Two-piece type plug-in bus duct

A plug-in, busbar technology, used in cooling busbar devices, fully enclosed busbar devices, etc., can solve problems such as hidden dangers of busbar system safety, reduction of busbar protection level, electrical accidents, etc., and achieve superior structural performance and electrical performance. Improve dynamic stability and thermal stability, improve the effect of safe operation factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

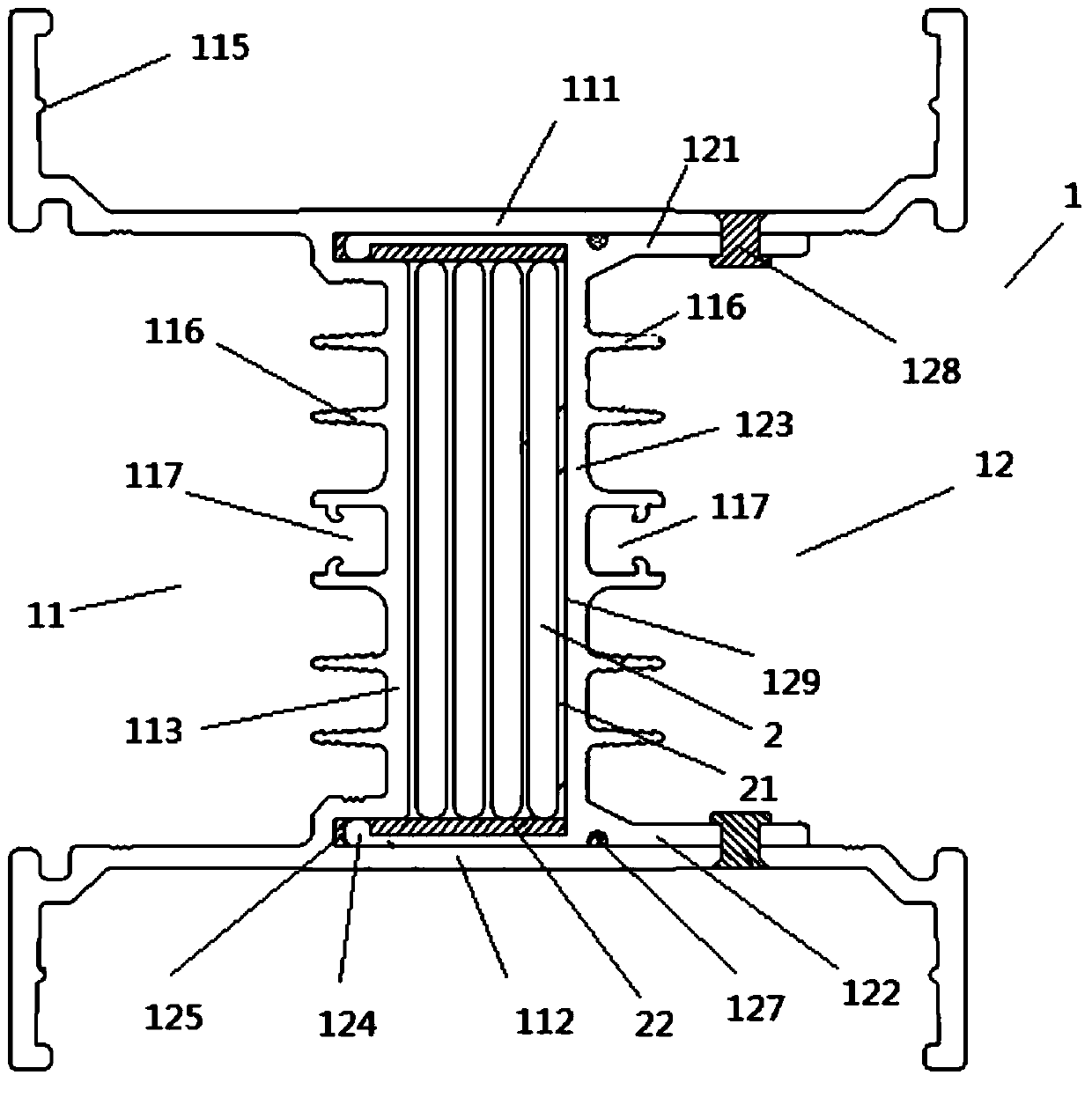

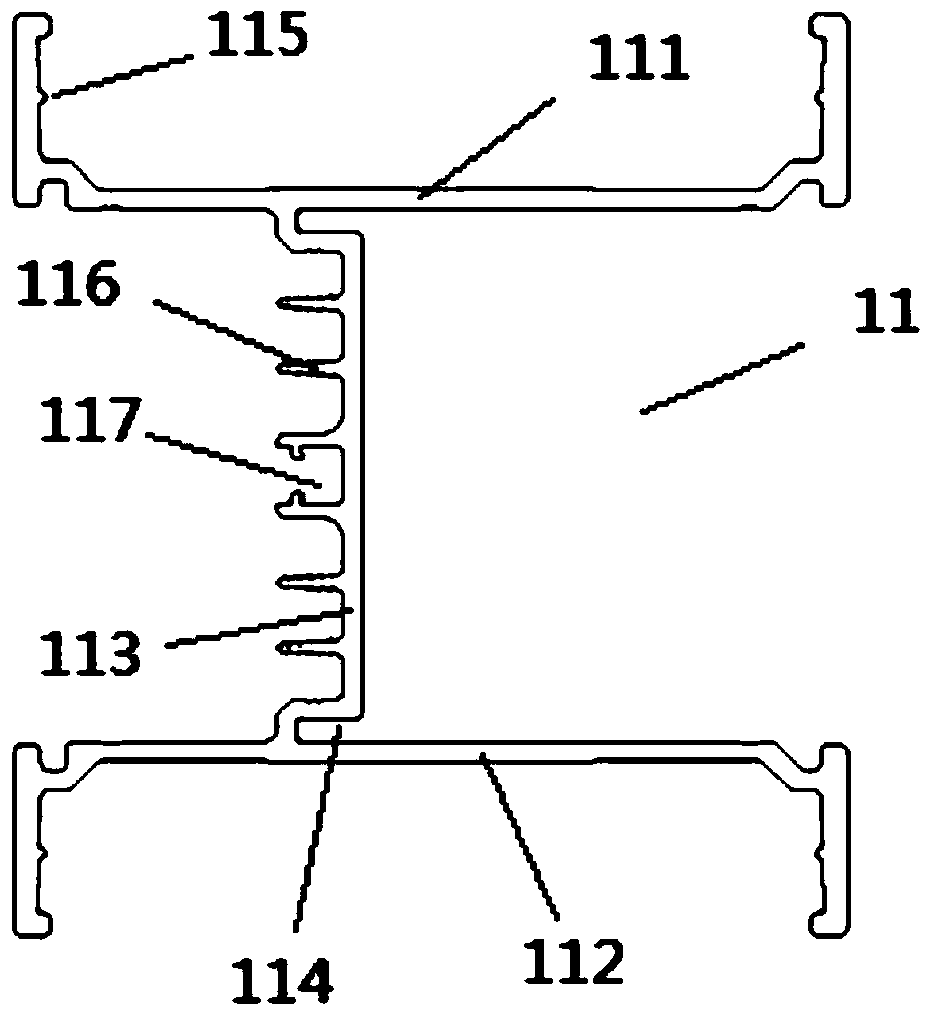

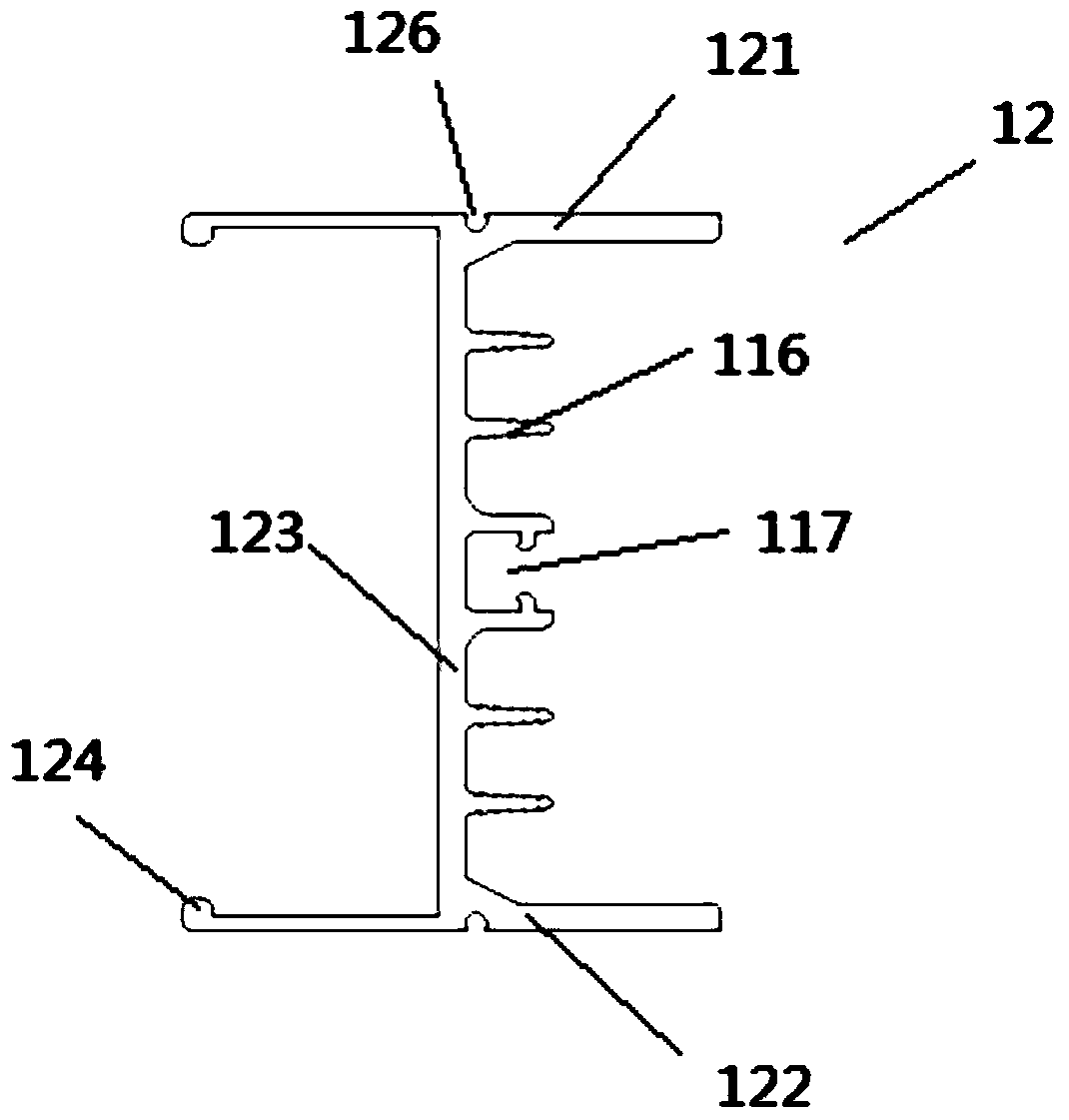

[0026] see Figure 1 to Figure 3 , a two-piece plug-in busway, including a shell 1 and a conductor 2, the shell 1 is made of aluminum-magnesium alloy, the shell 1 includes a main shell 11 and a secondary shell 12, the main The cross-section of the housing 11 is an "I"-shaped structure with grooves. The main housing 11 includes an upper plate 111 of the main housing, a lower plate 112 of the main housing and a middle plate 113 of the main housing. The plate 111, the lower plate 112 of the main housing and the middle plate 113 of the main housing are integrally formed. Insertion slots 114 are respectively provided at the joints, and reinforcing ribs 115 are respectively provided on the struts at both ends of the upper plate 111 of the main housing and the lower plate 112 of the main housing, and the reinforcing ribs 115 improve the structural ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com