Particle collection and detection system

A detection system and particle technology, applied in particle and sedimentation analysis, measuring device, particle size analysis, etc., can solve the problems of low production efficiency, high labor intensity of workers, low yield of finished products, etc., and achieve simple structure, compact structure and simple composition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

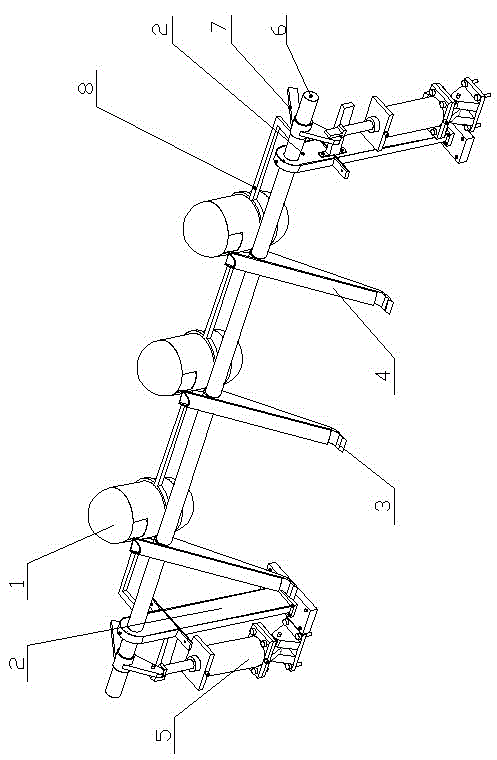

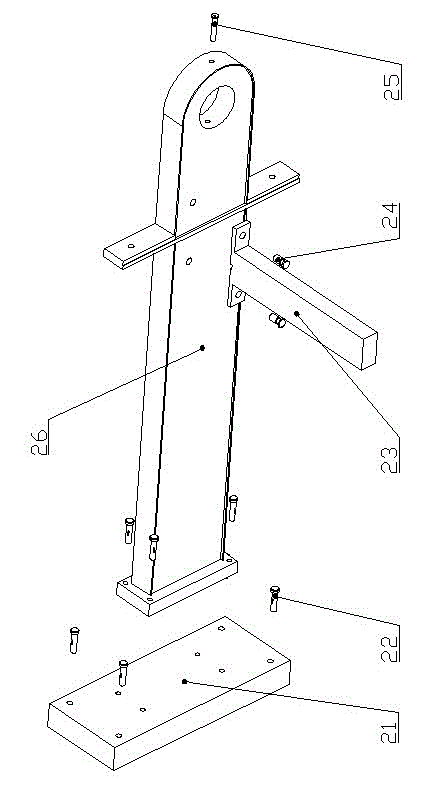

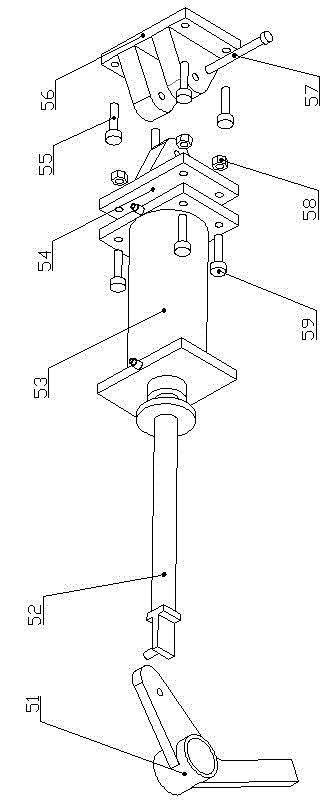

[0017] A particle collection and detection system, including a fixed base frame and a pneumatic drive device installed in the drum of an automatic granulator. The fixed base frame is provided with a support shaft, and the support shaft is provided with a box fixing frame. There is at least one sampling box, a sampling handle is provided on the support shaft, the sampling handle corresponds to the position of the sampling box, a sample guide tube is welded on the sampling handle, and the rotation of the support shaft drives the sampling handle and the sample guide tube to move, To realize the sampling of particles, a particle collection device camera and a particle cleaning device are installed in the lighting box. combine figure 1 , figure 2 , its fixed base frame 2 comprises fixed base plate 21, main support frame 26, screw I22, screw II24, travel switch 23, lubricating screw 25; Wherein fixed base plate 21 is fixedly connected with automatic granulator by screw I22, main s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com