Spring steel wire production process used for controlling inclusion substances

A production process, spring steel technology, applied in the field of metallurgy, to achieve the effect of meeting the fatigue life requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of spring steel wire rod production process for controlling inclusion, comprises the steps:

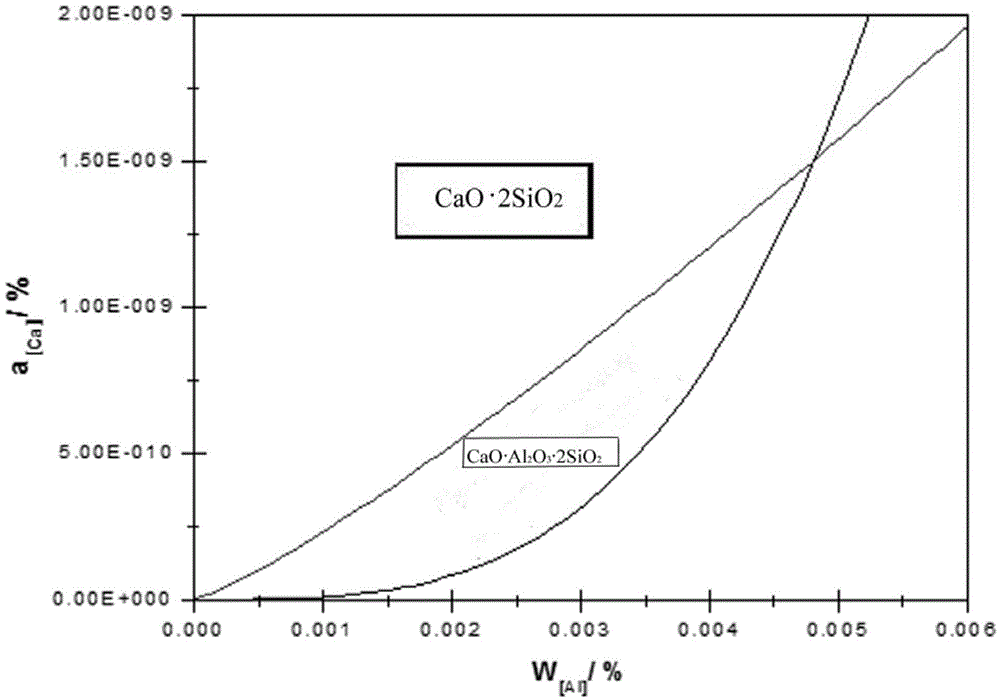

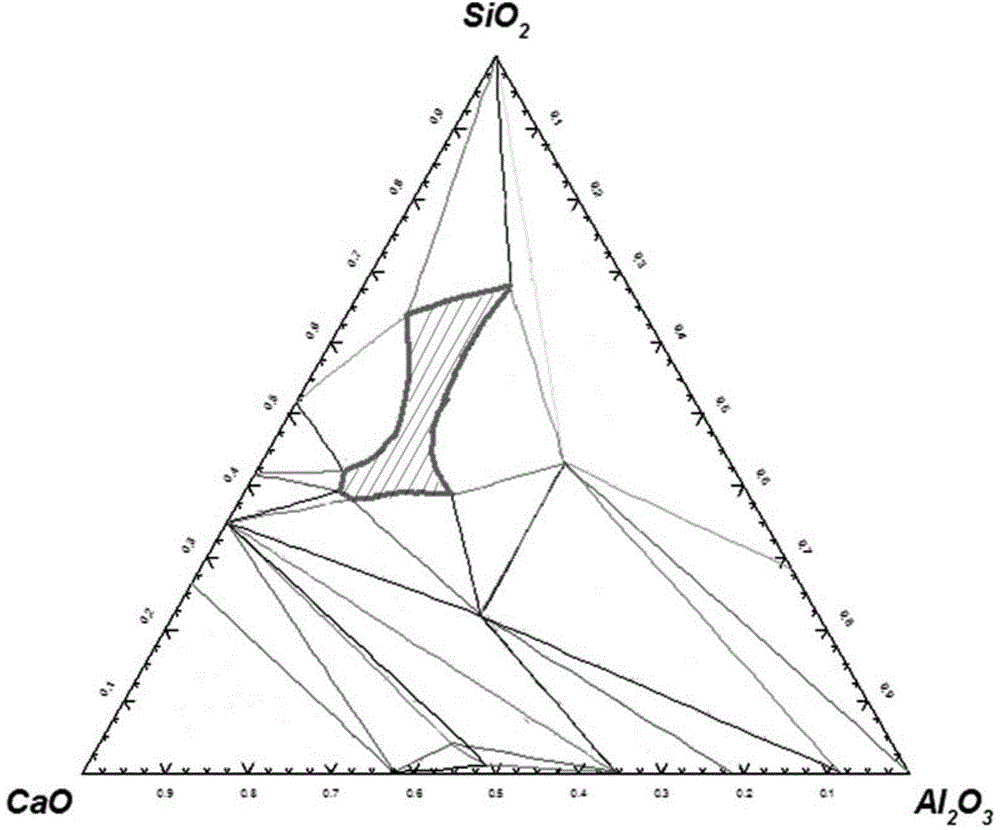

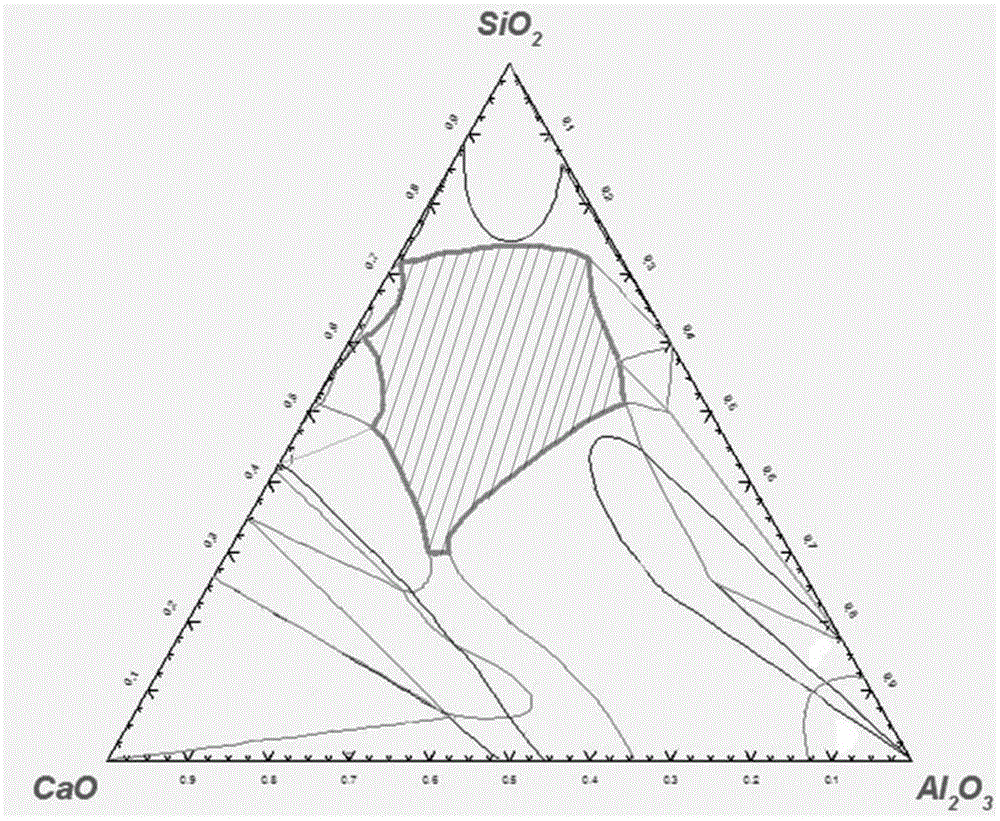

[0031] 1) Adopt the aluminum-free deoxidation process of Si / Mn smelting spring steel 55SiCr, avoid using aluminum in the smelting process, and reduce the Al and Al brought into by slag, lining, alloy, etc. 2 o 3 , to control the W in molten steel [Al] -6 、a [Ca] -9 ;

[0032] 2) Converter top-bottom combined blowing: use special ferrosilicon, control Als<0.0020% in the steel; add light-burned magnesium balls at 0.8kg per ton of steel; control carbon at 0.08wt% at tapping; control the basicity of the final slag at R= 2.5;

[0033] 3) Argon blowing treatment at Ar station: Bottom blowing argon treatment is adopted in the whole process, argon pressure control: 0.4MPa, argon flow rate: 7.0Nm 3 / min, to avoid secondary oxidation and gas absorption;

[0034] 4) Refining by argon blowing in LF ladle: the refining time is 45 minutes, and argon is blown throughout the refin...

Embodiment 2

[0047] A kind of spring steel wire rod production process for controlling inclusion, comprises the steps:

[0048] 1) Adopt the aluminum-free deoxidation process of Si / Mn smelting spring steel 55SiCr, avoid using aluminum in the smelting process, and reduce the Al and Al brought into by slag, lining, alloy, etc. 2 o 3 , to control the W in molten steel [Al] -6 、a [Ca] -9 ;

[0049] 2) Converter top-bottom combined blowing: use special ferrosilicon, control Als<0.0020% in the steel; lightly burnt magnesium balls are added at 1.1kg per ton of steel; tap carbon is controlled at 0.14%; final slag basicity is controlled at R=4.4 ;

[0050] 3) Argon blowing treatment at Ar station: argon pressure control: 0.5MPa, argon flow rate: 8.0Nm 3 / min, to avoid secondary oxidation and gas absorption;

[0051] 4) Refining by argon blowing in LF ladle: the refining time is 45 minutes, and argon is blown throughout the refining process. The argon blowing process follows three different st...

Embodiment 3

[0055] A kind of spring steel wire rod production process for controlling inclusion, comprises the steps:

[0056] 1) Adopt the aluminum-free deoxidation process of Si / Mn smelting spring steel 55SiCr, avoid using aluminum in the smelting process, and reduce the Al and Al brought into by slag, lining, alloy, etc. 2 o 3 , to control the W in molten steel [Al] -6 、a [Ca] -9 ;

[0057] 2) Converter top-bottom combined blowing: use special ferrosilicon, control Als<0.0020% in steel; add light-burned magnesium balls by 1.2kg per ton of steel; control target of tapping carbon 0.08%; control target of final slag basicity R=3.0 ;

[0058] 3) Argon blowing treatment at Ar station: argon pressure control: 0.6MPa, argon flow rate: 9.0Nm 3 / min, to avoid secondary oxidation and gas absorption;

[0059] 4) Refining by argon blowing in LF ladle: the refining time is 30 minutes, and argon is blown throughout the refining process. The argon blowing process follows three different stages ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap