Dust Cover Combination Body

A technology of dust cover and assembly, which is applied in the direction of springs, shock absorbers, spring/shock absorbers, etc., can solve the problems of dust cover damage, weight increase, and large-scale axial dimension, so as to improve durability, Reduce the effect of telescopic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

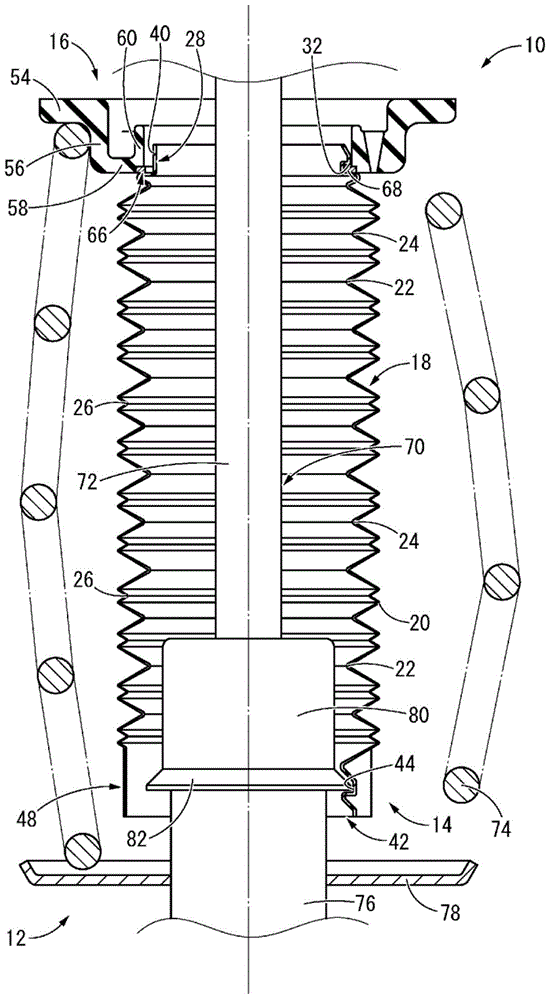

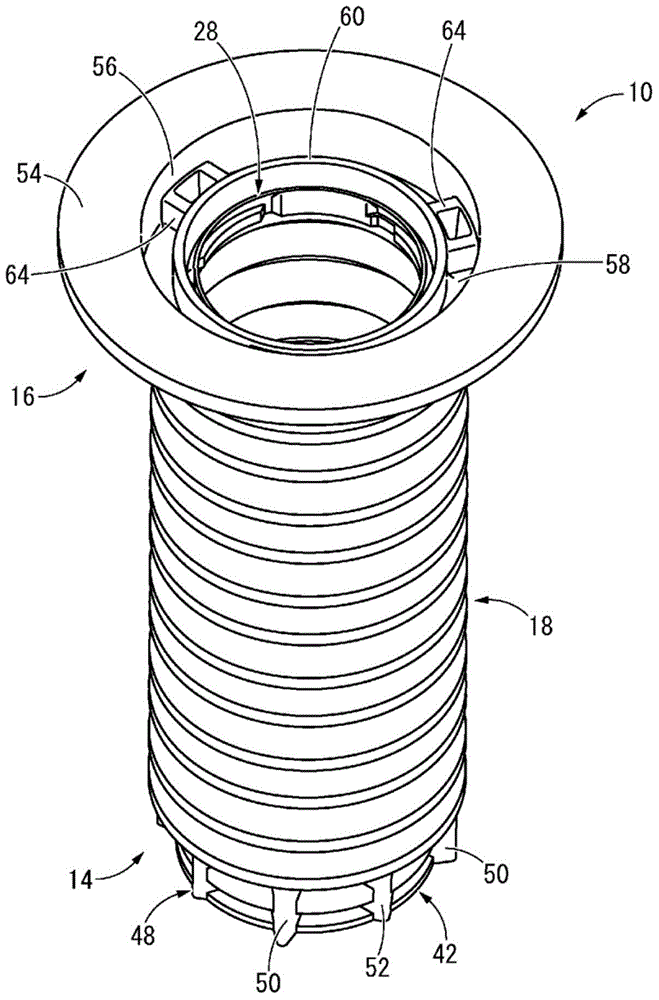

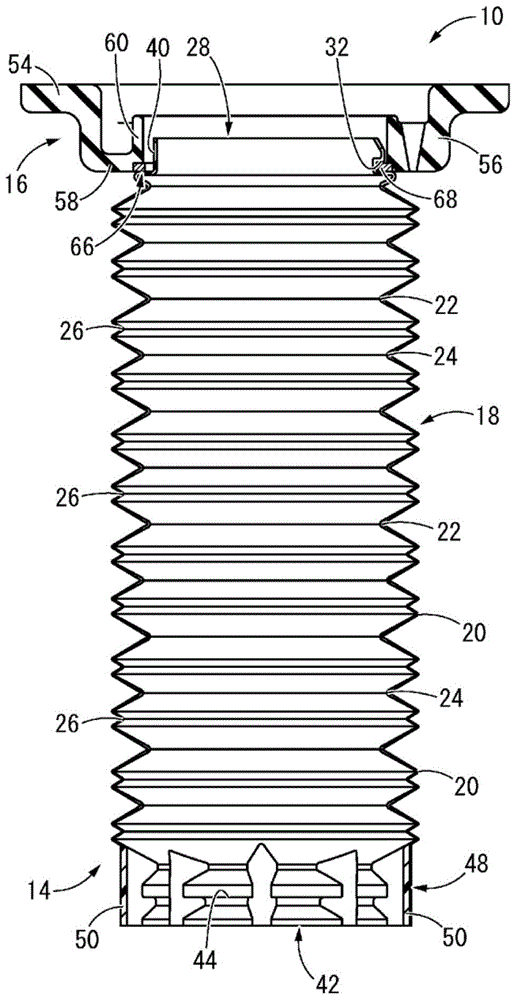

[0045] figure 1 The dust cover assembly 10 which is one embodiment of this invention is shown in the state attached to the suspension mechanism 12 of an automobile. like Figure 2 ~ Figure 4 As shown, the dust cover assembly 10 includes a dust cover 14 and an upper side spacer 16 . In addition, in the following description, the up-down direction means figure 1 in the up and down direction.

[0046] More specifically, the dust cover 14 is formed in a thin cylindrical shape as a whole, and is made of synthetic resin. The synthetic resin forming the dust cover 14 is not particularly limited, but in the present embodiment, for example, a material obtained by dispersing and mixing ethylene-propylene rubber (EPMD) in polypropylene (PP), which is a thermoplastic resin, is used. It has excellent weather resistance and formability. In particular, when forming the dust co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com