Grease composition for whipped cream

A technology of oil composition and whipping cream, which is applied in entertainment and other fields, can solve the problems of high melting point and lower melting in the mouth, and achieve the effects of excellent melting in the mouth and excellent emulsification stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

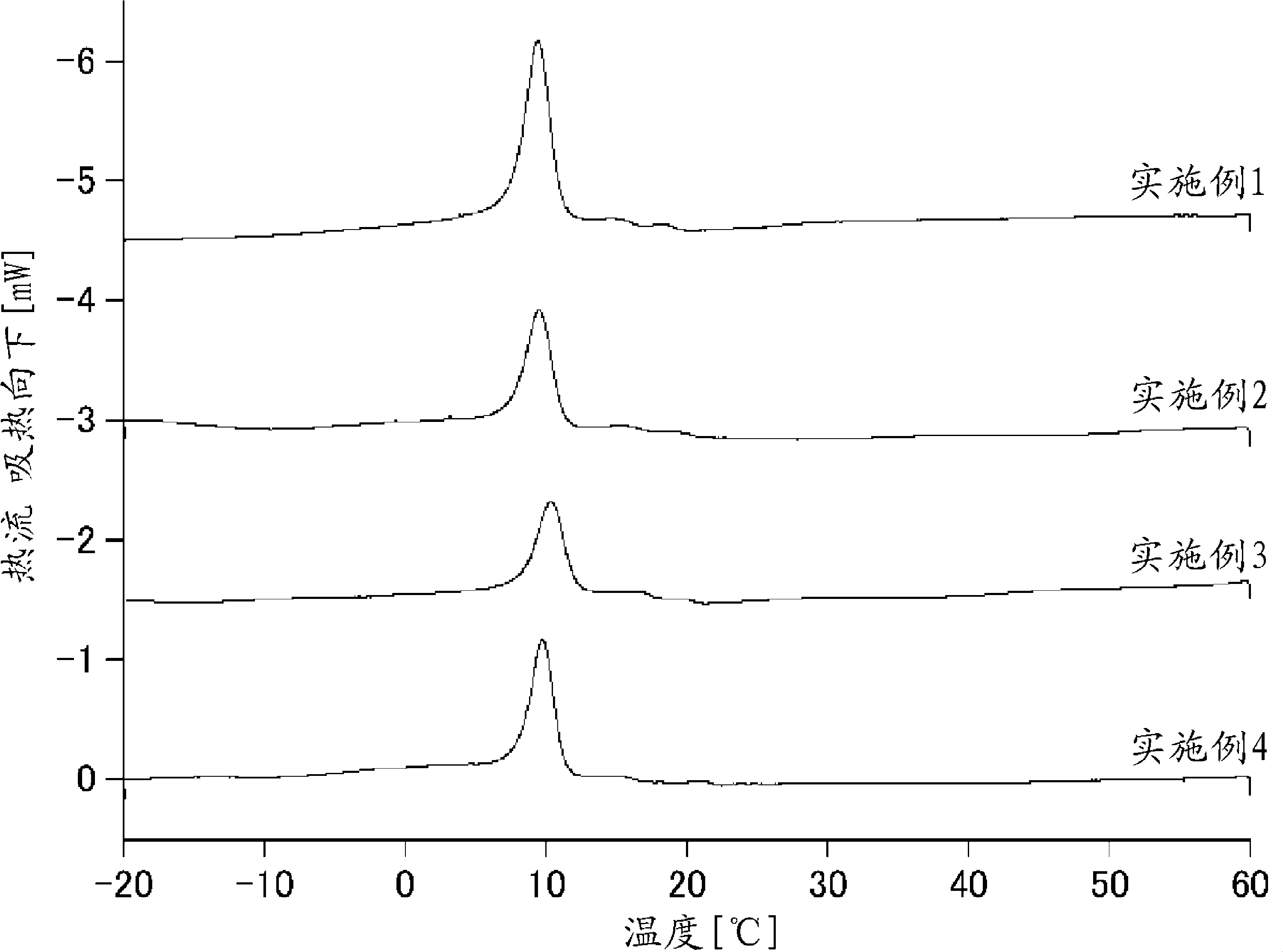

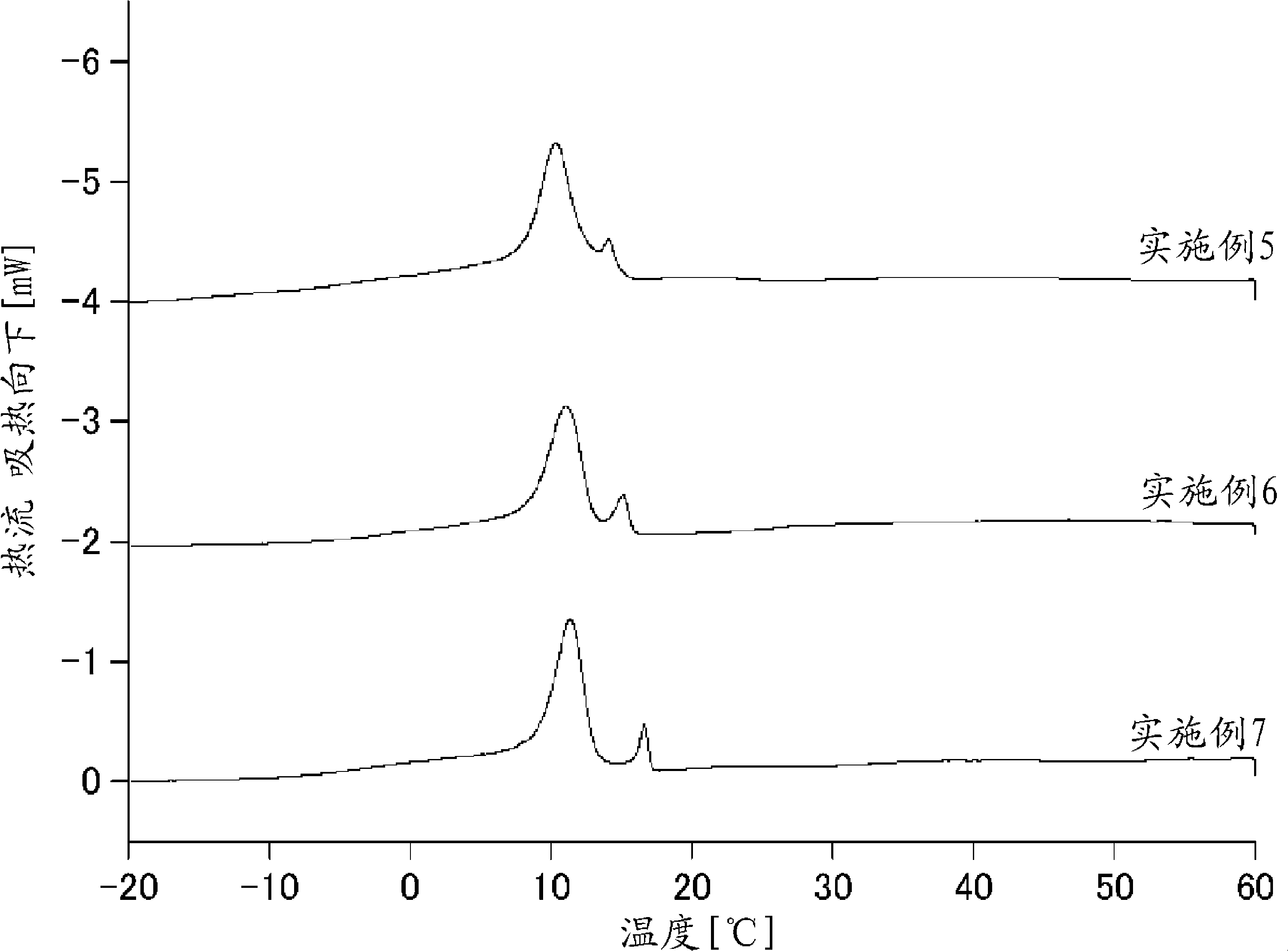

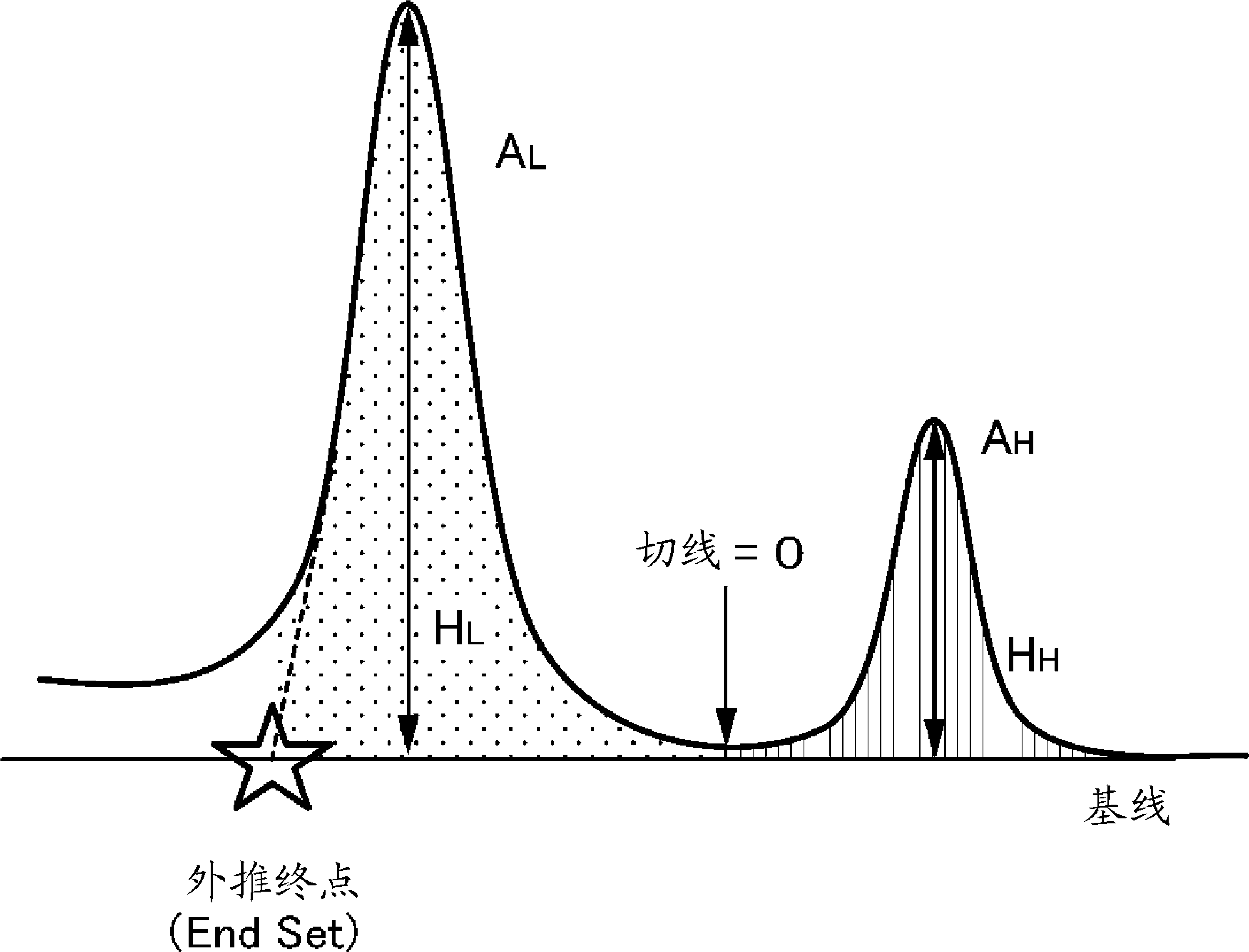

Image

Examples

Embodiment

[0075] fat preparation method

[0076] (1) Using 0.143% sodium methoxide as a catalyst, a mixed oil of 40% by mass coconut oil and 60% by mass of palm oil was subjected to a non-selective transesterification reaction at 90°C for 30 minutes to decolorize and deodorize to obtain Grease 1. The melting point of Grease 1 is 34°C. The amount of trans fatty acid was 0.5% by mass.

[0077] (2) Using 0.143% sodium methoxide as a catalyst, non-selective transesterification was carried out at 90° C. for 30 minutes on a mixed oil of 35 mass % coconut oil and 65 mass % palm oil to decolorize and deodorize to obtain oil 2. The melting point of fat 2 is 34°C. The amount of trans fatty acid was 1.1% by mass.

[0078] (3) Using 0.12% sodium methoxide as a catalyst, carry out non-selective transesterification reaction for 30 minutes at 90°C on a mixed oil of 40 mass % palm kernel oil and 60 mass % palm oil to decolorize and deodorize to obtain oil 3 . The melting point of fat 3 is 34°C. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com