Mobile gantry type digital control massive plate leveling hydraulic press

A gantry-type hydraulic machine technology, applied in the field of hydraulic machines, can solve problems such as the increased gap between the gantry and the workbench guide rail, the lack of accurate leveling of the workpiece, and the easy bending and deformation of the roller shaft. It achieves compact structure, convenient operation, and The effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

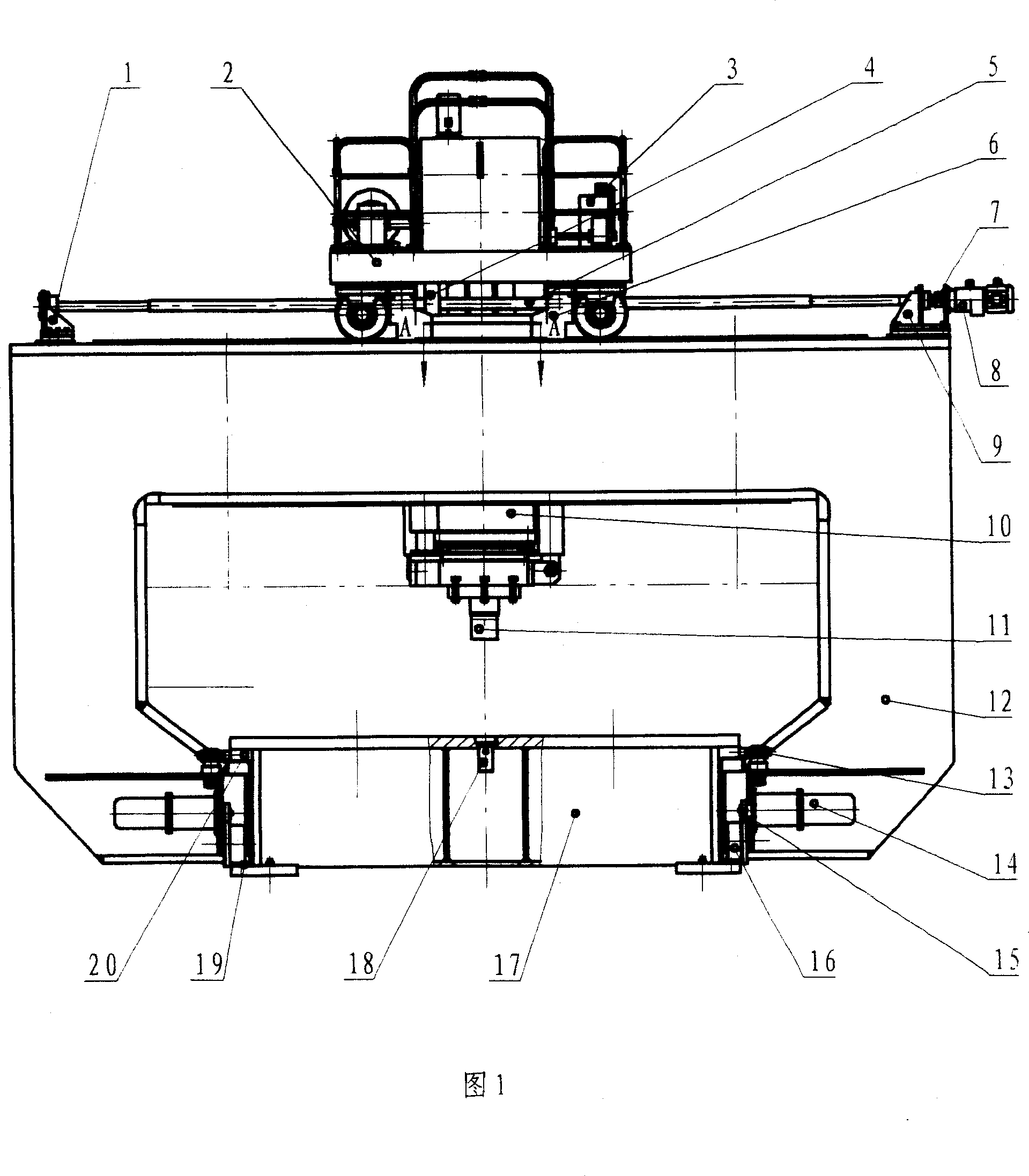

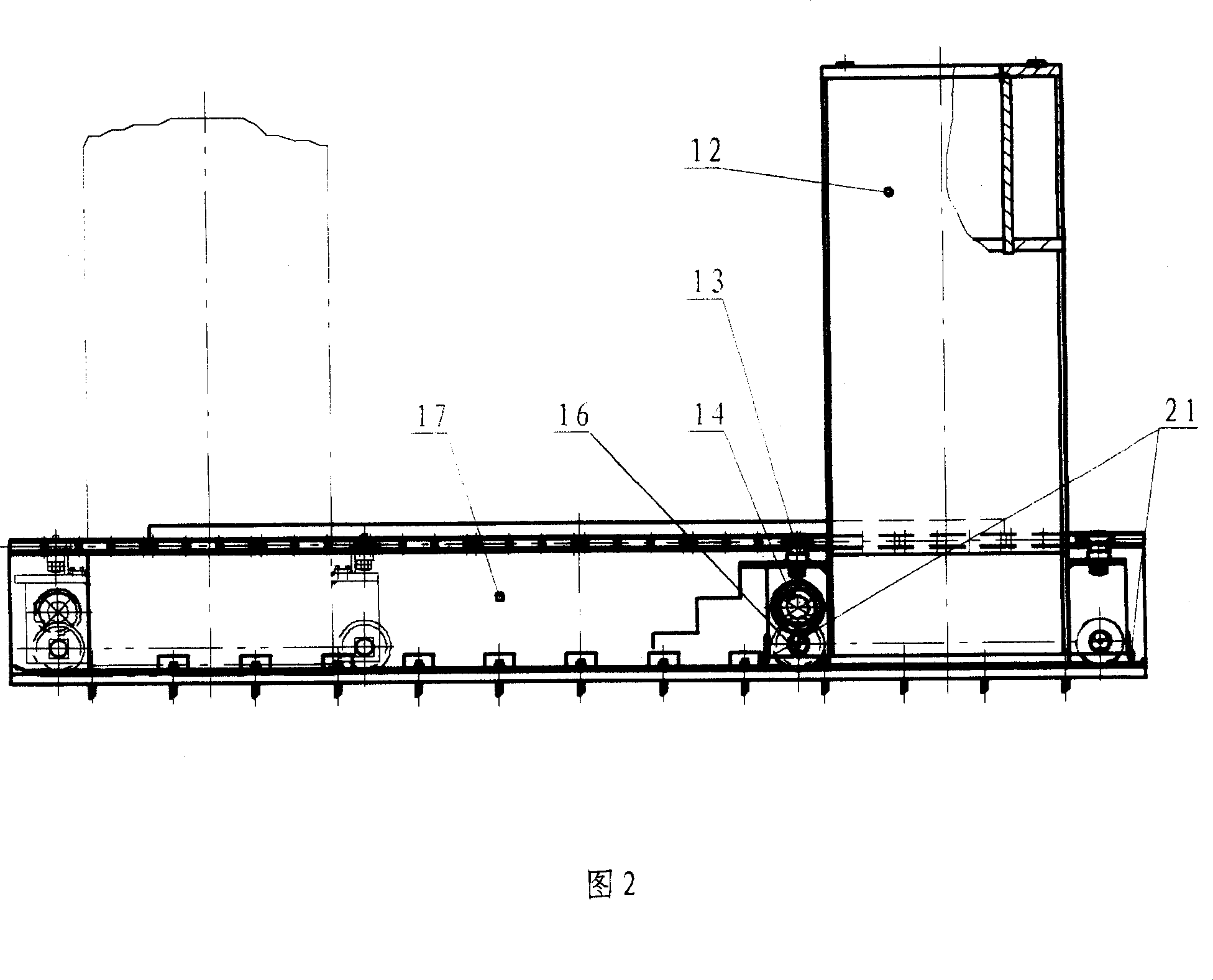

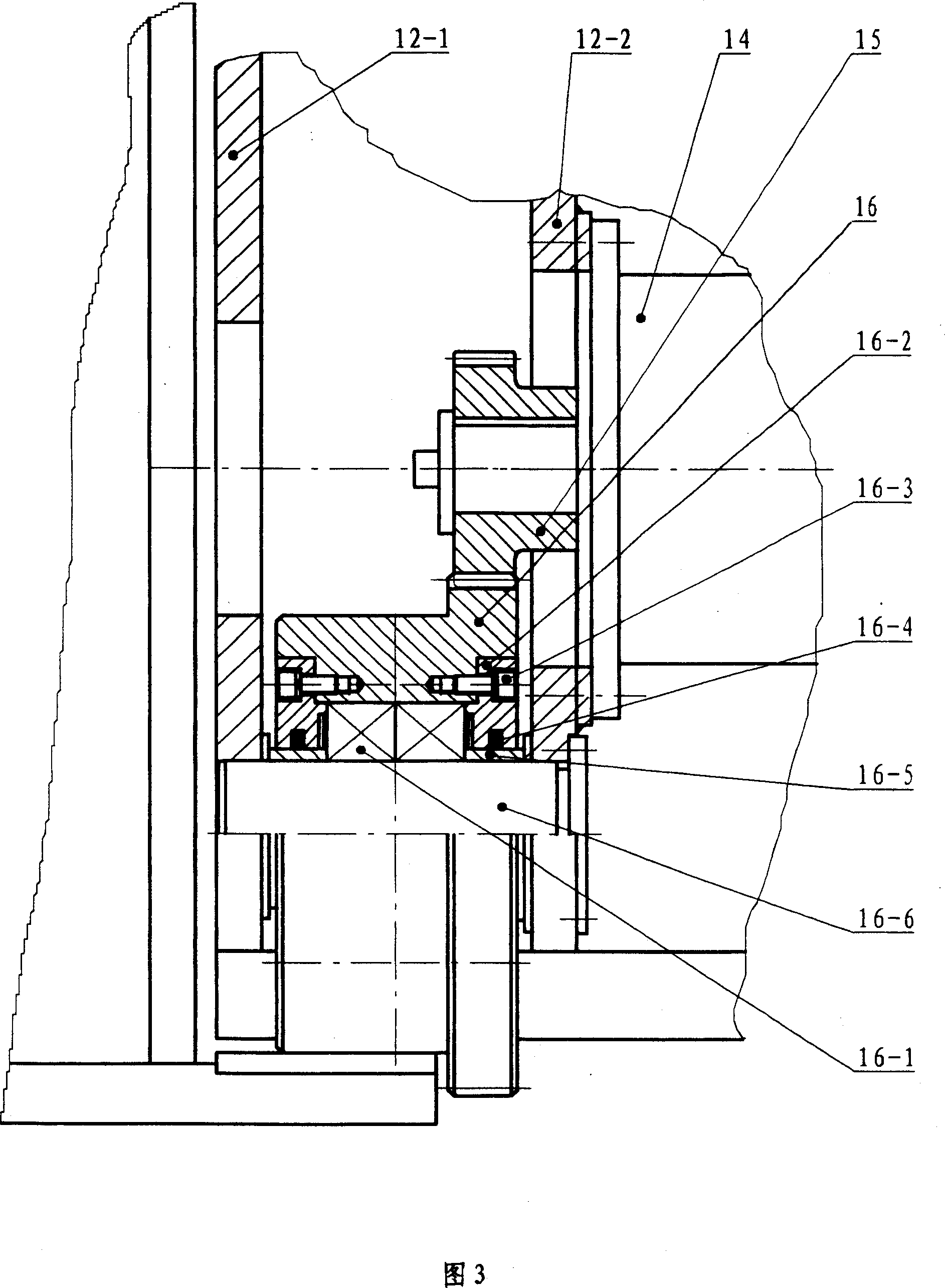

[0015] Please refer to Fig. 1 and shown in Fig. 2, the fixed workbench 17 is a cuboid, the center part of the fixed workbench is equipped with a jacking cylinder 18 for jacking up the workpiece, and both sides of the fixed workbench are equipped with upper guide rails 20 and lower guide rails 19 The gantry 12 across the two sides of the fixed workbench is installed between the upper and lower guide rails on both sides of the fixed workbench. The bottom of the gantry is equipped with guide wheels 13 rolling on the guide rails on the fixed workbench. A support plate 12-2 integrally welded with the gantry is fixedly installed, as shown in Figure 3 . A toothed roller 16 rolling on the lower guide rail of the fixed workbench is installed between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com