Energy-efficient transmission device

A transmission, high-efficiency and energy-saving technology, applied in the field of high-efficiency and energy-saving transmission and transmission, can solve the problems of damage to the reducer, troublesome assembly, overload of the reducer, etc., to avoid overload damage, reduce contact strength, and easy to assemble.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

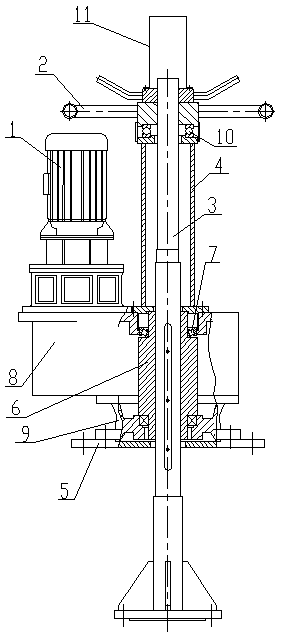

[0011] A high-efficiency energy-saving transmission device, including a reducer 1, a hand wheel 2, a transmission shaft 3, an adjustment bracket 4 and a base plate 5, the upper end of the output gear 6 in the reducer 1 is installed on the upper end of the reducer casing 8 through a bearing I7, and the output The lower end of the gear 6 passes through the reducer casing 8 and is installed in the through hole of the underframe 9 at the lower end of the reducer casing 8 through the bearing I7. The underframe 9 is installed on the bottom plate 5. Internally connected to the through hole of the output gear 6, the transmission shaft 3 can move up and down in the axial through hole of the output gear 6, the upper end of the transmission shaft 3 is covered with an adjustment bracket 4, and the hand wheel 2 is connected with the screw thread on the outer surface of the upper end of the transmission shaft 3 , There is a bearing II10 between the hand wheel 2 and the adjustment bracket 4; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com