Multi-ball setting shaft stop valve

A shut-off valve and wellbore technology, applied in wellbore/well valve device, sealing/packing, wellbore/well components, etc., can solve the problems of small flow area, early seating, poor stability, etc. Narrow space operation, simple and reasonable structure design, suitable for processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

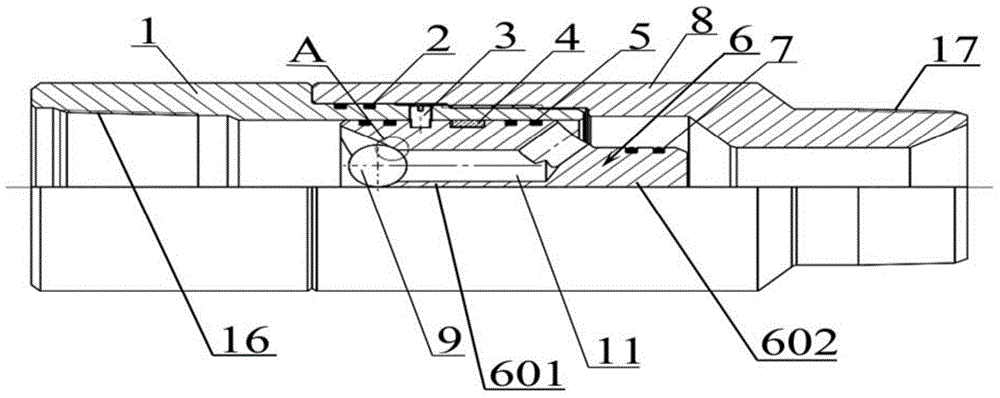

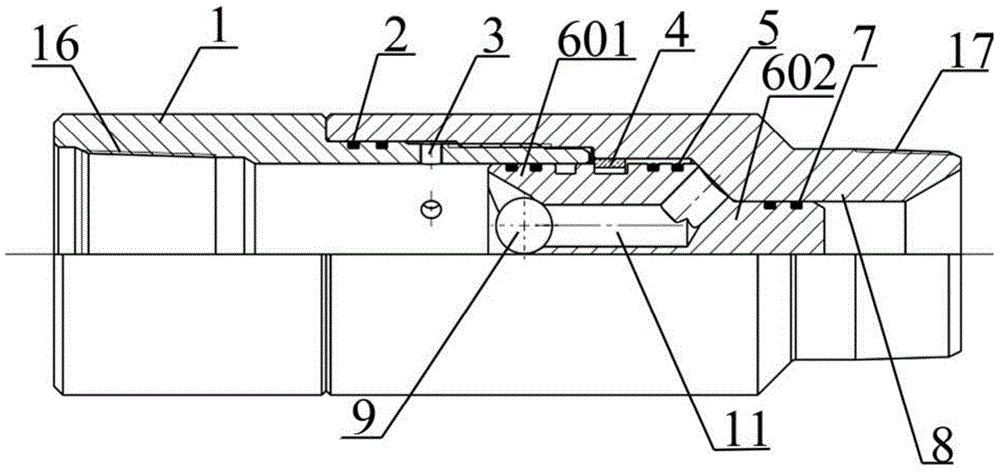

[0053] Embodiment 1 is based on the above-mentioned core idea, and the overcurrent channel is two specific technical solutions, which are combined below Figure 1 to Figure 5 The technical scheme with two overcurrent channels is described.

[0054] figure 1 It is an assembly drawing of a two-ball wellbore shut-off valve. Such as figure 1 As shown, a multi-ball seat sealing wellbore stop valve includes a valve body and a valve seat, the valve seat is located in the cavity of the valve body, and it slides and is seated in the valve body under the push of the fluid; wherein,

[0055] The valve body is formed by the detachable connection of the upper joint 1 and the lower joint 8, and the connection is sealed; It is sealed by setting two sealing rings a2 embedded in the outer surface of the upper joint 1;

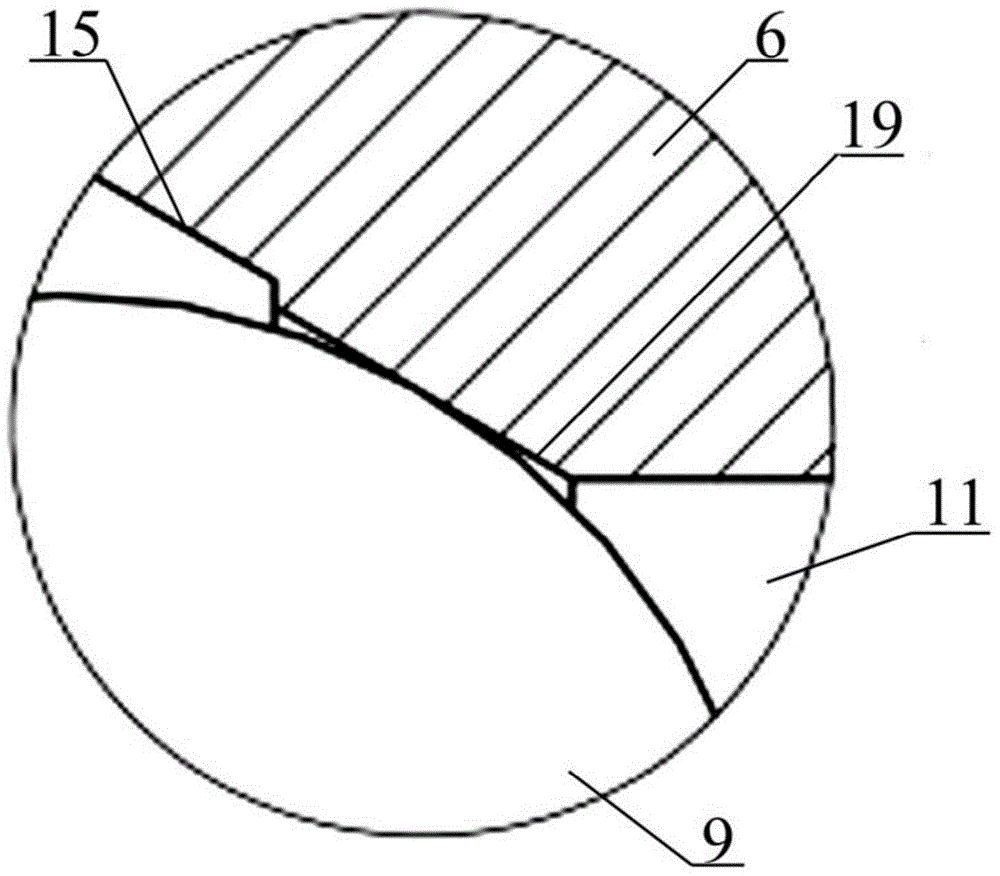

[0056] The valve seat is a piston 6; the piston 6 is provided with a through first flow passage 10 and a second flow passage 11, and the center line of the first flow passa...

Embodiment 2

[0075] Embodiment 2 is based on the above core idea, and the overcurrent channel is three specific technical solutions, which are combined below figure 2 , Figure 6 to Figure 10 The technical scheme with three overcurrent channels is described.

[0076] Such as Figure 6 As shown, a multi-ball seat sealing type wellbore stop valve includes a valve body and a valve seat, the valve seat is located in the cavity of the valve body, and is pushed by the fluid to slide and seat in the valve body, wherein, the The valve body is formed by the detachable connection of the upper joint 1 and the lower joint 8, and the joint is sealed;

[0077] The valve seat is a piston 6; the piston 6 is provided with three through flow passages, and the entrance of the flow passages has a transition part for low-density ball seat seal to provide boost;

[0078] see Figure 10 , the overcurrent channel includes a third overcurrent channel 25, a fourth overcurrent channel 35 and a fifth overcurrent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com