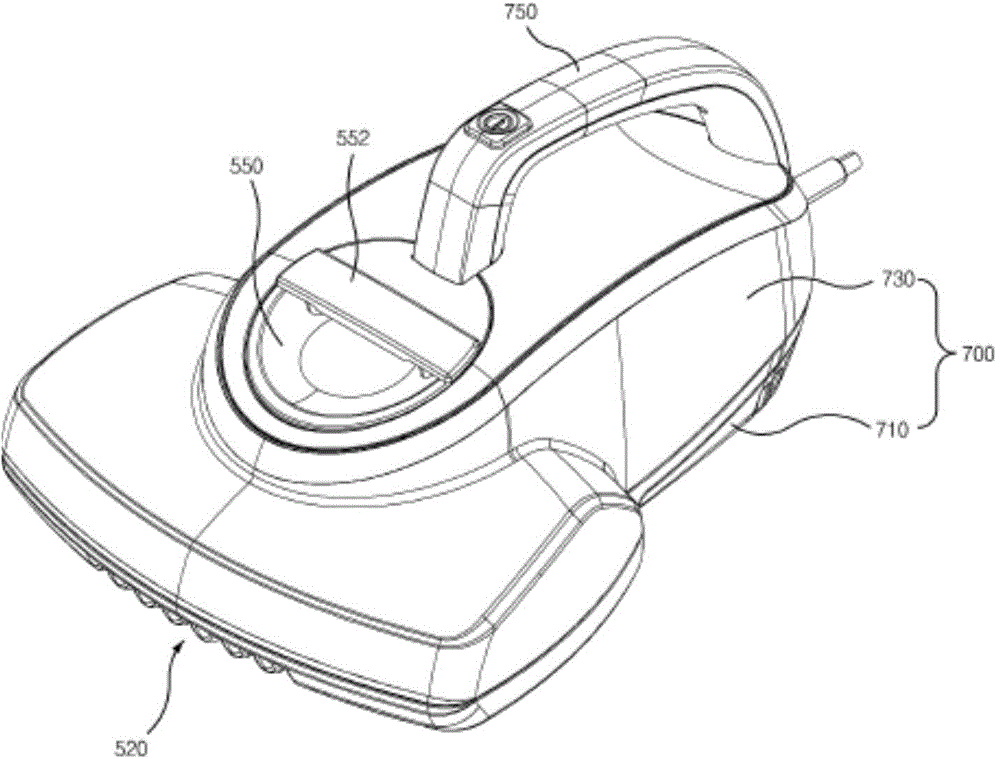

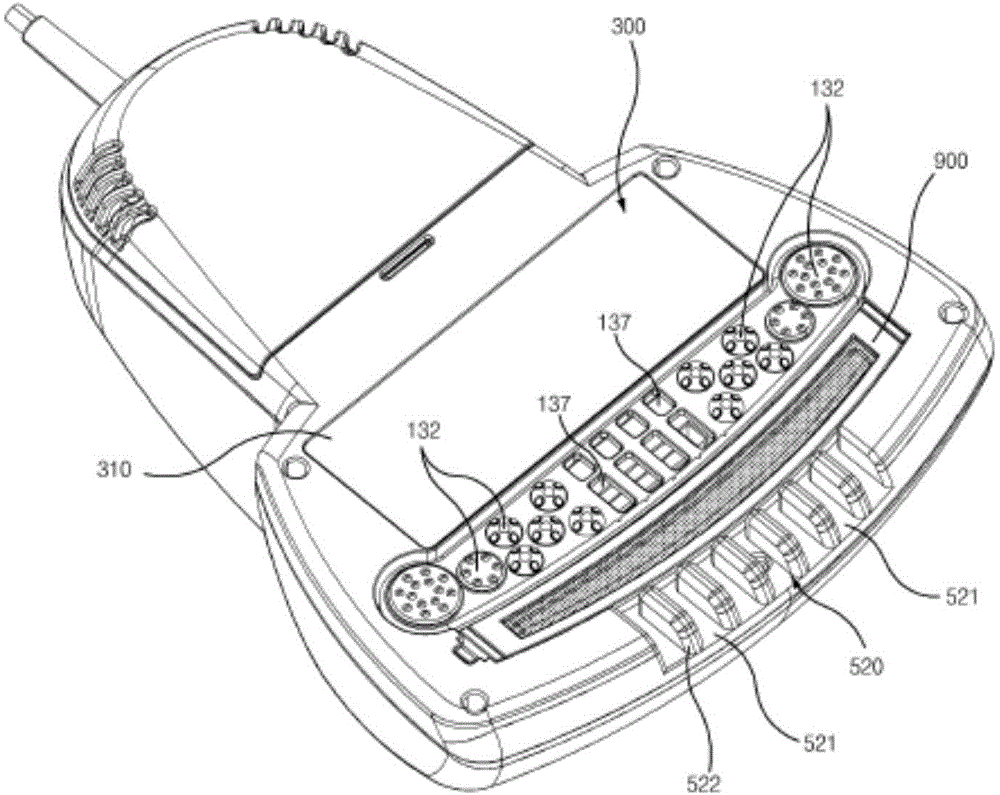

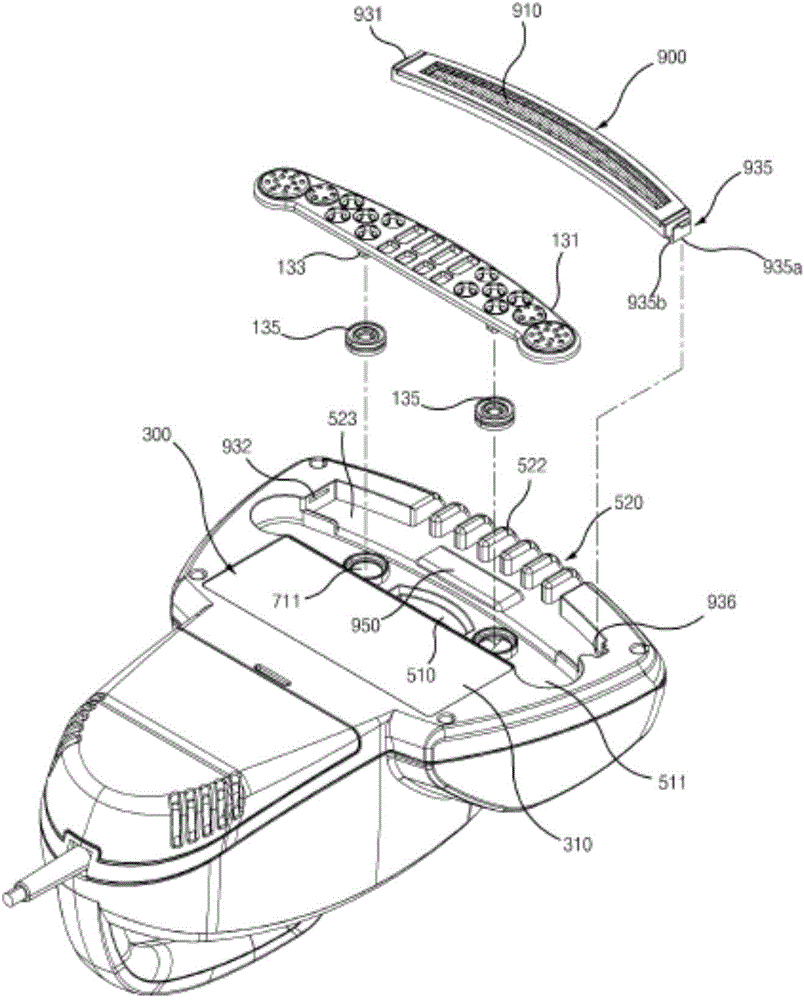

Vacuum Dust Collector

A technology for vacuum cleaners and suction nozzles, which is applied in the direction of vacuum cleaners, suction nozzles, cleaning equipment, etc. It can solve the problems of complex motor structure and cumbersome assembly process, and achieve the effects of improving scraping efficiency, convenient cleaning, and improving suction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with specific examples. It should be understood that these embodiments are used to illustrate the basic principles, main features and advantages of the present invention, and the present invention is not limited by the scope of the following embodiments. The implementation conditions used in the examples can be further adjusted according to specific requirements, and the unspecified implementation conditions are usually the conditions in routine experiments.

[0031] In addition, the "sterilization" mentioned in the specification and claims of the present invention is a broad concept including the elimination of bacteria and pests, while the narrowly defined "insecticide" is used only to emphasize the killing of pests, and is used to distinguish it from the term sterilization.

[0032] In addition, the vacuum cleaner in the present invention is interpreted as a vacuum cleaner with four ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap