Bilateral primary permanent magnetic vernier linear motor

A linear motor, primary technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of increasing the weight of the motor, increasing the weight of the moving parts, increasing the engineering cost, etc., to reduce the primary weight, reduce the manufacturing cost, and improve the dynamic performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

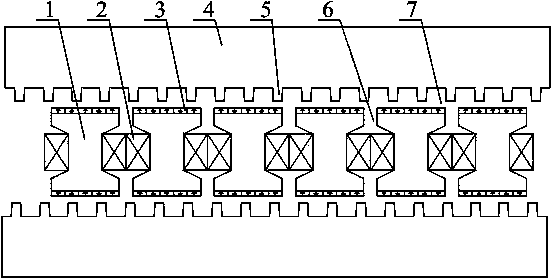

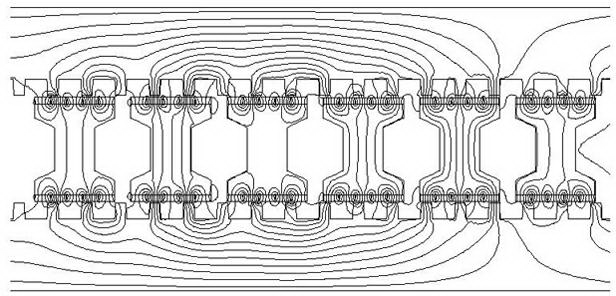

[0024] see figure 1 , the bilateral primary permanent magnet vernier linear motor provided by the present invention is suitable for low-speed and high-thrust working conditions, and can be used as a direct drive motor to run in an electric or power generation state, and its structure includes a motor primary and a motor secondary.

[0025] The motor primary includes a primary iron core 1, an armature winding 2 and a permanent magnet 3; the primary iron cores 1 are uniformly and dispersedly arranged to form a cogged structure of the primary part.

[0026] The primary iron core 1 is an "I" type iron core, and the motor primary has no yoke core, which reduces the weight of the motor primary, thereby improving the dynamic performance.

[0027] The permanent magnets 3 are mounted on the surface of the armature teeth. The magnetization directions of adjacent permanent magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com