Automatic film stacking machine

A stacking machine and coating technology, which is applied in battery assembly machines, winding/folding electrodes, sustainable manufacturing/processing, etc., can solve problems such as easy unwinding and poor coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

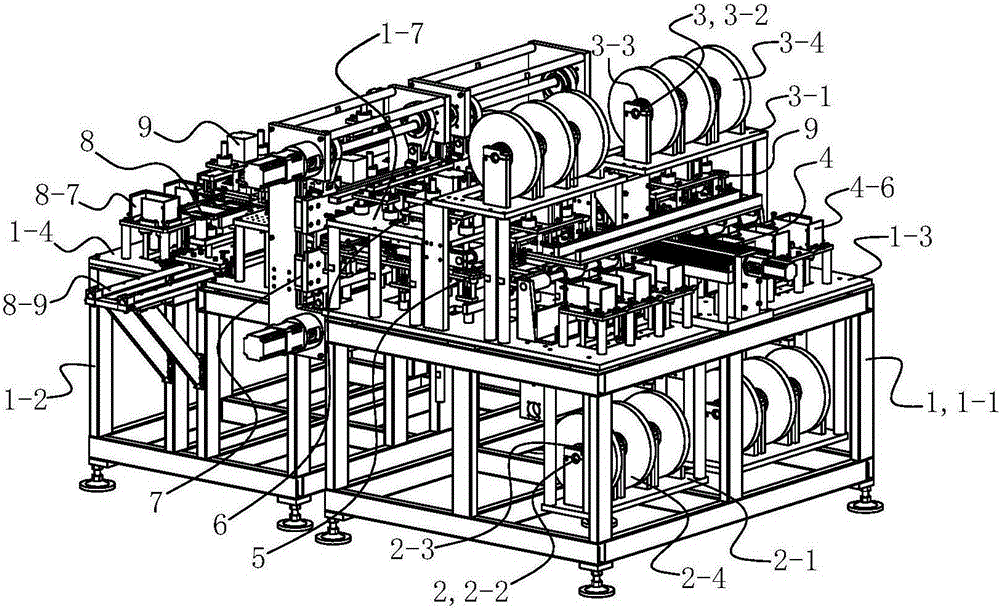

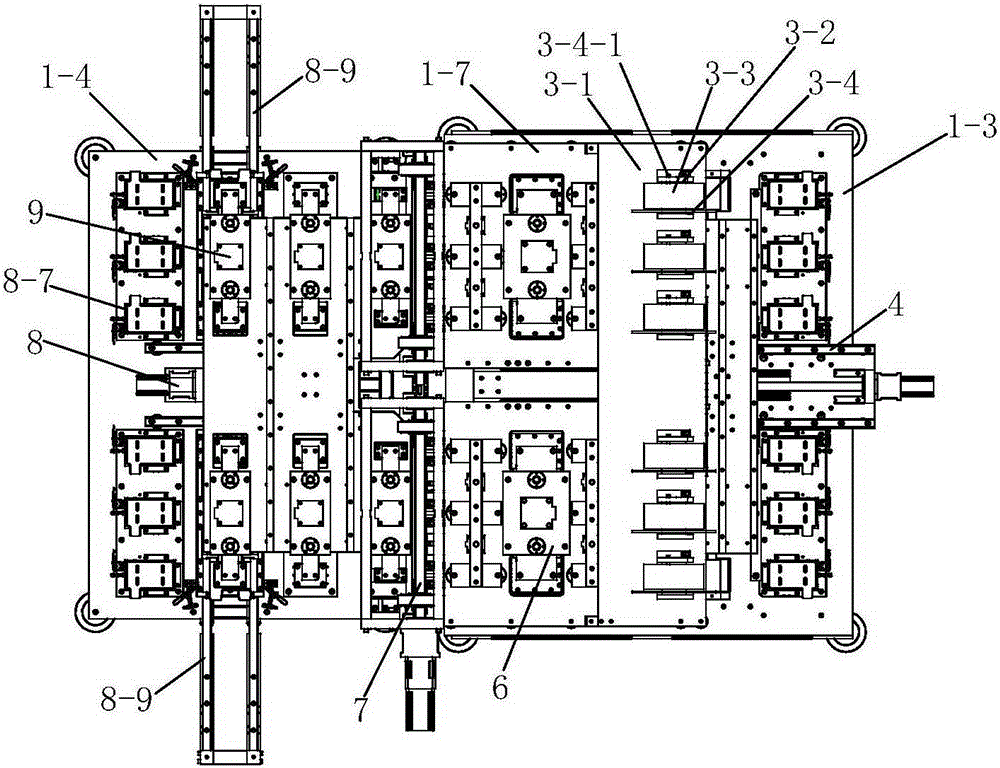

[0081] The automatic film stacking machine of the present embodiment, as figure 1 and figure 2 As shown, it includes a frame 1, a lower diaphragm unwinding device 2, an upper diaphragm unwinding device 3, a sheet feeding device 4, a sheet transferring device 5, a sealing pressing device 6, a shearing device 7 and a stacking device 8.

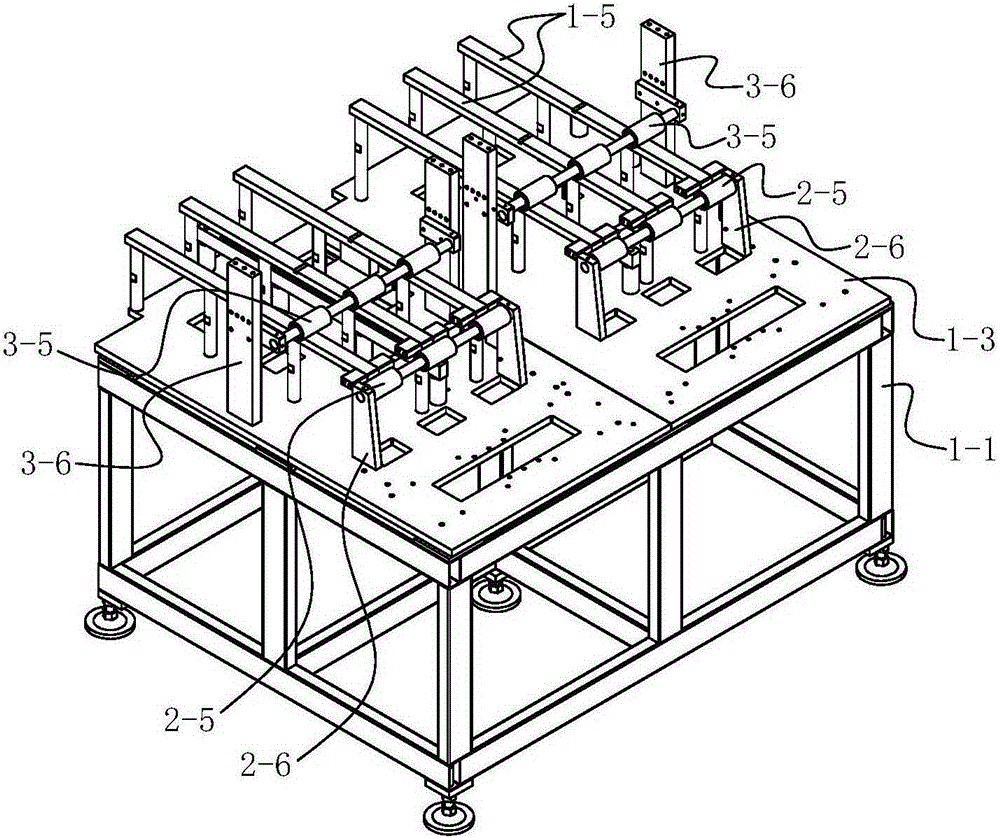

[0082] Such as Figure 1 to Figure 3 As shown, the frame 1 includes a coating frame 1-1 and a lamination frame 1-2 arranged adjacently, and the coating frame 1-1 is located in front of the lamination frame 1-2. The lower diaphragm unwinding device 2, the upper diaphragm unwinding device 3, the film feeding device 4, the film moving device 5 and the sealing pressure device 6 are arranged on the coating frame 1-1. The lamination device 8 is located on the lamination frame 1-2. The shearing device 7 is arranged on the coating frame 1-1 and between the stacking frame 1-2. The sheet transfer device 5 is located behind the sheet feeding device 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com