Engineering machinery air storage tank automatic drainage device and automatic drainage control method

A construction machinery and automatic drainage technology, which is applied in the field of construction machinery, can solve problems such as leakage of drainage and manual operation by personnel, and achieve the effects of eliminating leakage of drainage, ensuring timeliness, and improving stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation will be described below in conjunction with the accompanying drawings.

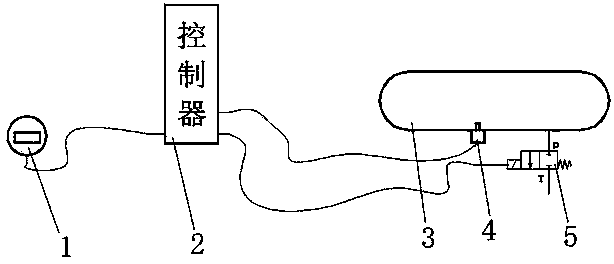

[0017] Such as figure 1 As shown, the automatic drainage device of the construction machinery air storage tank includes an air storage tank 3, a controller 2, a machine working time collector 1 and an air humidity sensor 4, and an electromagnetic valve 5 is arranged on the air storage tank, and the electromagnetic valve 5 is Two-position two-way valve, the inlet P port of the valve is connected to the drain port of the gas storage tank 3, the outlet T port of the valve is connected to the atmosphere, the normal position of the solenoid valve is the cut-off position, no drainage; after triggering, it is the working position, and the The water in the air tank is vented to the atmosphere. The air humidity sensor 4 is arranged on the air storage tank to detect the humidity of the air in the air storage tank, and transmits the collected humidity signal to the controller 2 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com