Tool for horizontal series connection casting and using method

A horizontal and tooling technology, applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of inconvenient transportation, cumbersome operation, troubled production enterprises, etc., and achieve the effect of reducing processes, easy stacking and leveling, and convenient hoisting and transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

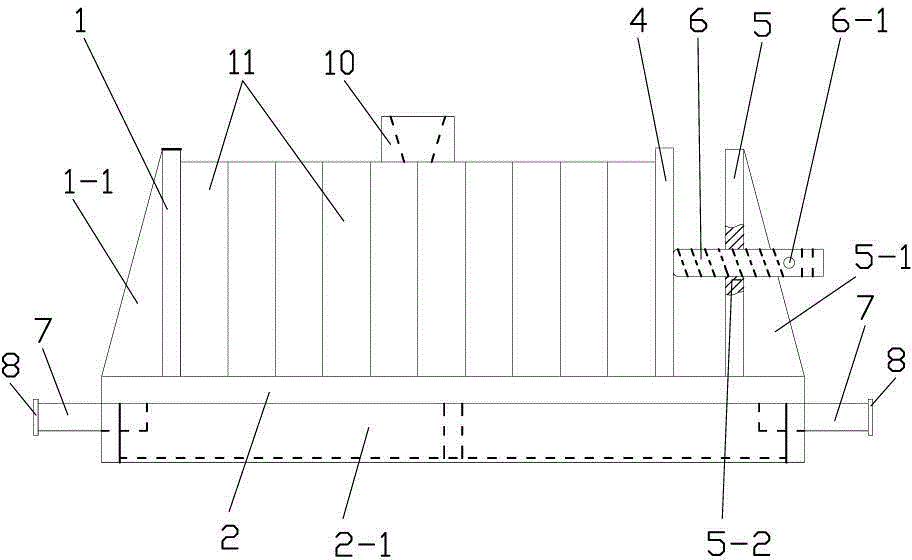

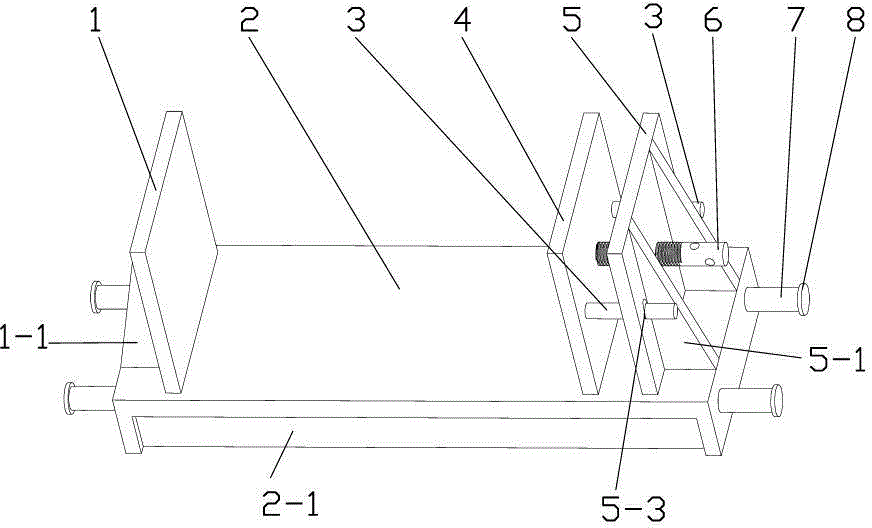

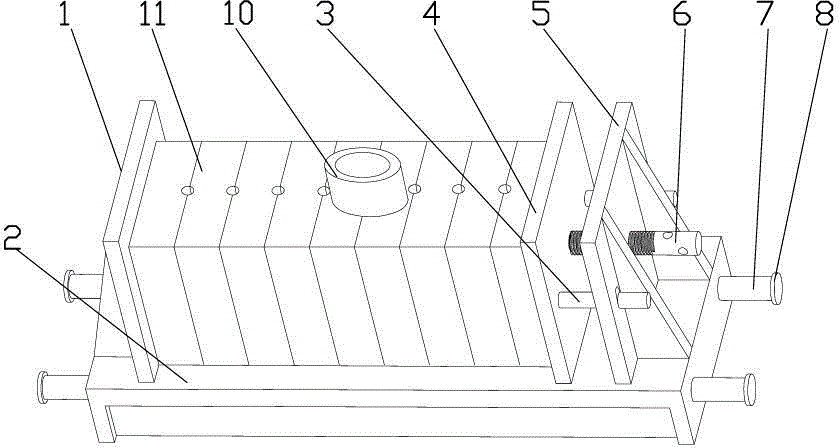

[0025] Such as figure 1 , 2 , 3, the tooling for horizontal tandem casting of the present invention includes a bottom bracket 2, two hangers 7 are respectively arranged on the left and right sides of the bottom bracket 2, and a left support plate 1, a right support plate 5, The movable plate 4, two positioning guide pins 3 and the fastening screw 6, wherein the left support plate 1 and the right support plate 5 are respectively fixed on the two ends of the upper surface of the bottom bracket 2 and arranged face to face, the left support plate 1 and the outside of the right support plate 5 all have support plate reinforcing ribs 1-1, 5-1, the bottom of the bottom bracket 2 has bracket reinforcing ribs 2-1, and the right supporting plate 5 has internal threads Screw guide hole 5-2 and guide pin hole 5-3, guide pin hole 5-3 is two and is respectively positioned at the both sides of screw guide hole 5-2, and described fastening screw rod 6 is threaded on screw rod In the guide h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com