Backlight Module

A backlight module and light edge technology, which is applied in the field of backlight modules, can solve the problems of incomplete sealing, chromatic aberration at the edge position of the optical film 16, leakage, etc., and achieve the effect of improving the edge chromatic aberration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Before the present invention is described in detail, it should be noted that in the following description, similar components are represented by the same numbers.

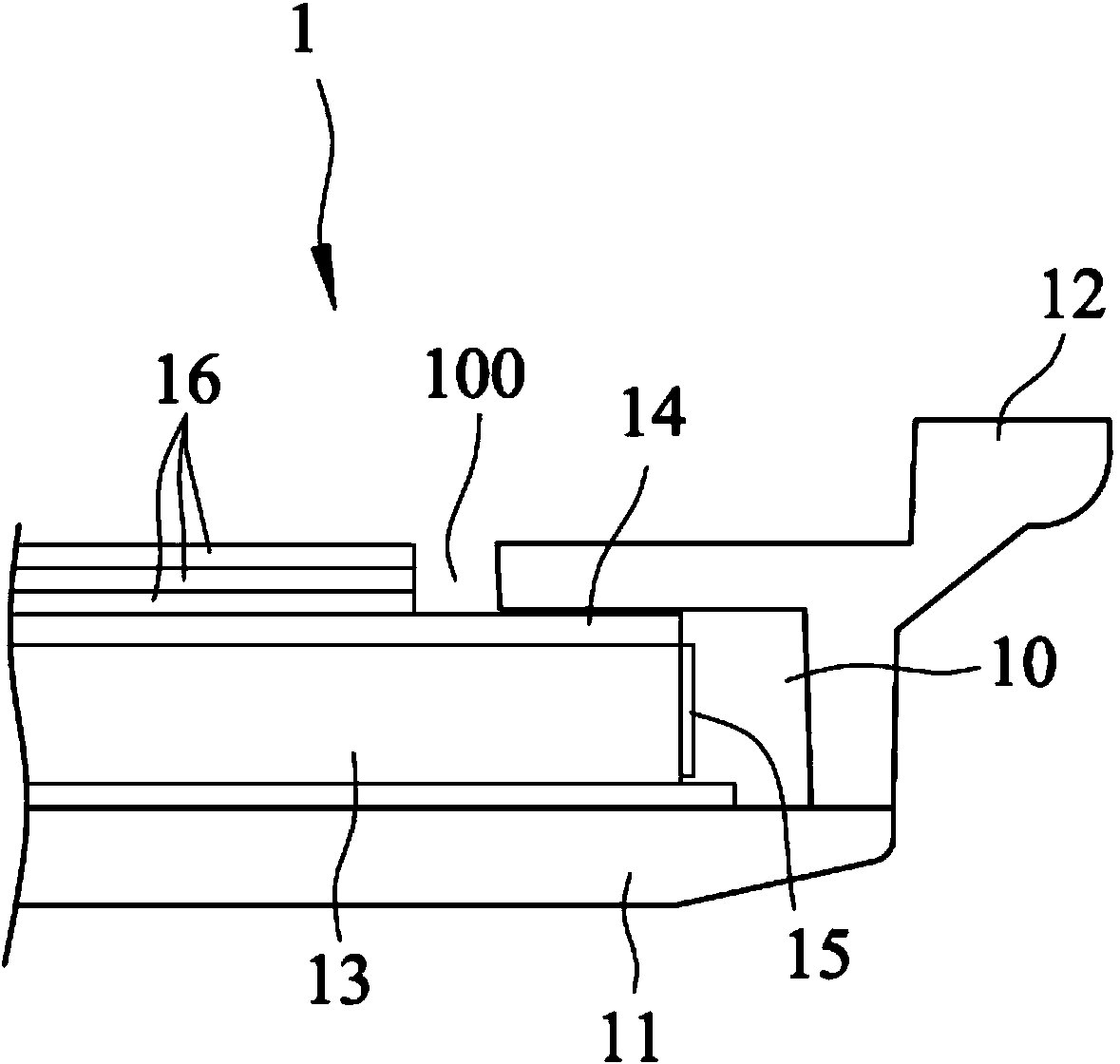

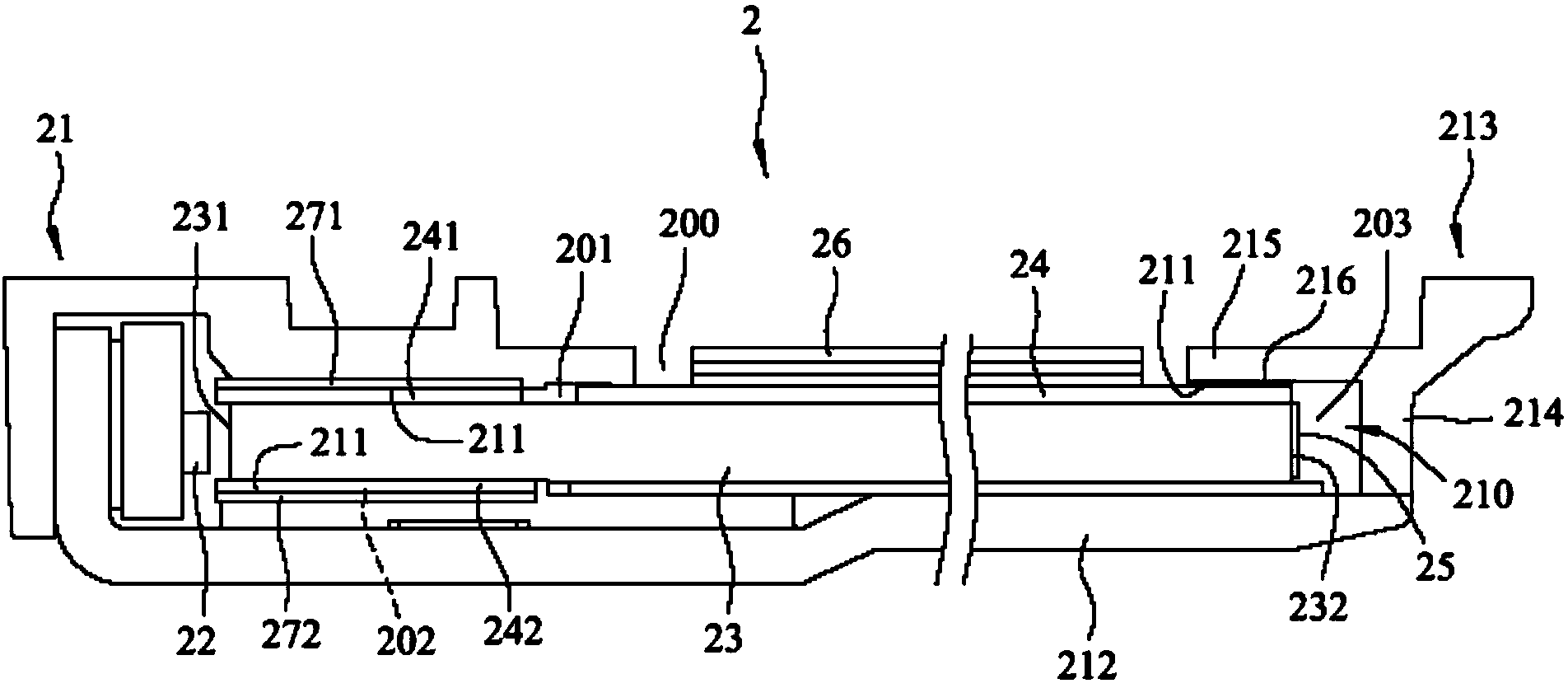

[0024] Refer to figure 2 versus image 3 , The first preferred embodiment of the backlight module 2 of the present invention includes a housing unit 21 having at least one reflective surface 211 and surrounding an accommodating space 210, a light source 22 disposed in the accommodating space 210, and an installation A light guide plate 23 in the accommodating space 210, a quantum dot enhancement film 24 stacked on the light guide plate 23 and located in the accommodating space 210, a reflector 25 arranged on the edge of the light guide plate 23, And an optical unit 26 stacked on the quantum dot enhancement film 24. The light guide plate 23 includes a light incident side 231 facing the light source 22, and a surrounding side 232 connected with the light incident side 231 and forming the edge of the light guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com