Epitaxial growth method for improving current expansion capability of nitride LED

A technology of epitaxial growth and current expansion, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of reducing the luminous efficiency of LED devices, antistatic ability and service life, unsatisfactory current expansion effect, and low LED luminous efficiency. Achieve the effects of improving current expansion, improving the uniformity of current distribution, and ensuring the quality of epitaxial crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

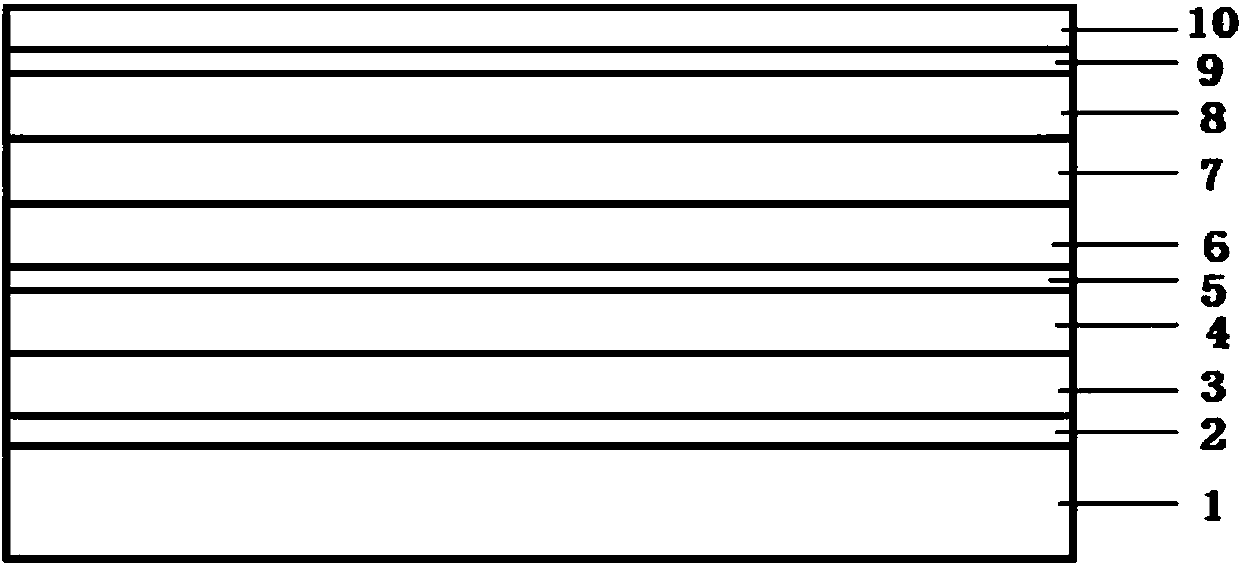

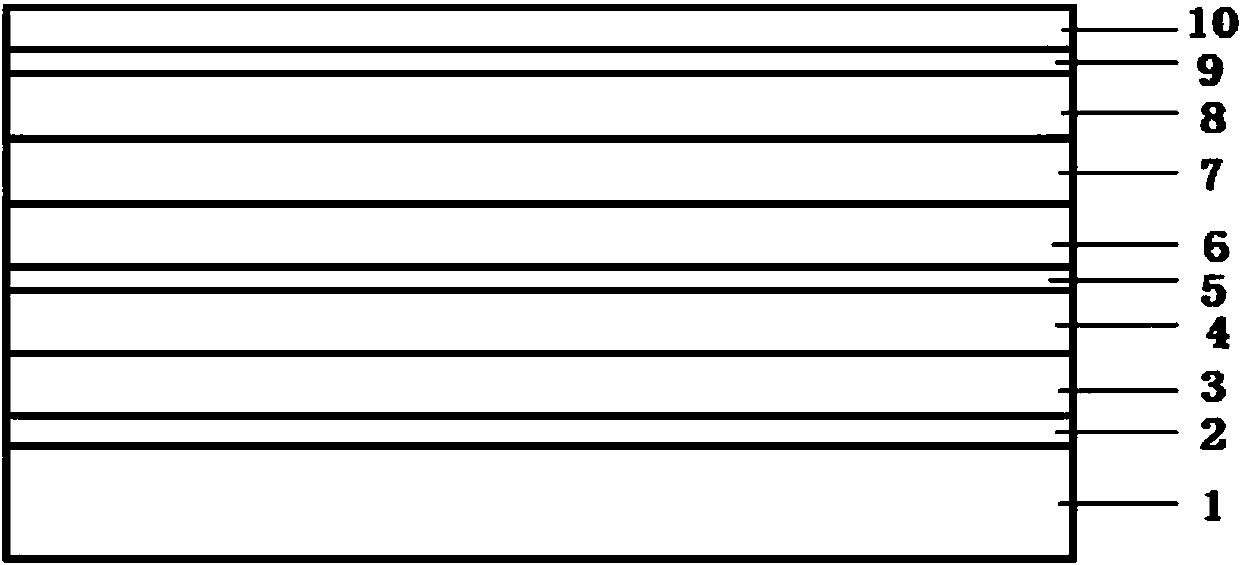

[0043] An epitaxial growth method for improving the current spreading ability of a nitride LED, including the process of growing a graphene layer, specifically:

[0044] Step 1, processing the substrate 1;

[0045] Step 2, growing a low-temperature nitride buffer layer 2 on the substrate 1 and forming irregular small islands on the low-temperature nitride buffer layer 2, the low-temperature nitride buffer layer 2 comprising gallium nitride, aluminum nitride or aluminum nitride at least one of gallium;

[0046] Step 3, growing a non-doped gallium nitride layer 3;

[0047] Step 4, growing a silicon-doped N-type gallium nitride layer comprising a graphene layer;

[0048] Step 5, growing the luminescent layer 7;

[0049] Step 6, growing a p-type aluminum gallium nitride layer 8 doped with aluminum and magnesium comprising a graphene layer;

[0050] Step 7, growing a p-type gallium nitride layer 10 doped with magnesium;

[0051] Step 8. Keep warm for 20-30 minutes at a tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com