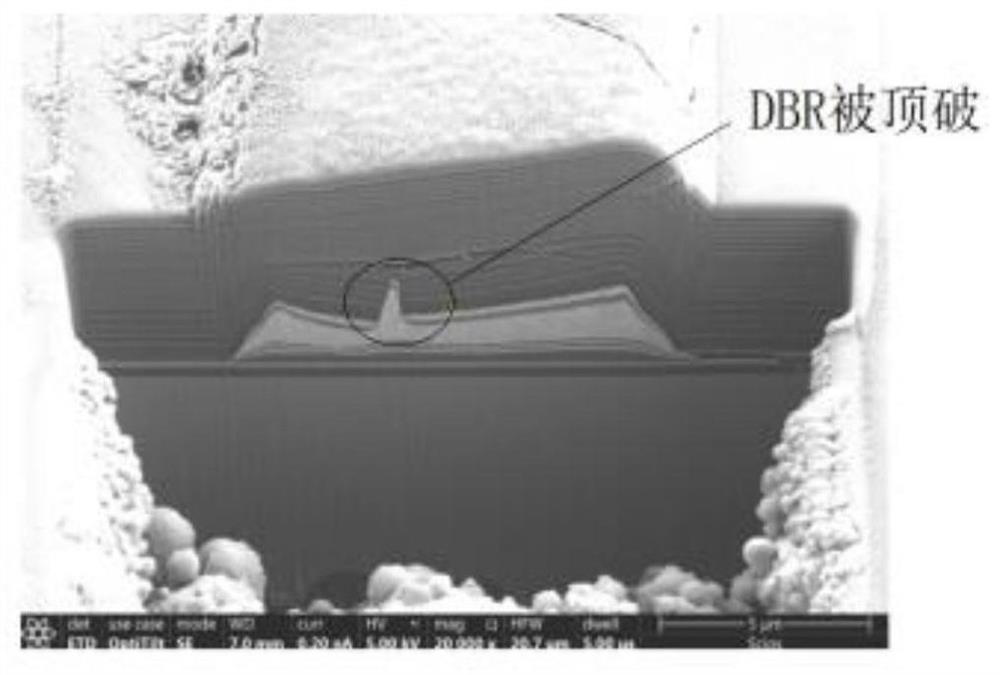

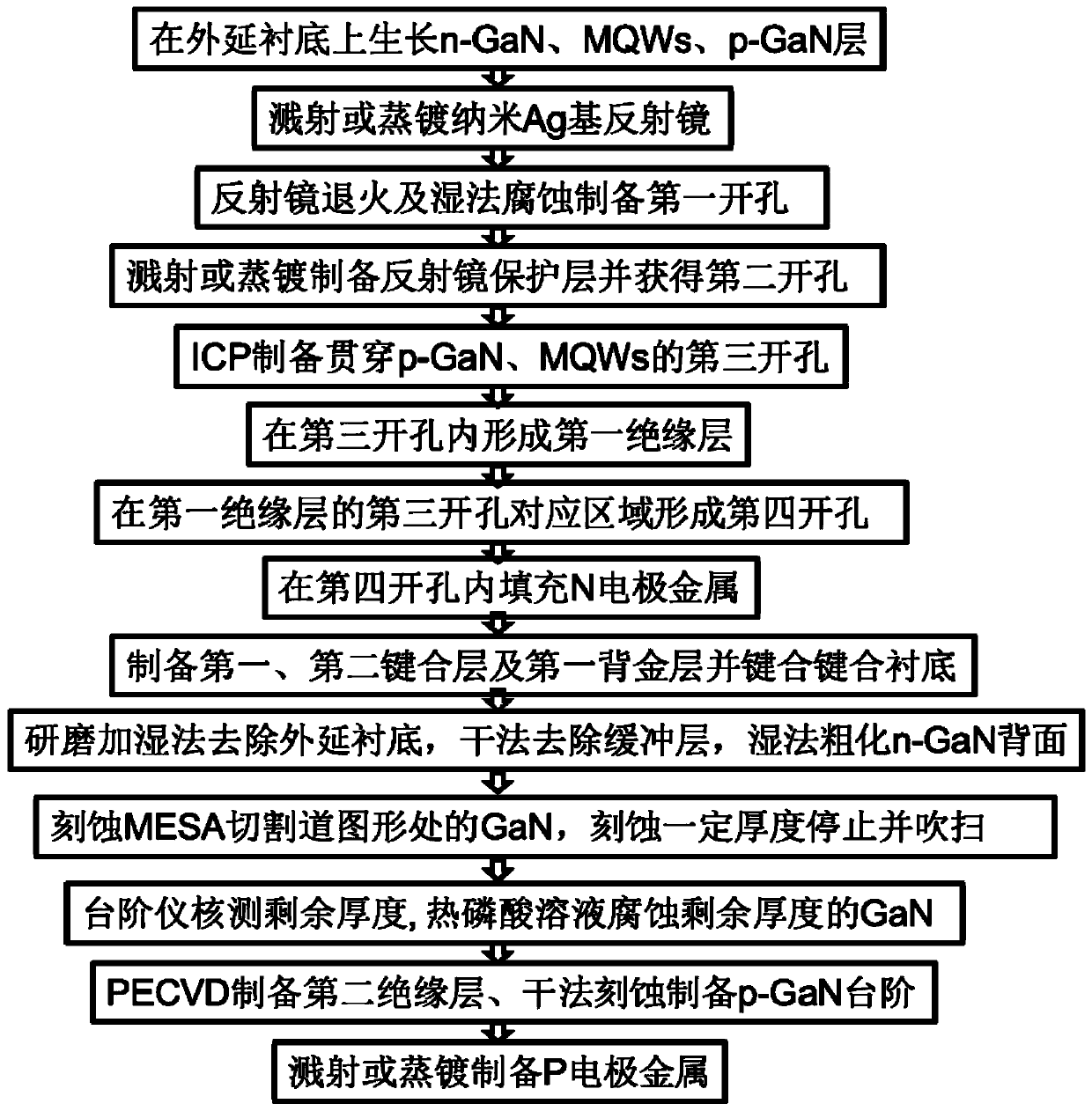

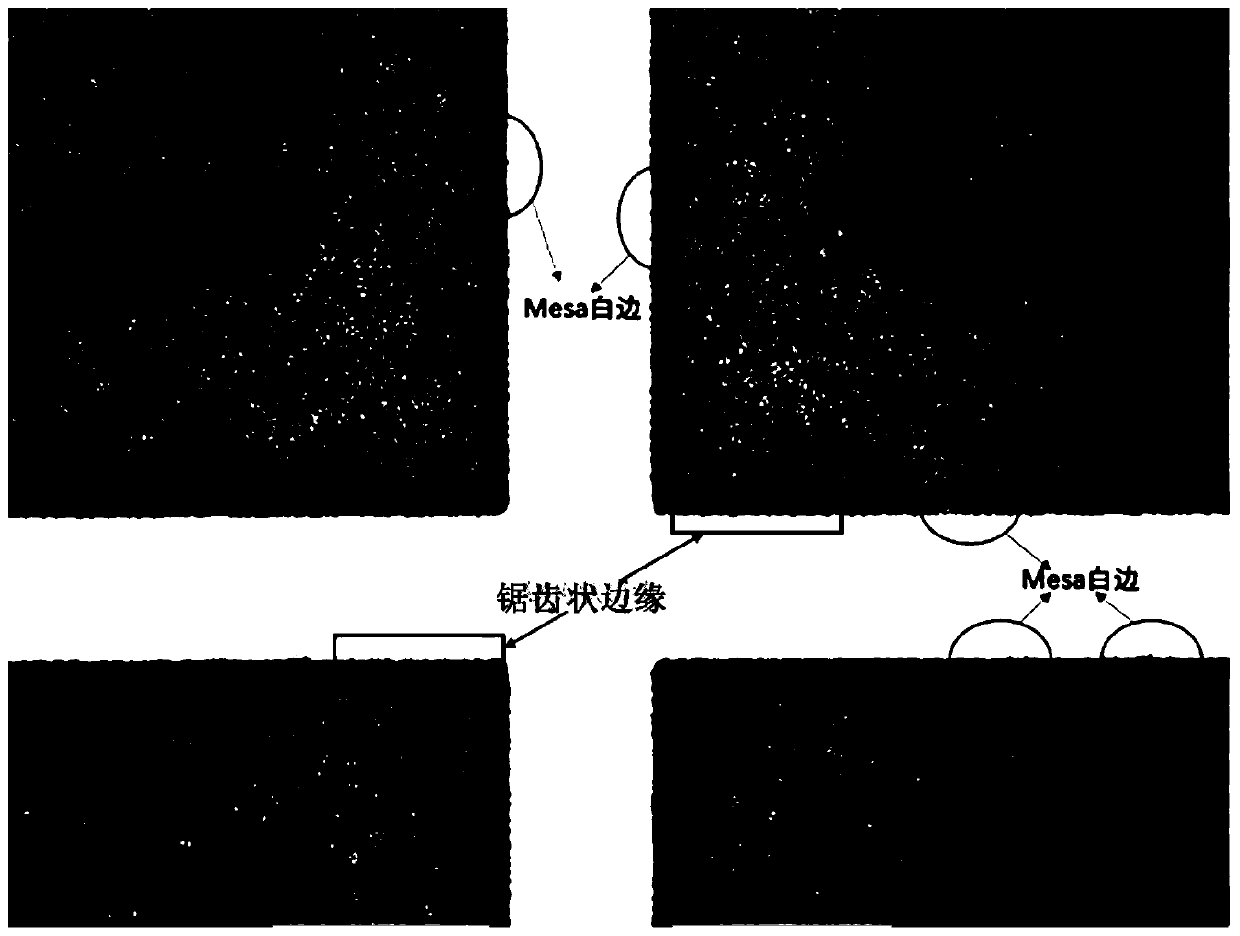

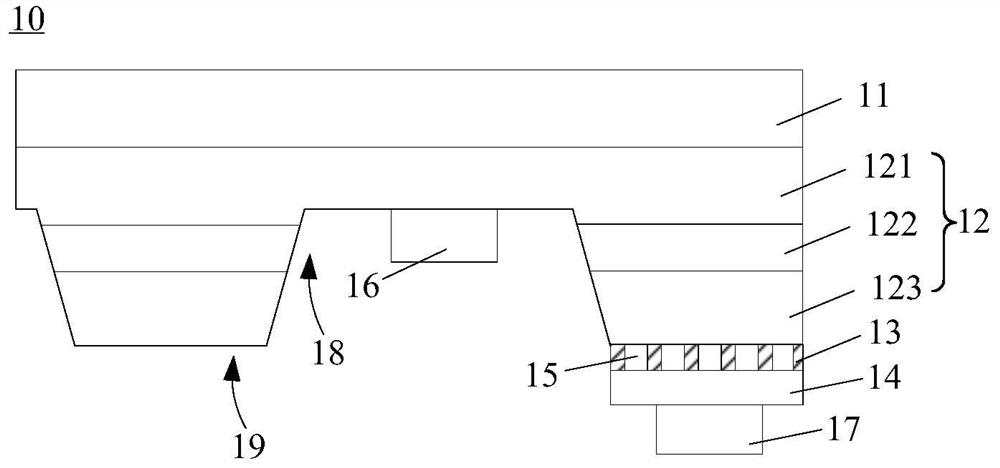

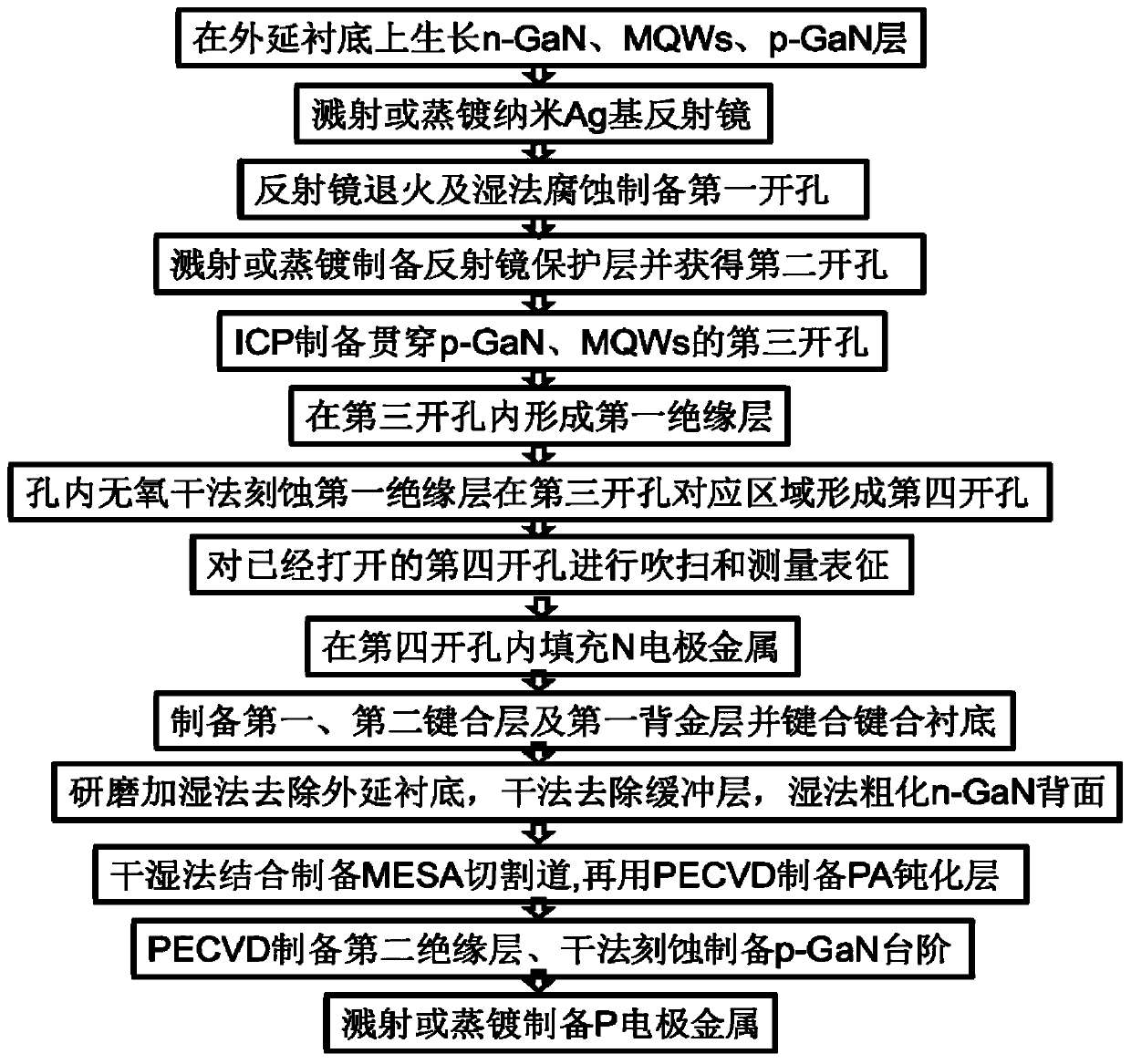

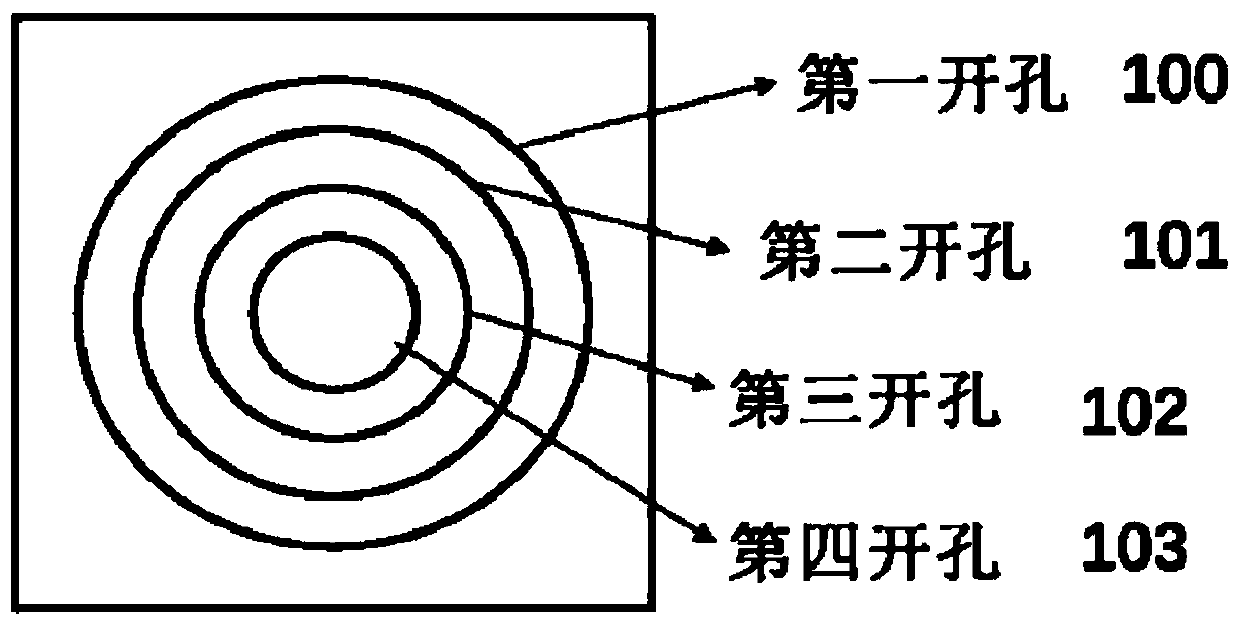

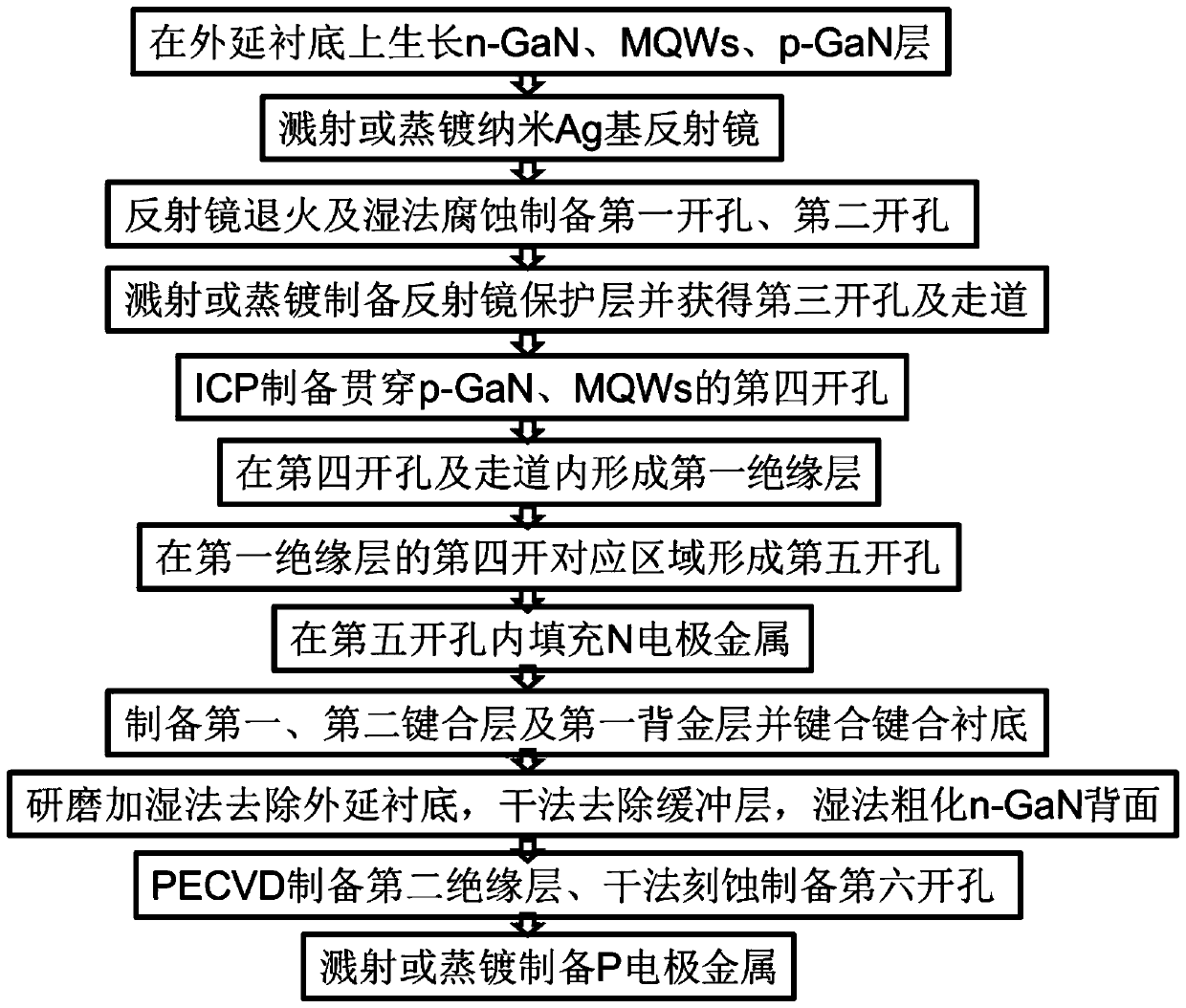

A kind of non-leakage Mesa scribe line 3D through-hole superstructure LED chip and preparation method thereof

ActiveCN108389952BOvercome the disadvantage of climbing up to the MESA sidewallSolve the leakSemiconductor devicesEngineeringMetal electrodes

The invention discloses an electric-leakage-free LED chip of a 3D through hole superstructure with an MESA cutting channel and a preparation method of the LED chip. The preparation method comprises that an n type doped GaN layer, an InGaN / GaN multi-quantum well layer and a p type doped GaN layer are prepared on an epitaxial substrate, a nanometer Ag-based reflector is prepared in the surface of anLED epitaxial wafer, and a reflector protective layer, MESA holes and an insulating layer are prepared; N metal electrodes and bonding layer metal are filled into the holes; an LED epitaxial layer istransferred to position on a Si substrate; the MESA cutting channel is prepared in a dry and wet combined method; and a passivation layer PA, a P electrode pattern and P electrode metal are preparedto form the LED chip. The thickness ratio etching the MESA cutting channel in the dry and wet method is optimized, the obtained GaN MESA cutting channel is tidy in edge, free of penetration of a corrosion liquid, free of white edges, free of climbing and backwash of the metal sidewall, and stable and easy control in technology, and the problem of electric leakage of the LED chip is solved.

Owner:SOUTH CHINA UNIV OF TECH

A method of manufacturing a light-emitting diode

InactiveCN104681672BReduce current congestionImprove light extraction efficiencySemiconductor devicesCurrent distributionEngineering

The invention provides a method for manufacturing a light-emitting diode, comprising steps: 1) forming a light-emitting epitaxial structure on the surface of a growth substrate; 2) simultaneously etching an N-electrode platform and a plurality of holes in each light-emitting unit, and the plurality of holes Located between the N electrode platform and the P electrode; 3) Tangentially forming multiple cutting grooves; 4) Depositing a SiO2 layer and removing the SiO2 layer in each hole; 5) Using chemical etching to etch out multiple holes at the bottom of each hole dislocation pits, and remove the residues in each cutting groove at the same time; 6) form the SiO2 layer again; 7) remove part of the SiO2 layer, retain the bottom and side walls of each hole, and the SiO2 layer under the P electrode ; 8) forming a current spreading layer; 9) preparing a P electrode and an N electrode. The invention can reduce the current congestion of the light-emitting diode, improve the uniformity of current distribution, and improve the light-emitting efficiency of the light-emitting diode by making a plurality of holes between the P electrode and the N electrode and forming dislocation pits at the bottom of the holes.

Owner:EPILIGHT TECH

Preparation method of aluminum-copper composite terminal for aluminum alloy high-voltage cable

ActiveCN108493735BImprove the strength of the connection structureImprove impact resistanceContact member manufacturingMetal/alloy conductorsTemperature resistanceHigh pressure

The invention discloses an aluminum alloy high-voltage cable aluminum copper composite terminal. The aluminum alloy high-voltage cable aluminum copper composite terminal comprises a copper alloy substrate and connecting grooves formed in the two ends of the copper alloy substrate; the connecting grooves adopt a U-shaped groove-shaped cross section and are symmetrically distributed along the axis of the copper alloy substrate; the length of the connecting grooves is 1 / 5-1 / 2 of that of the copper alloy substrate; the inner surfaces of the connecting grooves are both distribute with aluminium alloy lining layers; and the thickness of the aluminium alloy lining layers is 1 / 4-3 / 4 of that of the connecting groove side wall; and the preparation method comprises four steps of copper alloy substrate prefabrication, connecting groove pre-processing, aluminum lining layer positioning, connecting groove diameter expansion and connecting groove fine processing. By virtue of the aluminum alloy high-voltage cable aluminum copper composite terminal and the preparation method thereof, the connecting structural strength, the impact resistance performance, the corrosion resistance performance and thehigh temperature resistance performance between the terminal and the cable can be improved effectively, so that the mechanical structural strength of the terminal is highly improved; and in addition,the overload capacity of the terminal is improved effectively, and current distribution uniformity is improved, thereby highly improving reliability and operational stability of the power cable connection operation.

Owner:江西杰洋科技有限公司

a semiconductor device

ActiveCN104425447BSpeed up fusingFuse completelySemiconductor/solid-state device detailsSolid-state devicesElectric fusesNeck parts

The invention provides a semiconductor device which comprises an electric fuse positioned on the surface of a semiconductor substrate, and a first conductive plug and a second conductive plug which are respectively positioned on a positive electrode and a negative electrode of the electric fuse, wherein each of the first conductive plug and the second conductive plug comprises an end part and a neck part; the end parts are arranged in a manner of being close to a middle section, and the neck parts are arranged in a manner of being far away from the middle section; the widths of the first conductive plug and the second conductive plug in the direction perpendicular to the middle section of the electric fuse are greater than the widths of the neck parts. After voltage is applied to the first conductive plug and the second conductive plug, current is concentrated to the end parts, and heat generated on the first conductive plug and the second conductive plug is concentrated to the end parts, so that the fusing rate of the middle section of the electric fuse is increased.

Owner:SEMICON MFG INT (SHANGHAI) CORP

An LED chip with an ultraviolet through-hole structure of a multifunctional reflector and a preparation method thereof

ActiveCN108649107BImprove thermal stabilityAccelerated corrosionSemiconductor devicesUltravioletMaterials science

The invention discloses a multifunctional reflector ultraviolet through hole structure LED chip, comprising an epitaxial substrate and an LED epitaxial wafer subjected to epitaxial growth on the epitaxial substrate, wherein the LED epitaxial wafer comprises an n-type doped GaN film, InGaN / GaN multiple quantum wells and a p-type doped GaN film; the n-type doped GaN film grows on the epitaxial substrate; the InGaN / GaN multiple quantum wells grow on the n-type doped GaN film; the p-type doped GaN film grows on the InGaN / GaN multiple quantum wells; the epitaxial substrate is a Si substrate, a GaNsubstrate, a sapphire substrate, a LSAT substrate or LiGaO2 substrate. The invention also provides a preparation method of the multifunctional reflector ultraviolet through hole structure LED chip. Areflector protection layer on the LED chip has excellent thermal stability, high-temperature oxidation resistance and phosphoric acid corrosion resistance, and has three functions of a reflector, a reflector protection layer and an isolation layer.

Owner:HEYUAN CHOICORE PHOTOELECTRIC TECH CO LTD

High conductivity grid structure and processing method of lead-acid battery

ActiveCN107768682BImprove conductivityGuaranteed cycle lifeElectrode carriers/collectorsAcid corrosionStructural engineering

Owner:CHAOWEI POWER CO LTD

A crimping type cable conductor joint with current equalizing function and preparation method thereof

ActiveCN107611627BReduce skin effectReduce AC resistanceLine/current collector detailsConnections effected by permanent deformationElectrical resistance and conductanceElectrical conductor

The invention belongs to the fields of a power transmission line and a power cable, and particularly relates to a crimping type cable conductor connector with a current sharing effect and a preparation method. Each layered insulating conductor consists of a first cylinder positioned in the centre of the conductor, and a second cylinder and a third cylinder with hollow-out central parts and arranged outside the first cylinder in a sleeving manner; the layered insulating conductor is inserted into a hollow conductor connecting pipe from the two ends of the conductor connecting pipe; in a crimping process, a crimping die surrounds the upper and lower sides of a crimping section of the conductor connecting pipe; and the cable conductor connector is extruded by die closing of the crimping die,and the conductor connecting pipe and the layered insulating conductor are subjected to micro deformation. By virtue of the crimping type cable conductor connector, the alternating current resistanceof the large-section cable conductor with the layered insulating structure in the conductor connector position can be lowered, so that the problem of temperature rise in the conductor and the connector positions when the large-section layered insulating conductor is applied can be overcome.

Owner:STATE GRID CORP OF CHINA +3

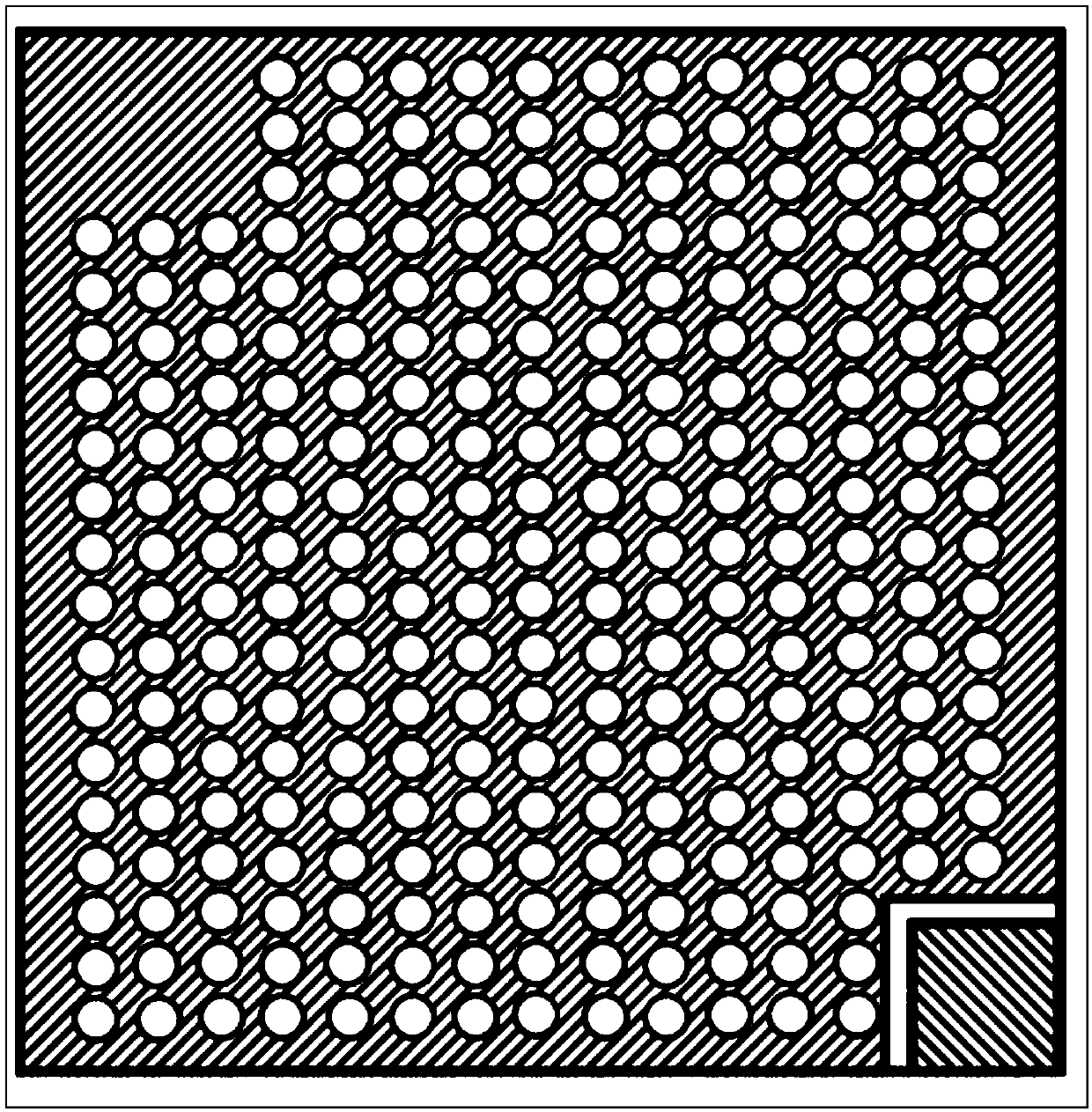

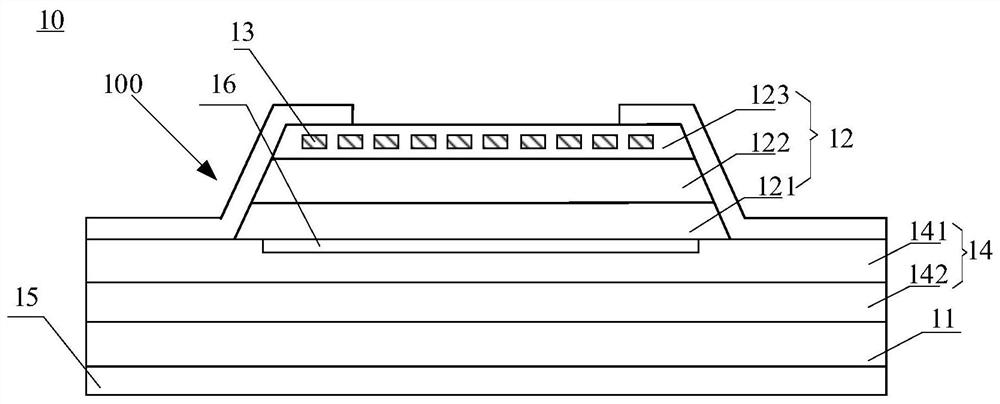

Light-emitting diode and manufacturing method thereof

ActiveCN112652689AImproved current distributionImprove the uniformity of current distributionSemiconductor devicesOhmic contactSemiconductor

The invention relates to the field of light emitting diodes, and particularly discloses a light emitting diode and a manufacturing method thereof. The light emitting diode comprises: a substrate; a light-emitting epitaxial layer comprising a first semiconductor layer, an active light-emitting layer and a second semiconductor layer which are sequentially stacked on one side of the substrate; a plurality of ohmic contact patterns arranged on one side, deviating from the active light-emitting layer, of the first semiconductor layer or the second semiconductor layer at intervals in a dot matrix mode; and a reflector layer positioned on one side, deviating from the active light-emitting layer, of the plurality of ohmic contact patterns and covering the plurality of ohmic contact patterns and the first semiconductor layer or the second semiconductor layer between the plurality of ohmic contact patterns. By means of the mode, current distribution can be effectively improved, the current distribution uniformity is improved, the efficiency sudden drop effect under large current is restrained, and the reflectivity of the reflector is improved.

Owner:SHENZHEN INST OF WIDE BANDGAP SEMICON

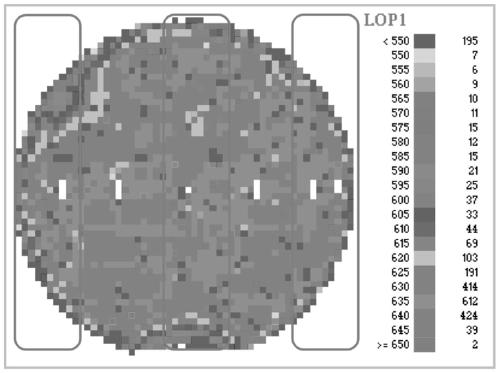

A method for reducing the voltage of a 3D through-hole superstructure LED chip by anaerobic dry etching in a hole

ActiveCN108389955BReduce voltageSolve problems affecting the lift-off processSemiconductor devicesMetallic electrodeEngineering

The invention discloses an in-hole oxygen-free dry etching method for reducing the voltage of an LED chip of a 3D through hole superstructure. The method comprises that an n type doped GaN layer, an InGaN / GaN multi-quantum well layer and a p type doped GaN layer are prepared on an epitaxial substrate. A nanometer Ag-based reflector, reflector protective layer, N MESA holes and an insulating layerare prepared in the surface of an LED epitaxial wafer, and n-pad circular holes are formed; SiO2 in the n-pad circular holes are etched in an oxygen-free drying method, the holes are filled with N metal electrodes, and bonding layer metal is prepared; and an old growth substrate is peeled, an MESA cutting channel, a passivation layer PA, a P electrode pattern and P electrode metal are prepared toform the LED chip. The etching ratio of SiO2 to photoresist is controlled to solve the problem that the voltage of the LED chip of the 3D through hole superstructure is too high. The yield rate of thedriving voltage of the whole LED wafer is improved greatly, and the average of in-wafer voltage can be reduce to a value lower than 3.0V.

Owner:SOUTH CHINA UNIV OF TECH

led device structure

InactiveCN103682022BAvoid concentrationAdjust current distributionSemiconductor devicesPower flowSemiconductor materials

The invention provides an LED device structure. The LED device structure sequentially comprises a semiconductor substrate, a P-type semiconductor layer, a luminous layer and an N-type semiconductor material layer, wherein a part of the N-type semiconductor material layer exposes. A P-electrode and an N-electrode which are separated are respectively formed on the P-type semiconductor material layer and the N-type semiconductor material layer and respectively comprise an insulating layer, a transparent conductive layer and a metal layer, wherein the metal layer comprises the P-block-shaped metal electrode portion and P-linear metal electrode portion which are connected mutually and a N-block-shaped metal electrode portion and N-linear metal electrode portion which are connected mutually. The N-block-shaped metal electrode portion extends towards the direction of the P-block-shaped metal electrode portion from the N-linear metal electrode portion, and the insulating layer of the N-electrode is located right under the N-linear metal electrode portion. By arranging the insulating layer right under the N-linear metal electrode portion, the distribution uniformity of current in an N-type GaN layer is improved, and the brightness of an LED device is further improved.

Owner:EPILIGHT TECH

A welded cable conductor joint with current equalizing function and its welding method

ActiveCN107579356BReduce skin effectReduce AC resistanceLine/current collector detailsSoldered/welded conductive connectionsElectrical resistance and conductanceElectrical conductor

The invention belongs to the power transmission line power cable field and particularly relates to a welding type cable conductor connector having the current sharing effect and a welding method. Thetotal layer quantity of conductors is N, when M layers of internal conductors are welded, low resistivity welding rods A are utilized, when O layers of middle conductors are welded, low resistivity welding rods A are utilized, when (N-M-O) layers of external conductors are welded, high resistivity welding rods B are utilized. The method is advantaged in that a problem of temperature rising of theconductors and connector points during application of large-cross section layered insulation conductors can be solved. On the condition that the layered energy saving and consumption reduction conductor performs the effective AC resistance reduction effect, disadvantages of relatively large AC resistance and relatively high temperature existing in a traditional crimping type cable conductor connector under long-term rated work conditions are ameliorated, the process is simple, field maneuverability is strong, line operation loss of the large-cross section AC power cable can be reduced, power transmission efficiency is improved, and the excellent energy saving and consumption reduction effect is realized.

Owner:STATE GRID CORP OF CHINA +3

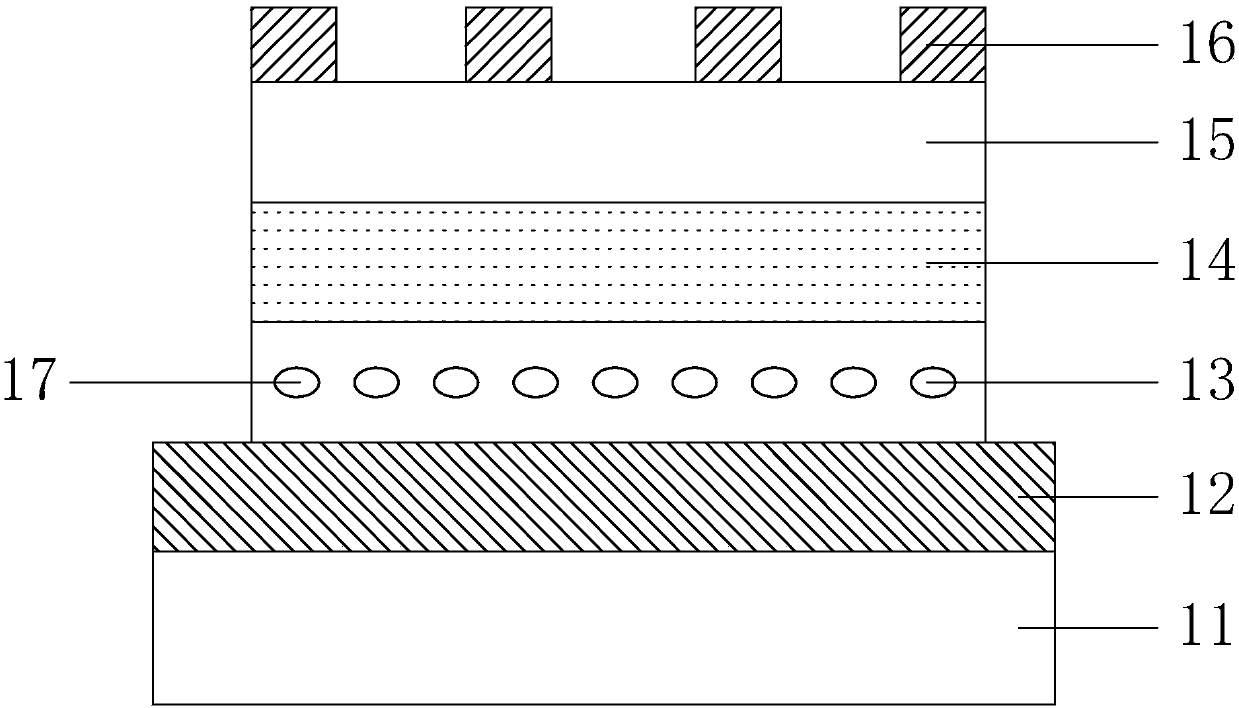

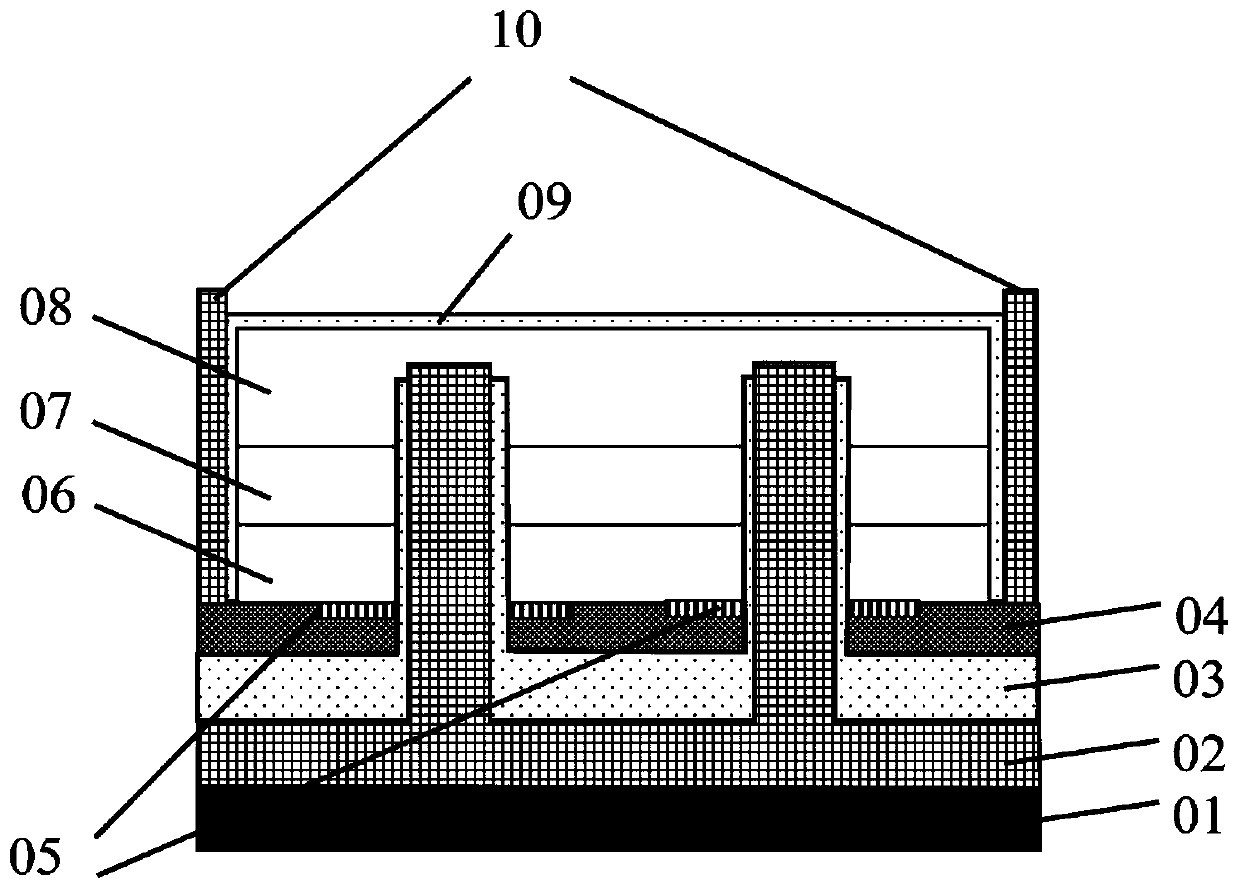

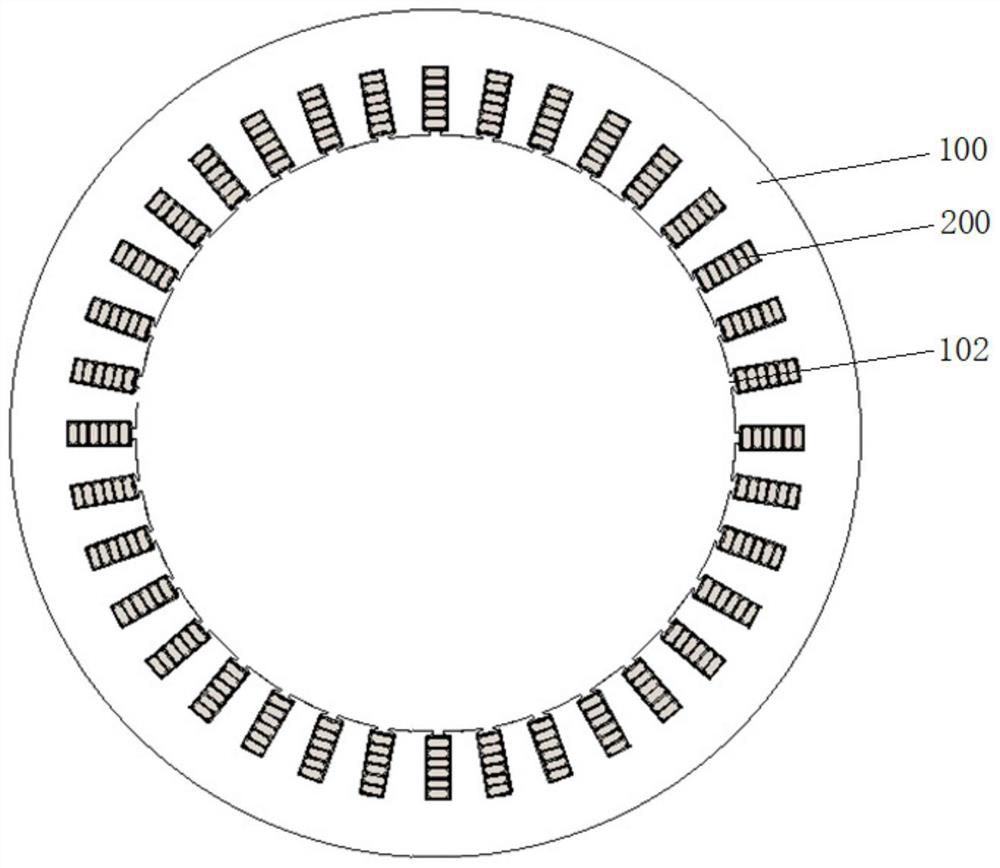

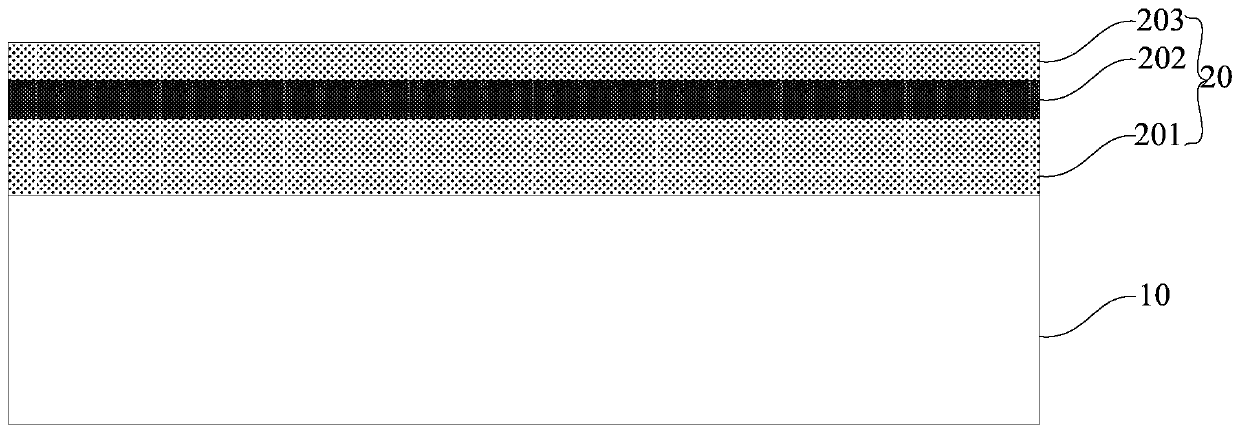

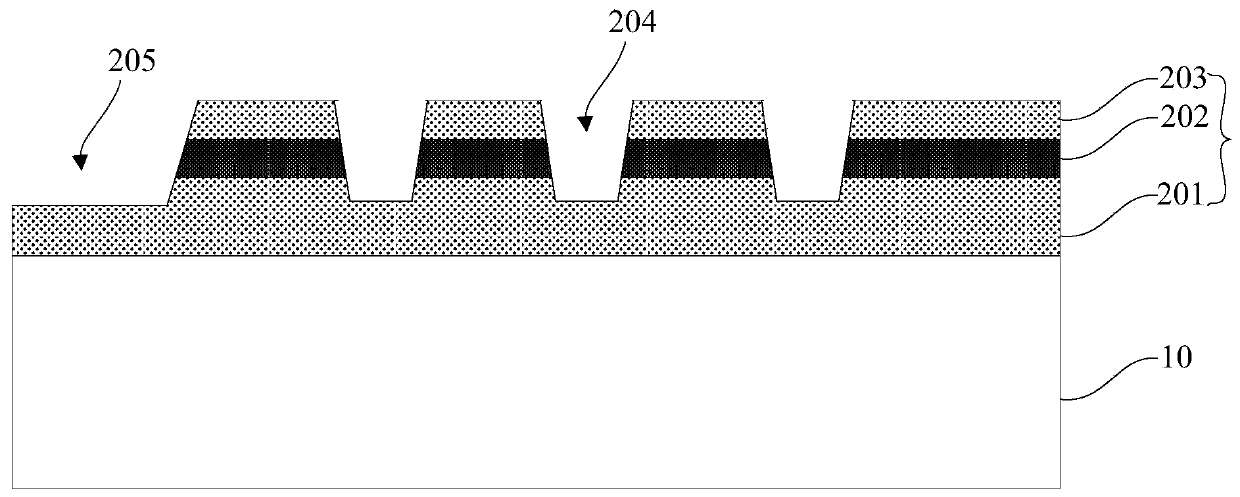

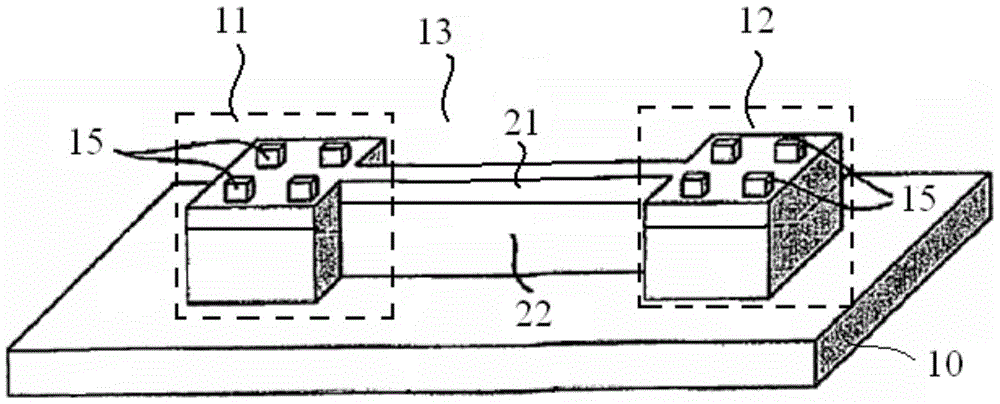

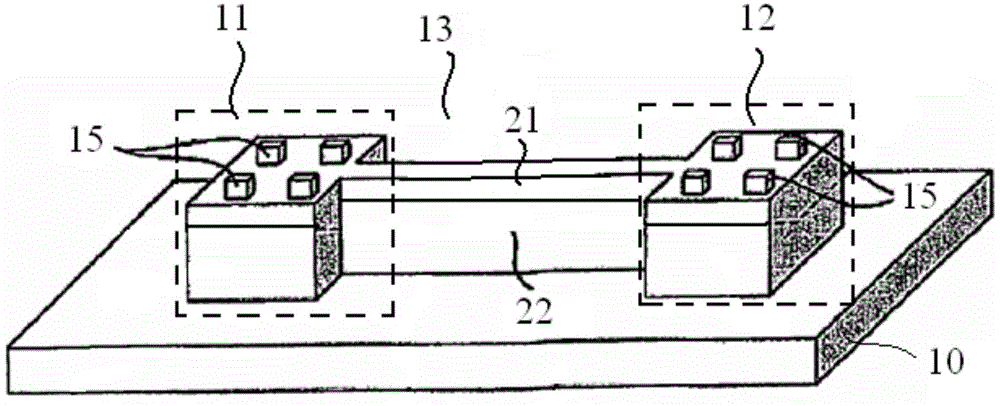

A kind of 3D through-hole superstructure LED chip and preparation method thereof

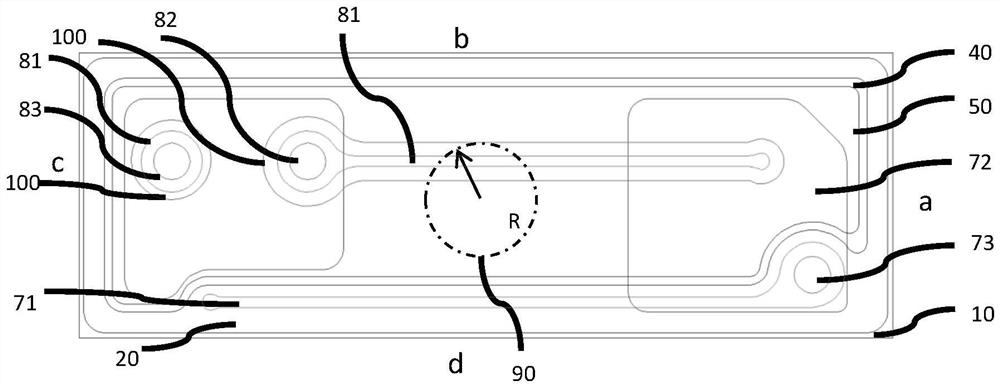

ActiveCN108365078BImprove the uniformity of current distributionHigh light efficiencySemiconductor devicesPower flowCurrent distribution

The invention discloses a silicon-based 3D through-hole super-structure LED chip and a preparation method thereof. The preparation method comprises that an n-GaN layer, an InGaN / GaN multi-quantum welllayer and a p-GaN layer are grown on an epitaxial substrate successively, a reflector layer and a reflector protection layer are prepared, holes are formed, an insulating layer is prepared, and N electrode metal filling the holes and bonding-layer metal are prepared; a growth substrate is peeled, an MESA channel and a PA layer are prepared, and P electrode metal is prepared; and the complete silicon-based LED chip with the vertical 3D hole structure is prepared. The 3D through hole super structure has advantages of a vertical linear structure, and converts a 2D current expansion capability ofthe linear structure into a 3D current expansion capability, the current distribution uniformity is greatly improved, and the luminous efficiency is improved greatly.

Owner:HEYUAN CHOICORE PHOTOELECTRIC TECH CO LTD

Semiconductor device

ActiveCN104425447ASpeed up fusingFuse completelySemiconductor/solid-state device detailsSolid-state devicesPower semiconductor devicePower flow

The invention provides a semiconductor device which comprises an electric fuse positioned on the surface of a semiconductor substrate, and a first conductive plug and a second conductive plug which are respectively positioned on a positive electrode and a negative electrode of the electric fuse, wherein each of the first conductive plug and the second conductive plug comprises an end part and a neck part; the end parts are arranged in a manner of being close to a middle section, and the neck parts are arranged in a manner of being far away from the middle section; the widths of the first conductive plug and the second conductive plug in the direction perpendicular to the middle section of the electric fuse are greater than the widths of the neck parts. After voltage is applied to the first conductive plug and the second conductive plug, current is concentrated to the end parts, and heat generated on the first conductive plug and the second conductive plug is concentrated to the end parts, so that the fusing rate of the middle section of the electric fuse is increased.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com