Side-pass optical fiber processing device and method of use thereof

A processing device, side-pass technology, applied in the field of side-pass optical fiber processing devices, can solve problems such as difficult air discharge, unfavorable development of enterprises, and influence on the efficiency and quality of D2 processing, achieving simple structure, low cost, Good large-scale production and use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

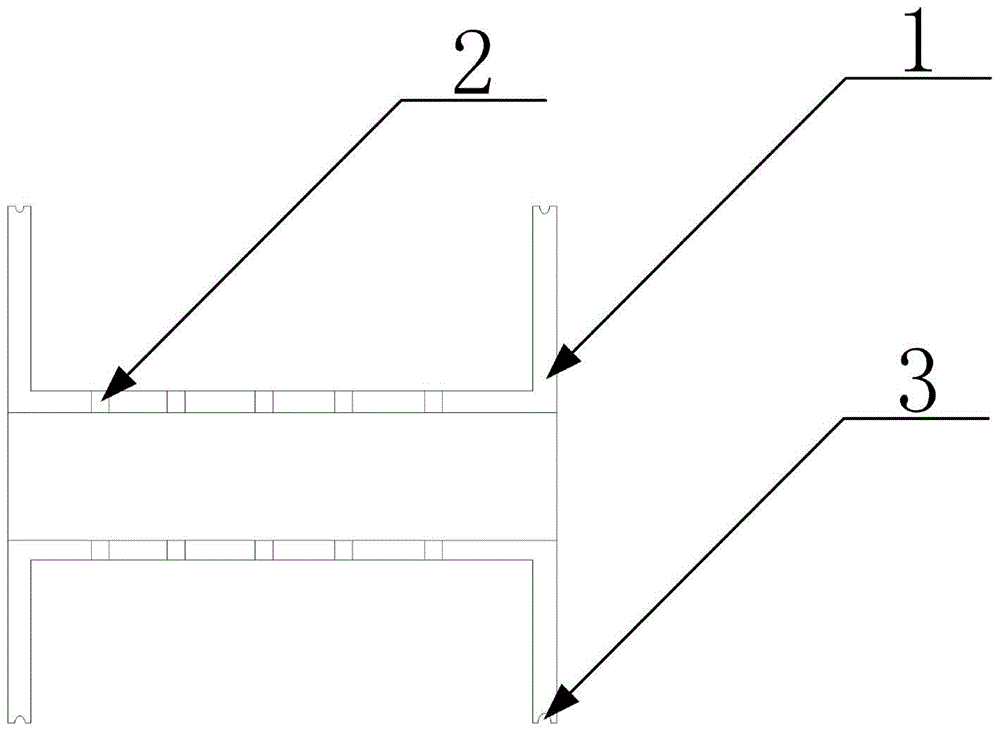

[0023] Such as figure 1 , 2 As shown in , 3, the side-pass optical fiber processing device includes a winding reel main body 1 and an air intake cover, and the winding reel main body 1 and the air intake cover are respectively provided with matching sealing structures.

[0024] A hollow central shaft is provided in the middle of the above-mentioned winding disc main body 1, and a ventilation hole 2 is provided on the central shaft, and an air outlet is also provided at the end of the central shaft. There are two air outlets, which are respectively arranged at two ends of the central axis.

[0025] Preferably, the ventilation holes 4 are arranged in arrays on the shaft wall of the central shaft.

[0026] The sealing structure on the above-mentioned winding disc main body 1 is a card groove 3 provided on its side wall. A sealing ring is also provided.

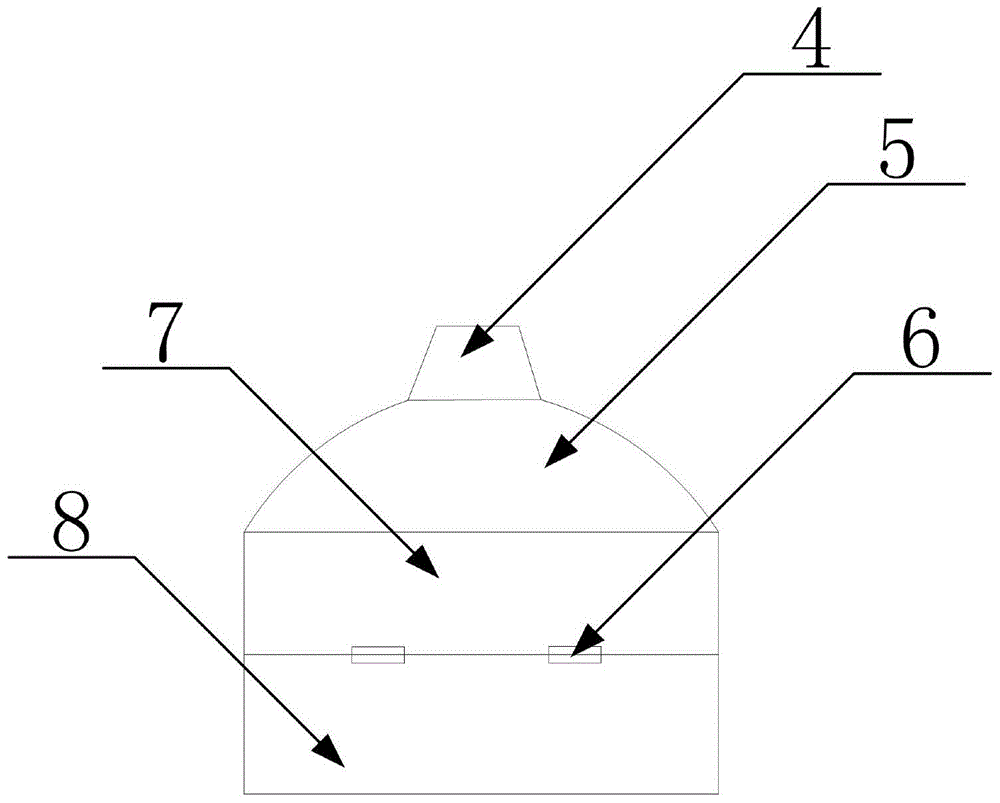

[0027] The air intake hood includes an air intake interface 4 , an air intake bucket 5 , a fixed wrapping barrel 7 and an o...

Embodiment 2

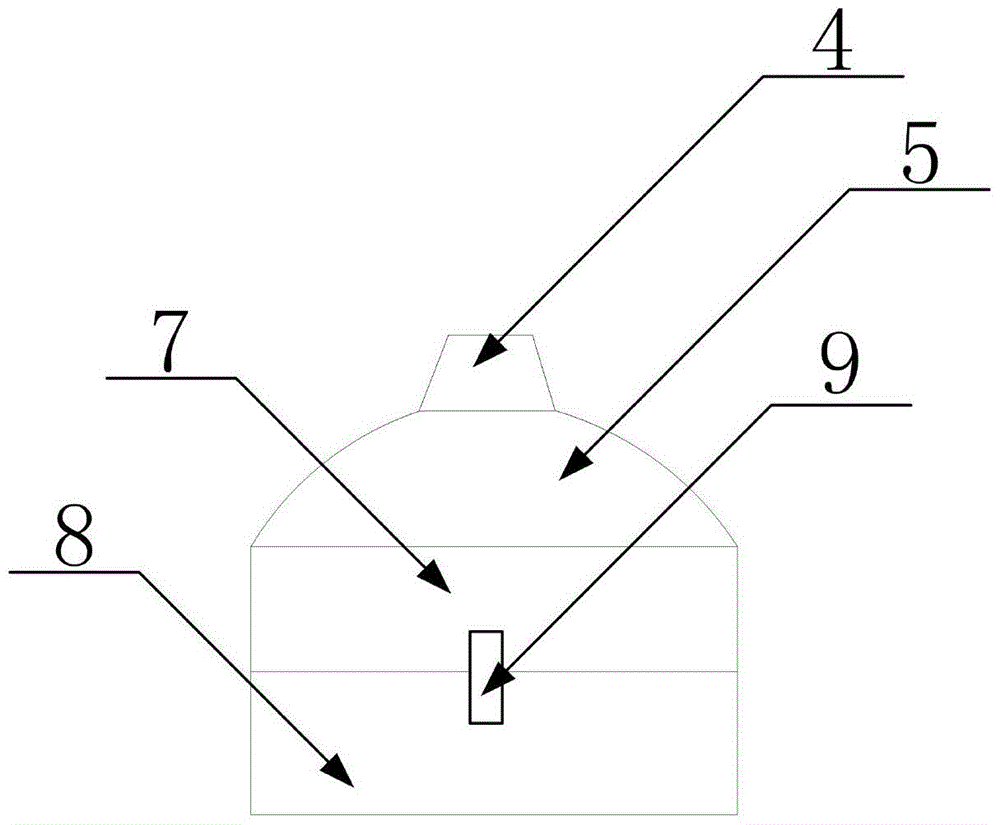

[0033] Such as Figure 4 As shown, the only difference between this embodiment and Embodiment 1 is that there is only one air outlet, which is arranged at any end of the central axis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com