Ventilating equipment for cleaning and maintenance of railway oil tanker

A technology for ventilation equipment and oil tank trucks, which is applied in the direction of mechanical equipment, machines/engines, non-volume pumps, etc. It can solve the problems of poor ventilation effect of blowers, poor mobility of blowers, energy saving and uneconomical costs, etc., and achieve ventilation operations Thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

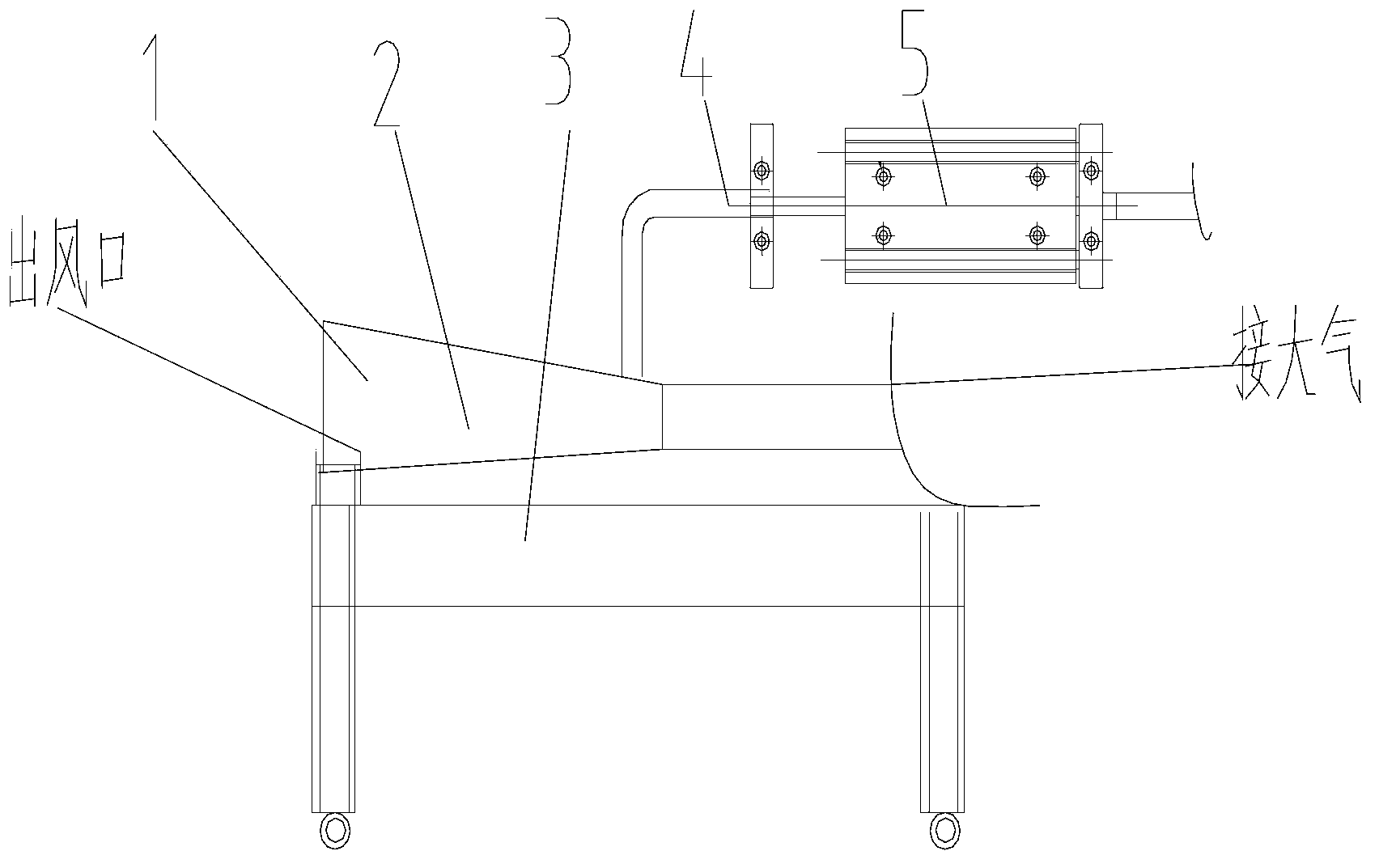

[0014] Example 1: Connection relationship

[0015] Venturi blower 1 and flexible air intake pipe 2 are all installed on movable support 3, and compressed air telescopic pipe 4 is connected with Venturi blower 1 and pneumatic booster pump 5. Venturi fan 1 is powered by the compressed air passing through the small nozzles on its metal base to drive or accelerate the air around the flexible intake pipe 2 to generate a strong moving airflow. A hose pushed by the compressed air line connects the air supply to the inlet nozzle on the side of the fan base. The Venturi blower 1 is connected with the compressed air telescopic pipe 4, has no driving power source, is portable and movable, and its outlet directly leads into the oil tanker, and the bases all have grounding wires. The flexible inlet pipe 2 is a flexible pipeline connected between the Venturi blower 1 and the atmosphere. Before the compressed air pipeline 6, the pneumatic booster pump 5 is used to increase the intake air...

Embodiment 2

[0016] Example 2: When it is necessary to ventilate the inside of the tank, the movable bracket 3 is pushed to the vicinity of the manhole of the tanker, the Venturi blower can be held by hand, the compressed air pipeline 6 is opened, and the atmosphere connected with the flexible air intake pipe 2 is brought into the tank. 3. Venturi blower blows into the oil tanker. When the pressure is insufficient or the required ventilation in the tank is large, the pneumatic booster pump can be turned on to increase the intake pressure and increase the exhaust air volume at the outlet.

[0017] The ventilation equipment can extend into the tank at will and change the wind outlet angle, so that there is no dead angle in the tank that is not easy to ventilate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com