Pressure swing adsorption gas production system and pressure swing adsorption gas production method

A technology of pressure swing adsorption and adsorption tower, which is applied in the field of pressure swing adsorption, which can solve the problems of long service life of adsorbents, inability to produce at the same time, large operating flexibility, etc., and achieve the effects of environmental friendliness, energy saving and process improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

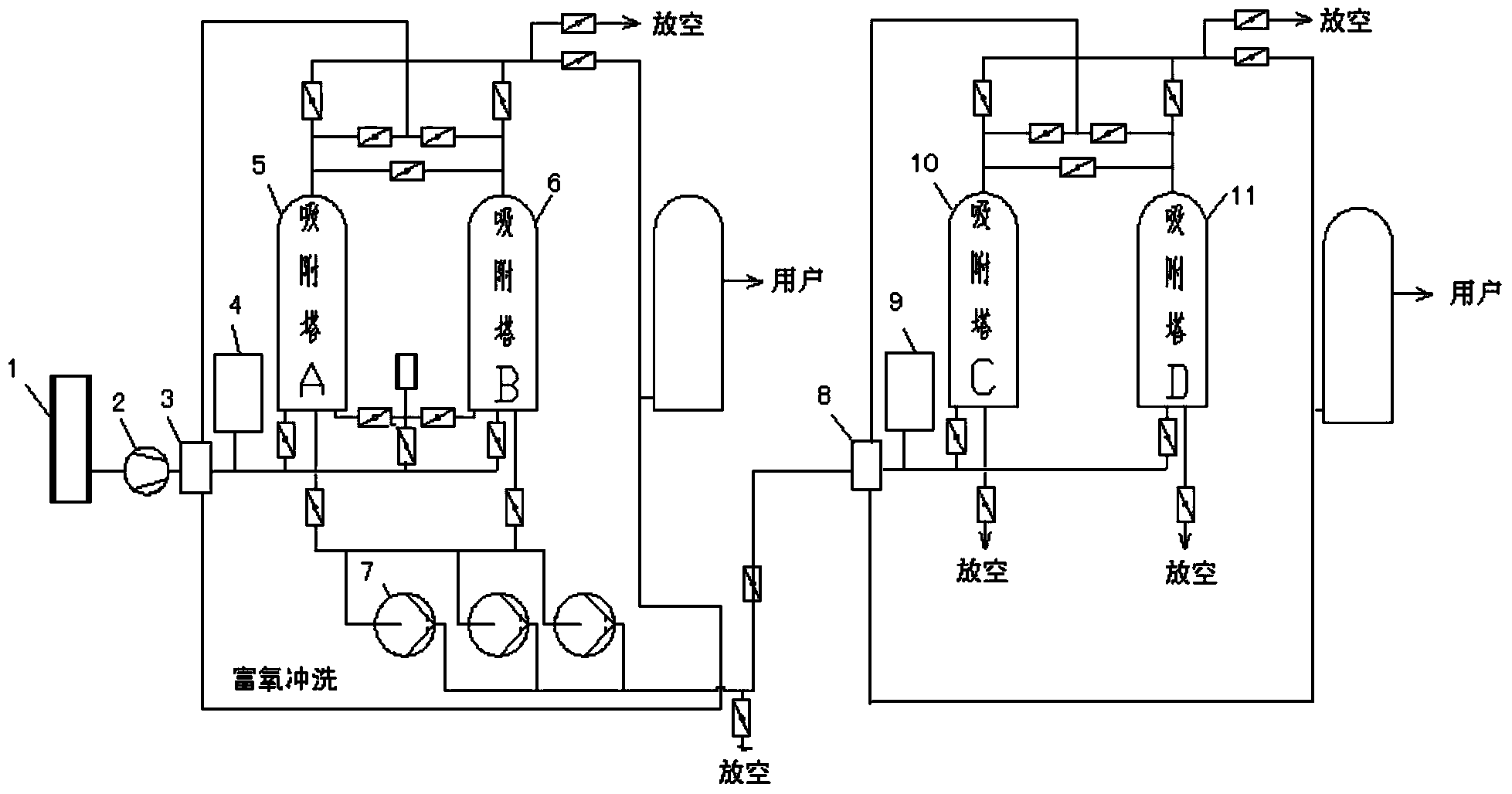

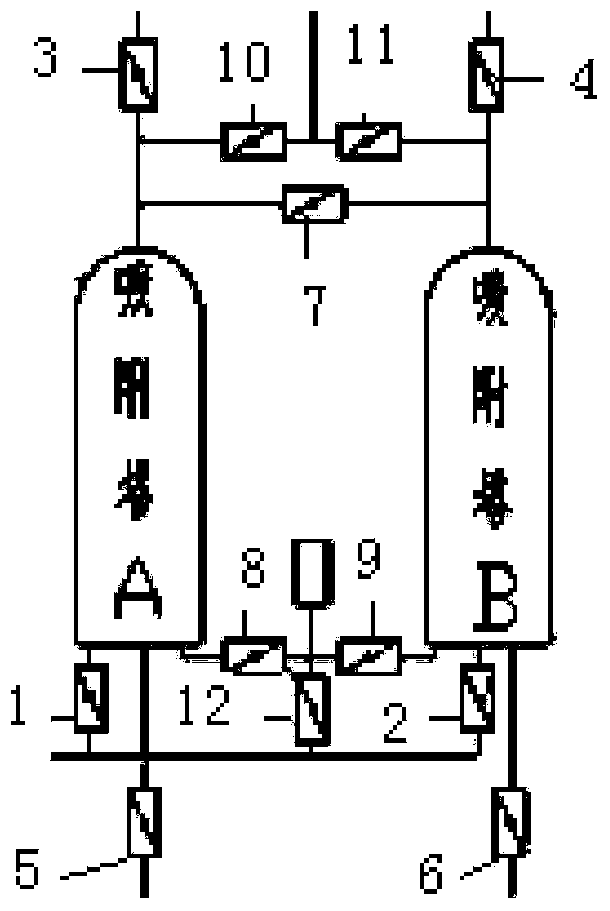

[0131] use figure 2 The pressure swing adsorption gas production system shown uses air as raw material to produce oxygen and nitrogen at the same time. For the settings of some valves, see image 3 For the process steps of oxygen production and the switch states of the valves, see Table 1. Table 1 is a list of process steps and valve switch states during pressure swing adsorption oxygen production in the embodiment of the present application.

[0132] Table 1 Table of process steps and valve switch status during pressure swing adsorption oxygen production in the embodiment of this application

[0133]

[0134]

[0135] Note: On means the valve is open, C means the valve is closed.

[0136] Step 1: Adsorption in adsorption tower A5, vacuuming in adsorption tower B6

[0137] Open the program-controlled valve into 1, out of 1, out of 1 (not in image 3 It is shown in , which is the vent valve of the first adsorption device) and true 2, close side 1 and uniform 1.

[0...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap