Device and method for discharging products, particularly product containers such as bottles

A technology of unloader and product, which is applied in the field of devices for container products such as bottles, which can solve the problems of high unloading speed, entering pause time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The unloading of products, in particular container products such as bottles, is done by means of an unloading device having one or more unloading sections.

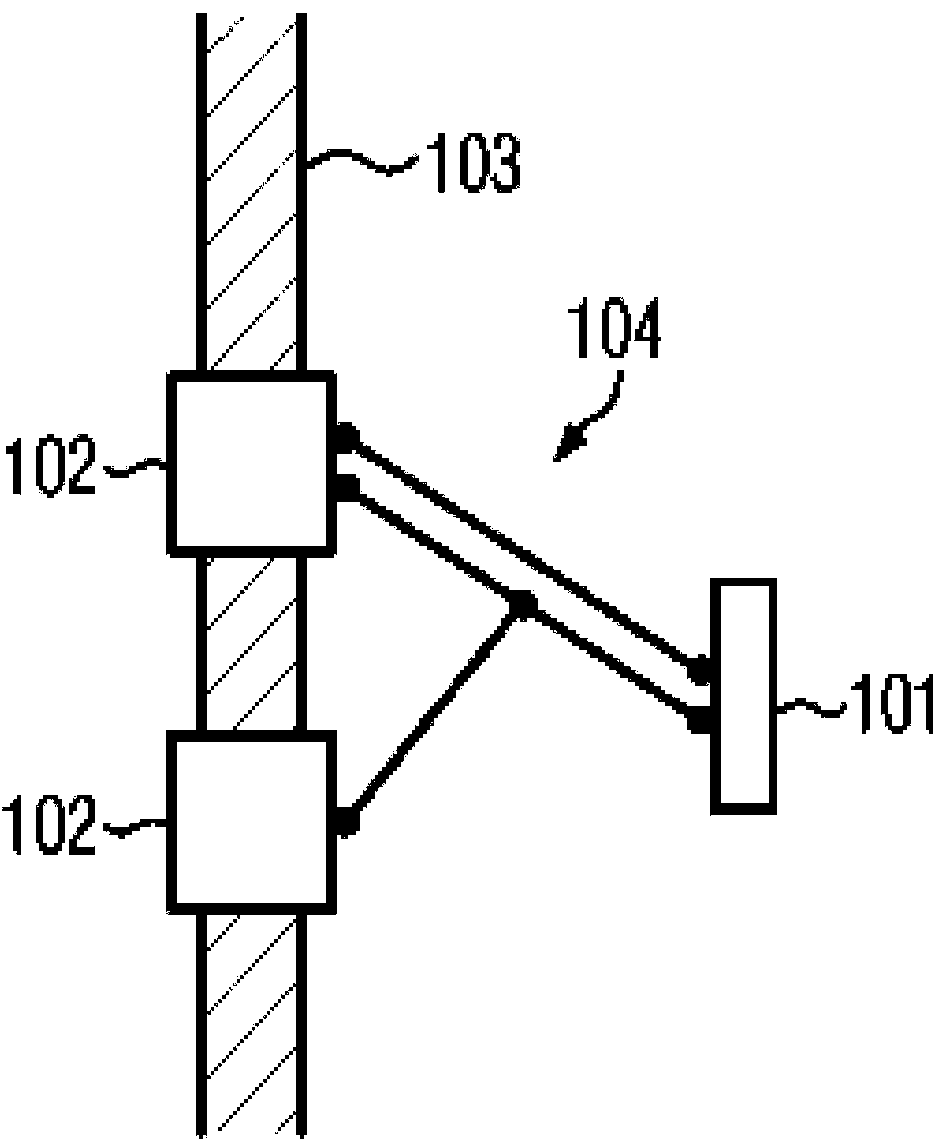

[0031] figure 1 The unloading section 104 on the corresponding guide rail 103 is schematically illustrated. The connection between the unloading section 104 and the guide rail 103 is realized by two carriages 102 connected to the guide rail 103 . In addition to said carriage 102, the unloading section 104 comprises an unloader 101 enabling product unloading by physical contact. By changing the relative distance of the carriages 102 to each other, the products to be unloaded can be unloaded by changing the offset of the unloader 101 . A change in the relative position of the carriage 102 on the rail 103 can be produced by changing the relative speed of the carriage. Here, the speed of one or both carriages 102 is changed for a limited time, so that the resulting speed difference between the two carriages within a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com