Multi-barrel cyclone desander and multi-barrel cyclone desanding method

A technology of desander and drum rotation, which is applied in the field of oilfield surface engineering produced fluid treatment, which can solve the problems of inability to adjust the treatment capacity, reduce the desanding efficiency, and unreasonable structure, so as to increase the number of high-efficiency working points and improve the desanding efficiency , the effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

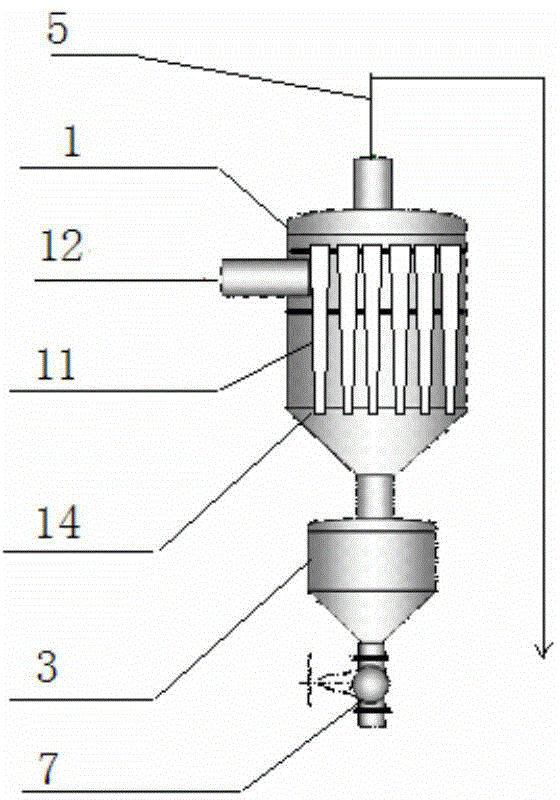

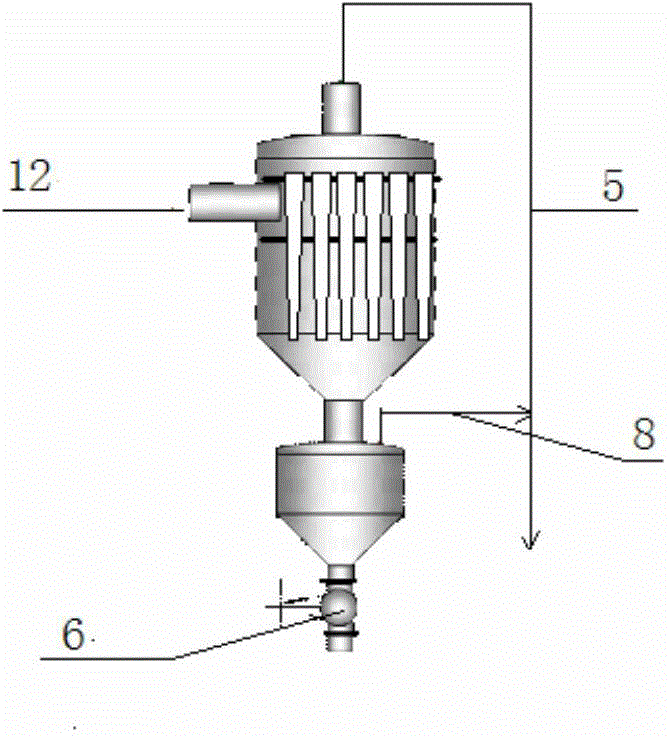

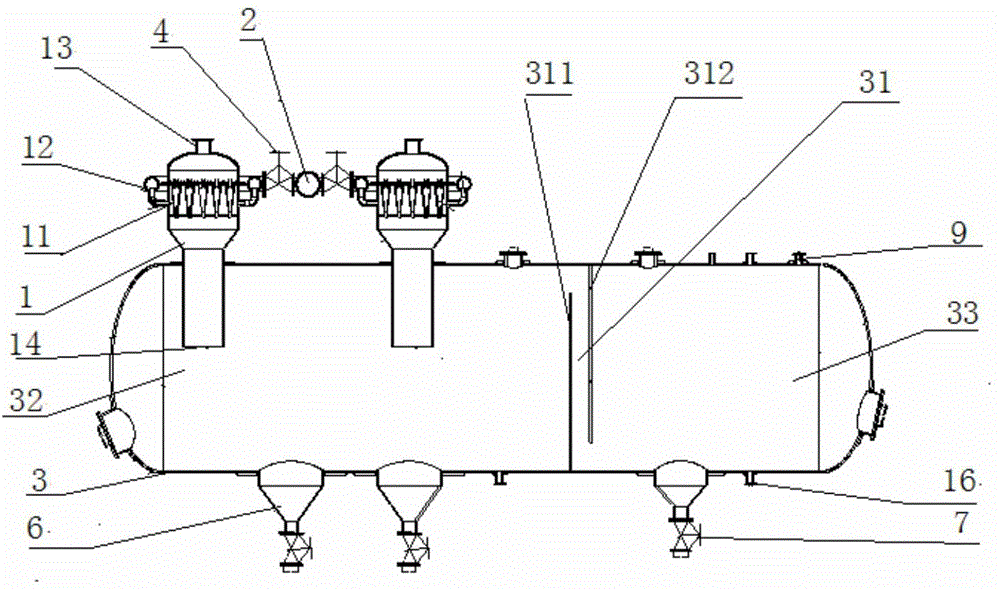

[0041] Such as Figure 1B As shown in the schematic diagram, by setting a drainage pipe on the top of the existing cyclone desander shell (i.e. sand collection cabin), a drainage and sand dragging mechanism is constructed to completely change the bottom flow of the current cyclone desander. The structure of the closed non-flow shell at the mouth realizes high-efficiency sand removal; the parallel connection of multiple cylinders realizes adjustable processing capacity and increases the number of efficient work points.

[0042] Based on the above pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap