Knife rest

A tool holder and tool handle technology, which is applied in the field of tool holders for processing the outer diameter of slender shafts, can solve problems such as straightness indicators that cannot meet the requirements, bending deformation of slender shafts, and hindering parts processing, etc., to achieve good processing effects and eliminate Bending deformation, the effect of ensuring the processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

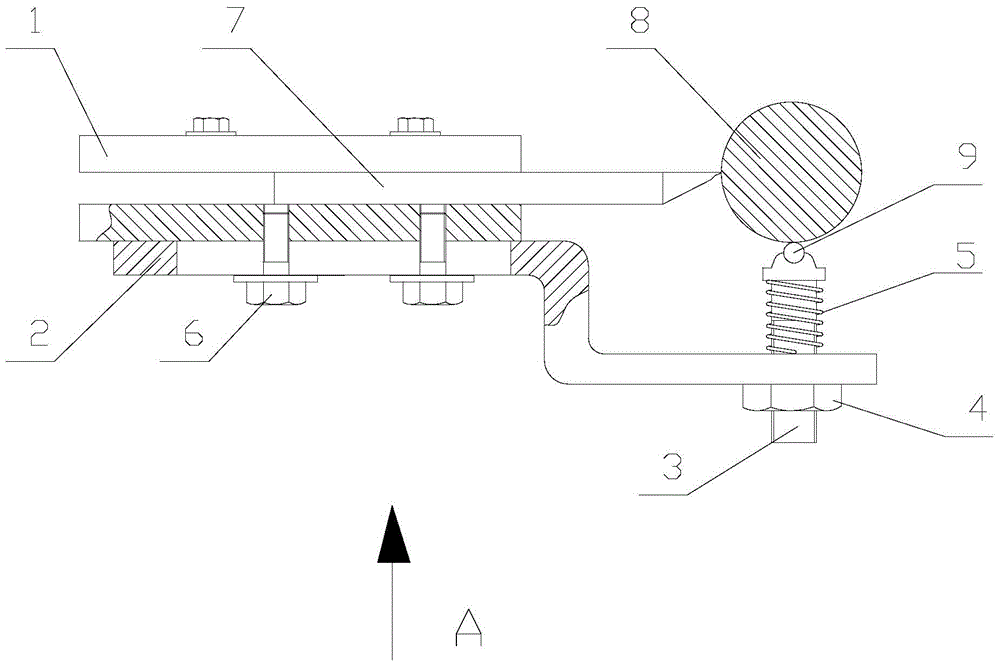

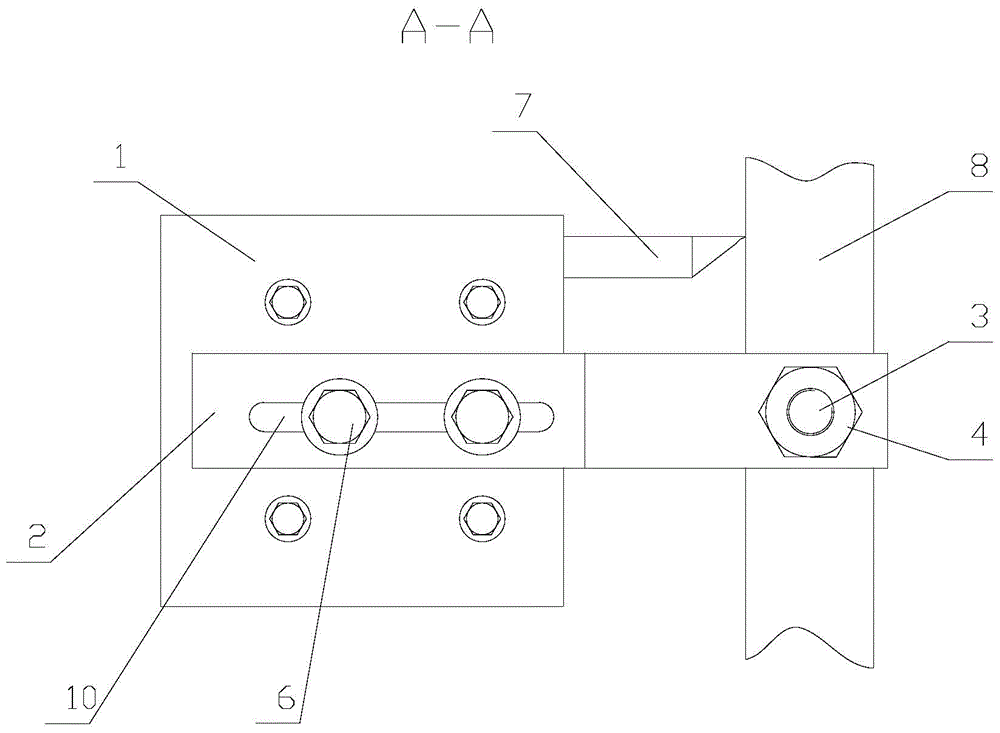

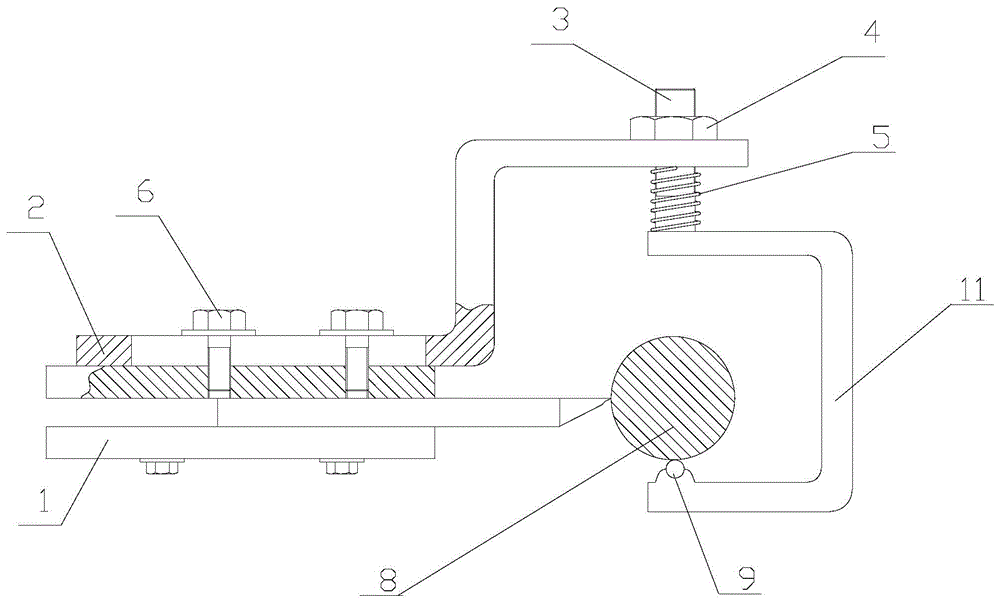

[0011] As shown in the figure, the knife holder includes a handle seat 1, a support arm 2, an adjustment screw pile 3, an adjustment nut 4, a compression spring 5, and a fastening bolt 6, and a turning tool 7 is installed on the handle seat 1. The support arm 2 is fixed on the lower part of the handle seat 1 by the fastening bolt 6, the front end of the support arm 2 extends to the bottom of the elongated shaft 8 to be processed, and a through hole is arranged below the axis of the elongated shaft 8, and the adjustment screw The pile 3 passes through the through hole of the support arm 2 and is provided with an adjustment nut 4 matched with the adjustment screw pile 3 at the bottom of the support arm 2, and a compression spring 5 is provided at the top, and one end of the compression spring 5 is pressed on the support arm 2, the other end is pressed on the step provided on the adjustment screw pile 3, and the adjustment screw pile 3 can be connected with the slender shaft 8 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com