Non-isolation step-down LED drive circuit capable of adaptive power supply and working method

A technology of LED drive and power supply circuit, which is applied in the direction of lamp circuit layout, electric light source, lighting device, etc. It can solve the problems that a single LED cannot meet the requirements, and achieve the effect of simplifying the structure, realizing charging and discharging, and realizing on-off control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

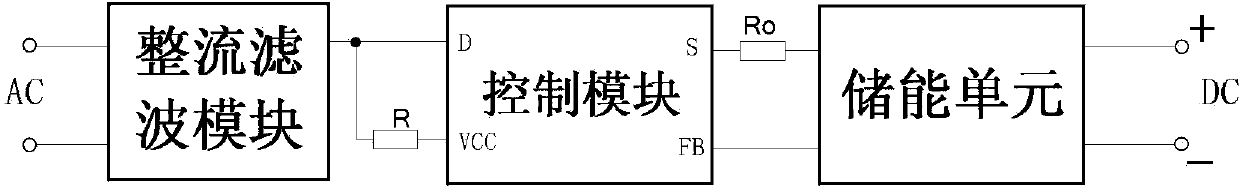

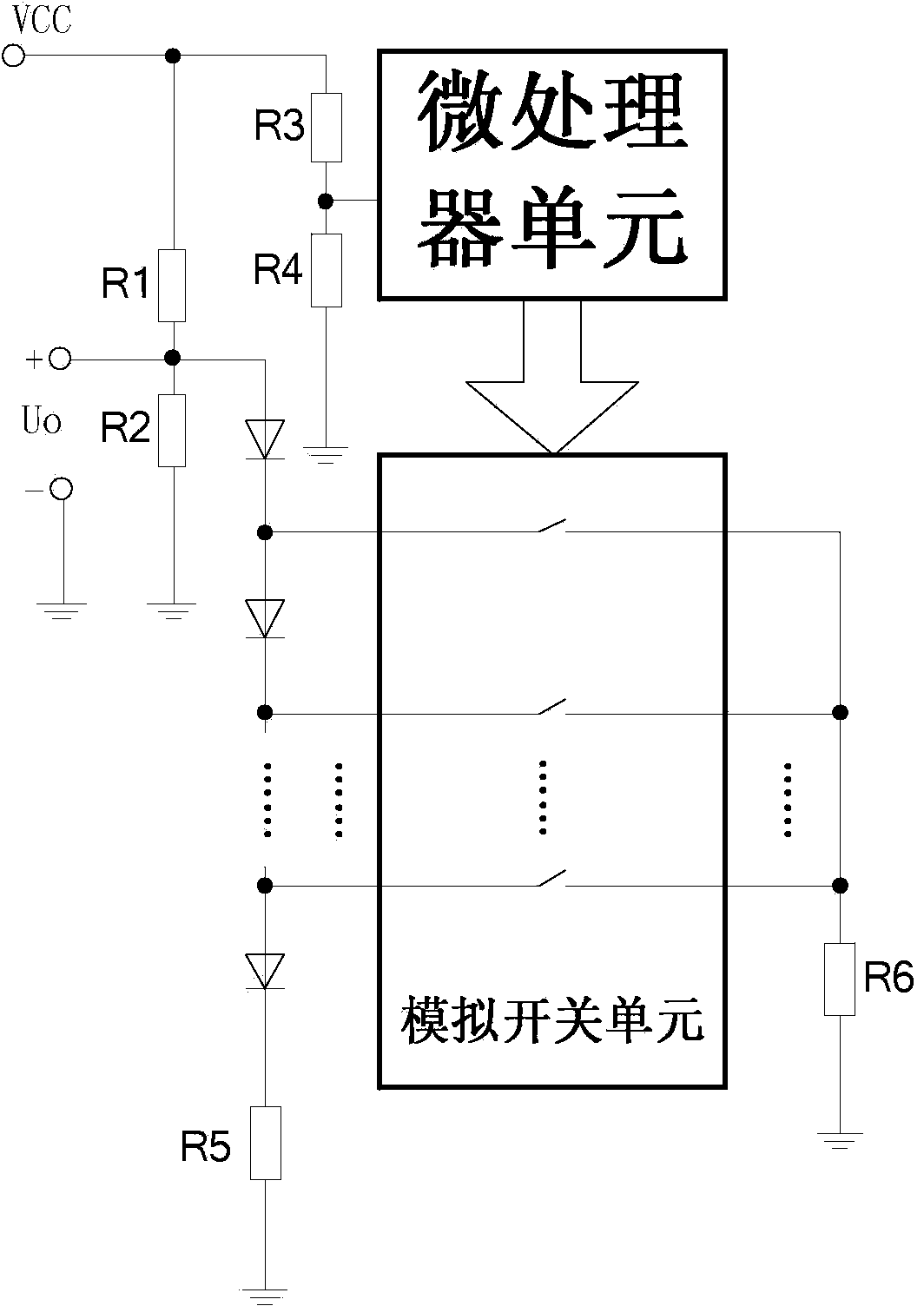

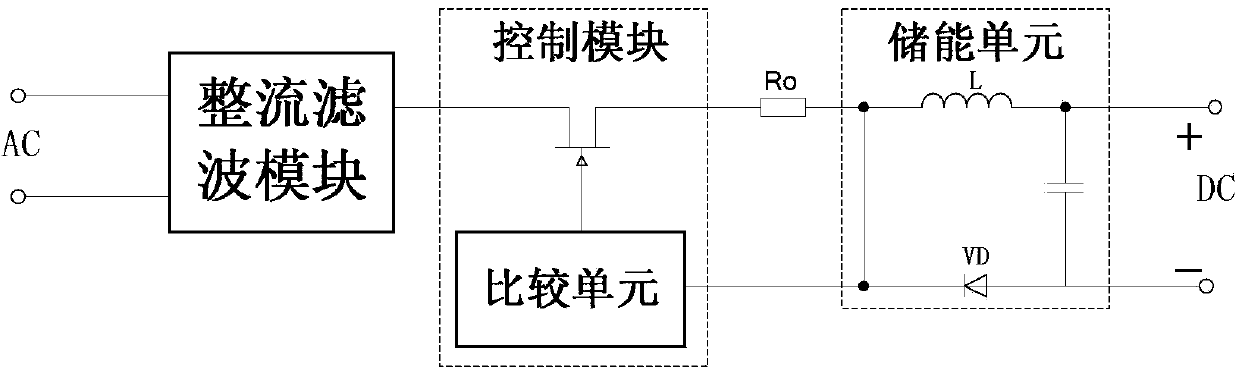

[0022] Such as figure 1 and figure 2 As shown, a non-isolated step-down LED drive circuit for self-adaptive power supply, including: a rectification filter circuit, a control module provided with a switching tube, the power supply end of the control module is connected to the output end of the rectification circuit through a resistor R; An adaptive power supply circuit is provided in the control module, the adaptive power supply circuit includes a microprocessor unit, a step-down unit is composed of first and second resistors connected in series, and a PN junction unit composed of several series connected PN junctions simulates Switch unit; the output end of the step-down unit is connected to the input end of the PN junction unit, and the output end is used as the voltage output end of the adaptive power supply circuit; nodes are arranged between the PN junctions, each node respectively connected to each switch input end of the analog switch unit, each switch output end of t...

Embodiment 2

[0031] On the basis of Embodiment 1, the present invention also provides a working method of a self-adaptive power supply non-isolated step-down LED drive circuit, including: the processor unit is adapted to control the analog switch unit according to the sampled voltage value Open or close the corresponding switch to increase or decrease the PN junction in series to stabilize the output voltage of the adaptive power supply circuit; that is, when the sampling voltage value increases, reduce the PN junction in series; if the sampling When the voltage value drops, the PN junction in series is added.

[0032] The current sampling terminal of the control module obtains the current sampling signal I from the cathode of the freewheeling tube VD in the energy storage unit CS , by judging the current sampling signal I CS to control the switching off, on or holding of the switching tube.

[0033] The control module includes: suitable for current sampling signal I CS A sampling resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com