Power Supply Device For Electrical Arc Welding And Controlling Method Therefor

A technology of arc welding and power supply device, which is applied in the direction of arc welding equipment, welding equipment, manufacturing tools, etc. It can solve the problems of welding performance degradation and hinder welding continuation, and achieve good arc welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0044] Hereinafter, the first embodiment of the power supply device for arc welding and the control method of the power supply device for arc welding will be described.

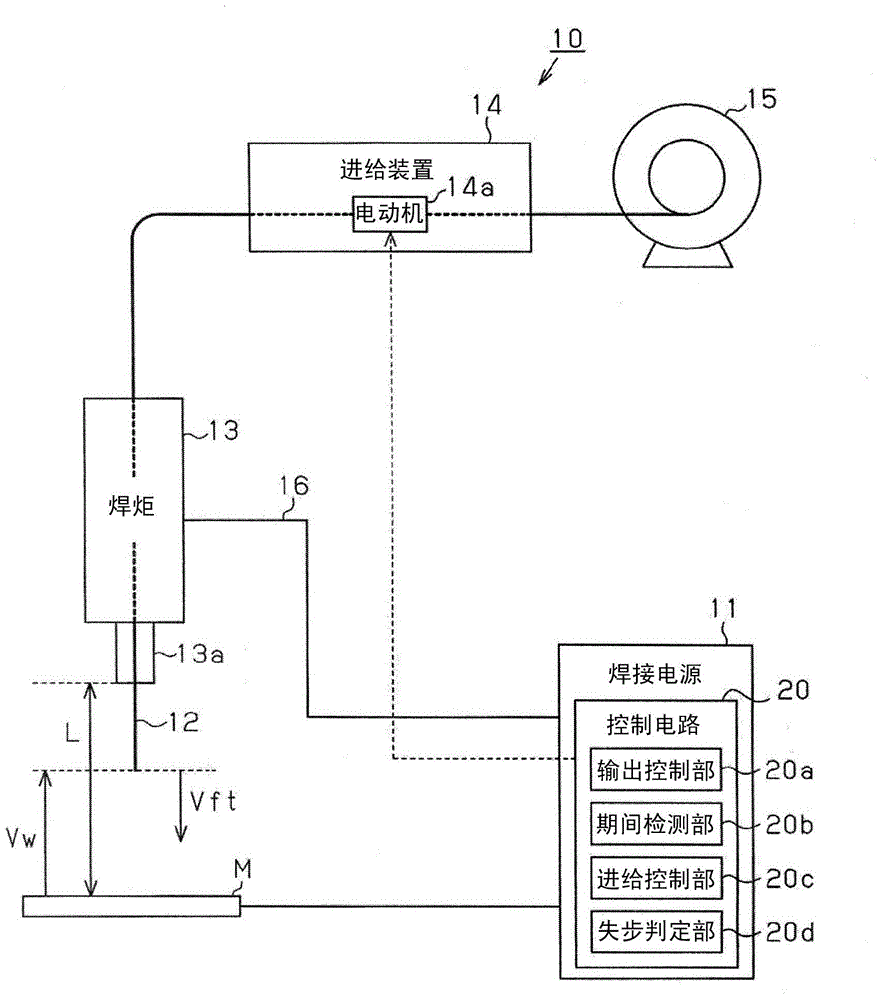

[0045] Such as figure 1As shown, the arc welding machine 10 includes not only an arc welding power supply device 11 that generates an output power suitable for arc welding, but also a device for feeding and holding the welding wire 12 as a discharge electrode that generates an arc. A welding torch 13 , a feeding device 14 for feeding the welding wire 12 , and a wire reel 15 on which the welding wire 12 is wound.

[0046] The welding torch 13 is connected to a power supply device 11 via a power cable 16 and receives power supply from the power supply device 11 . The welding torch 13 is equipped with the feeding chip (chip) 13a which feeds the welding wire 12. As shown in FIG. The power feeding chip 13 a is in electrical contact with the welding wire 12 in order to supply the output power generated by the pow...

no. 2 Embodiment approach

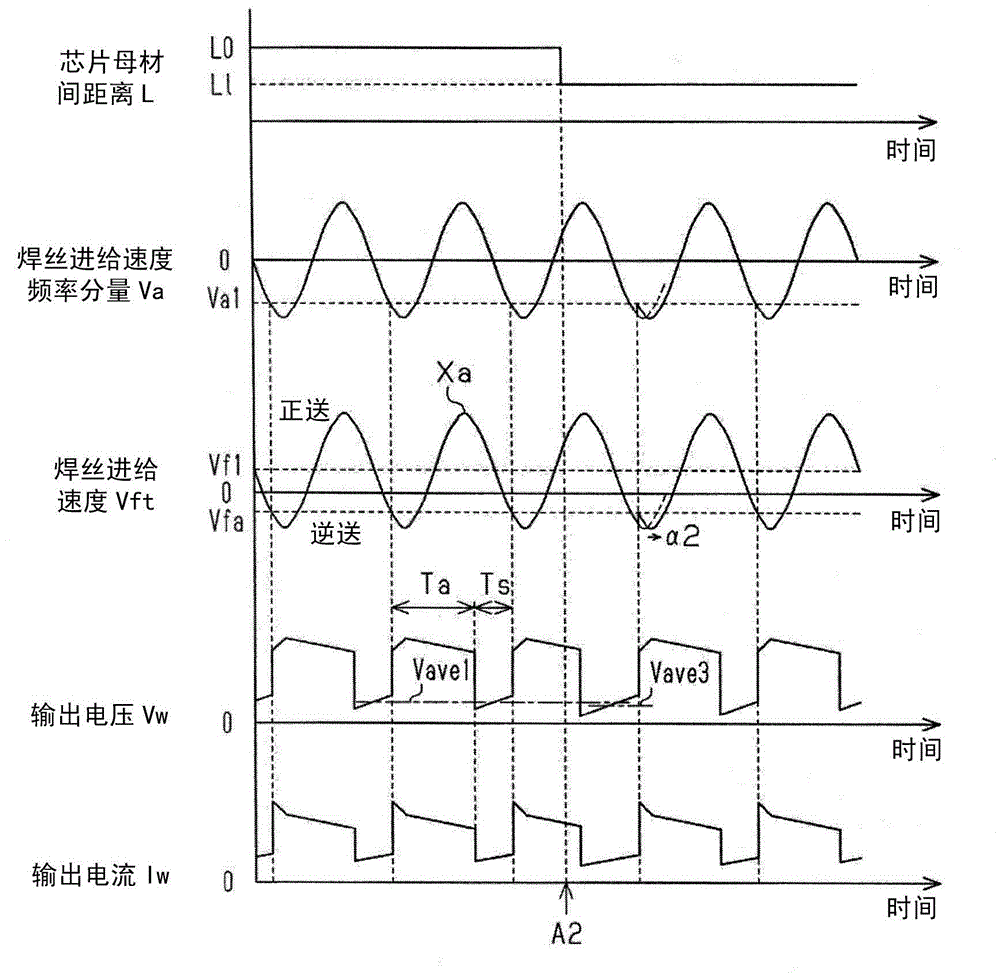

[0076] Hereinafter, the second embodiment of the power supply device for arc welding and the control method of the power supply device for arc welding will be described.

[0077] In this embodiment, the control form of the feed control part 20c of the control circuit 20 differs from the previous 1st Embodiment. In the first embodiment, the phase adjustment (fixed amplitude) of the change curve Xa of the feed speed Vft of the welding wire 12 was performed, whereas in the present embodiment, the change curve of the feed speed Vft of the welding wire 12 is performed. Control form of amplitude adjustment (phase fixation) of Xa.

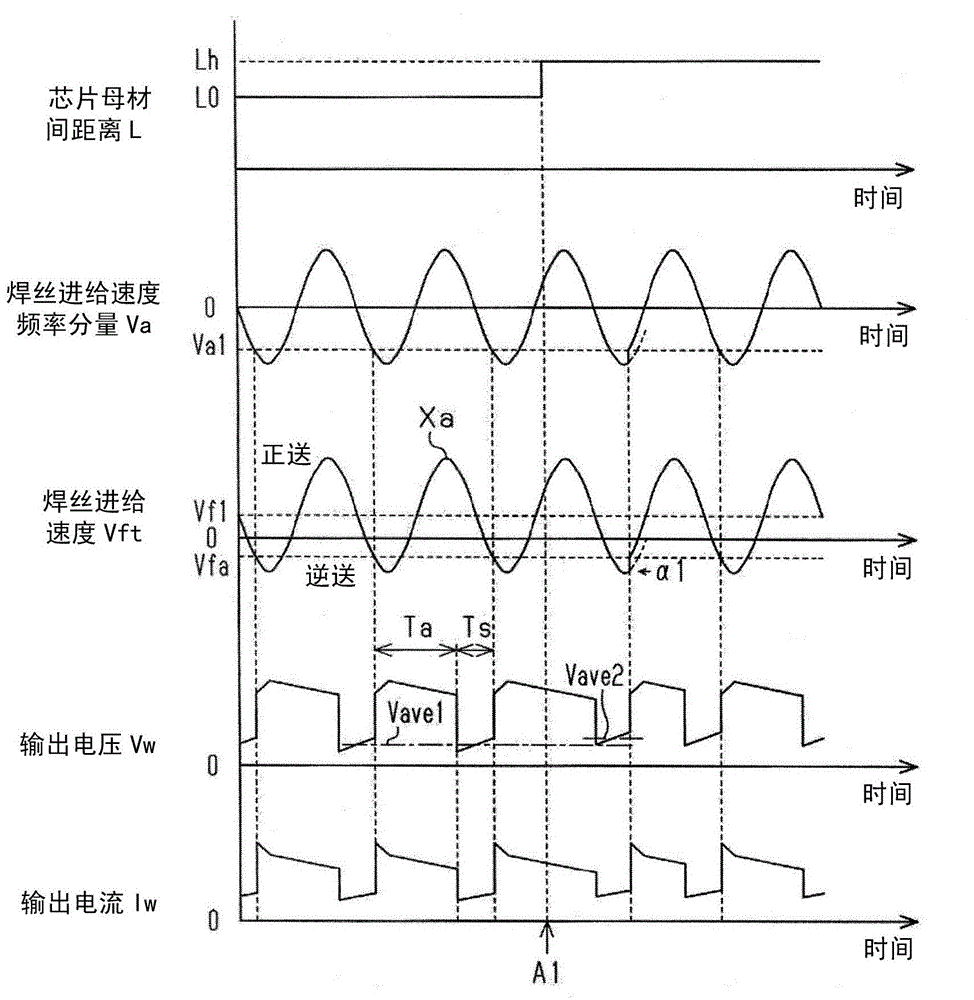

[0078] "When the distance L between chip base materials is elongated"

[0079] Such as Figure 4 As shown, when the average voltage of the output voltage Vw during the short-circuit period Ts exceeds the allowable range, for example, when it rises from Vave1 to Vave2, the out-of-synchronization determination unit 20d determines that the distance L betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com