Mechanical coolant pump

A coolant pump, mechanical technology, applied in engine cooling, coolant flow control, mechanical equipment, etc., can solve problems such as high actuation power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

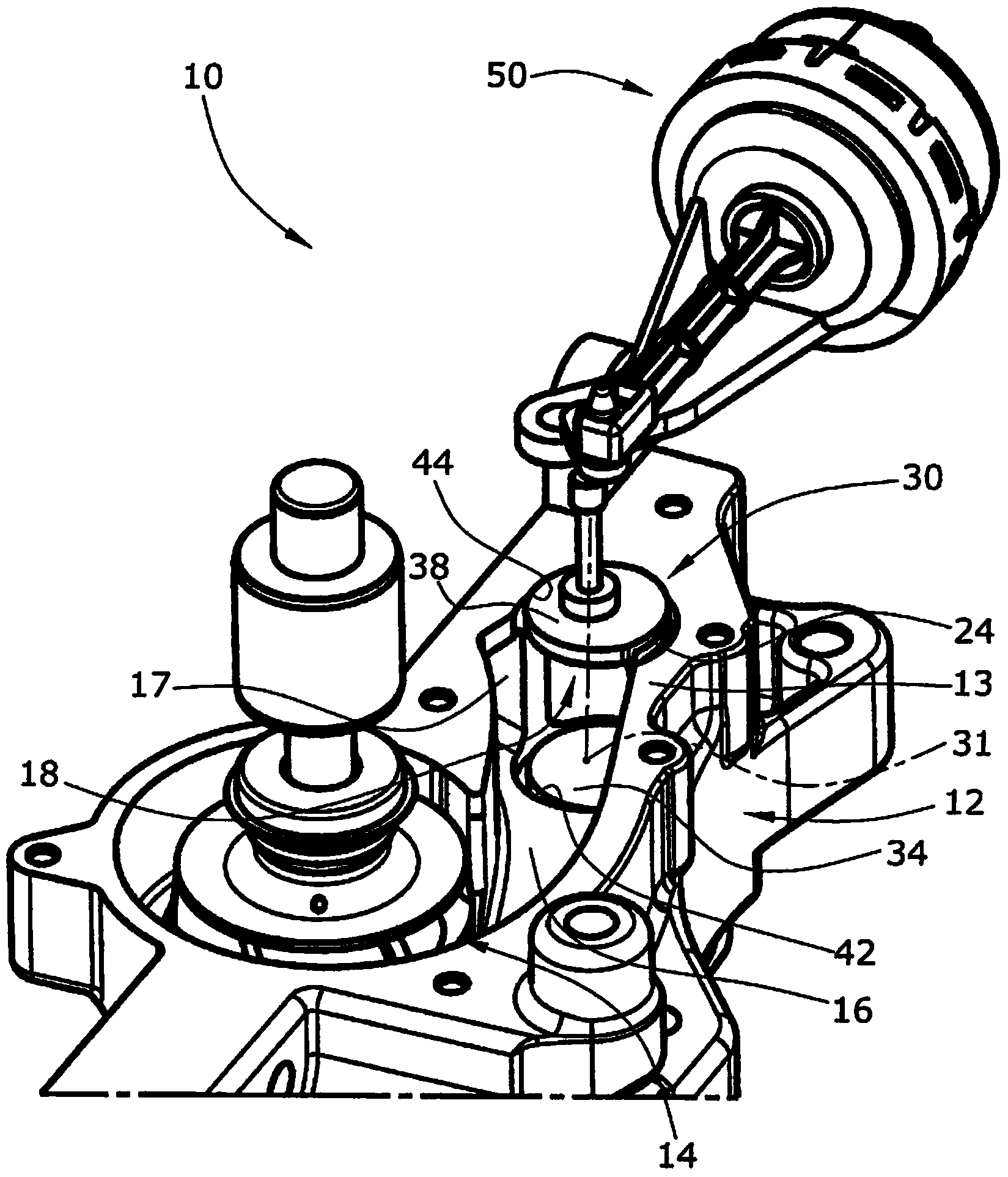

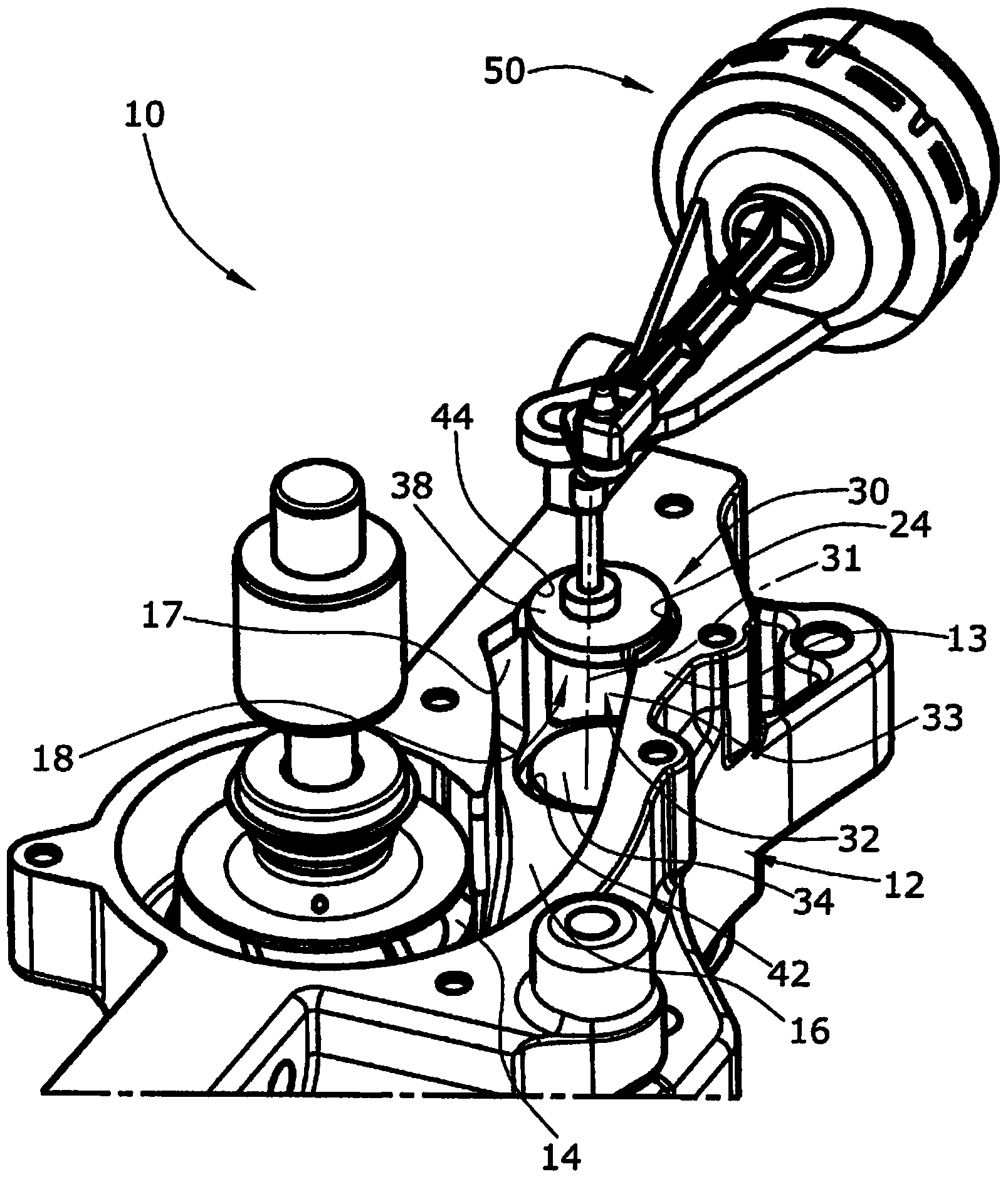

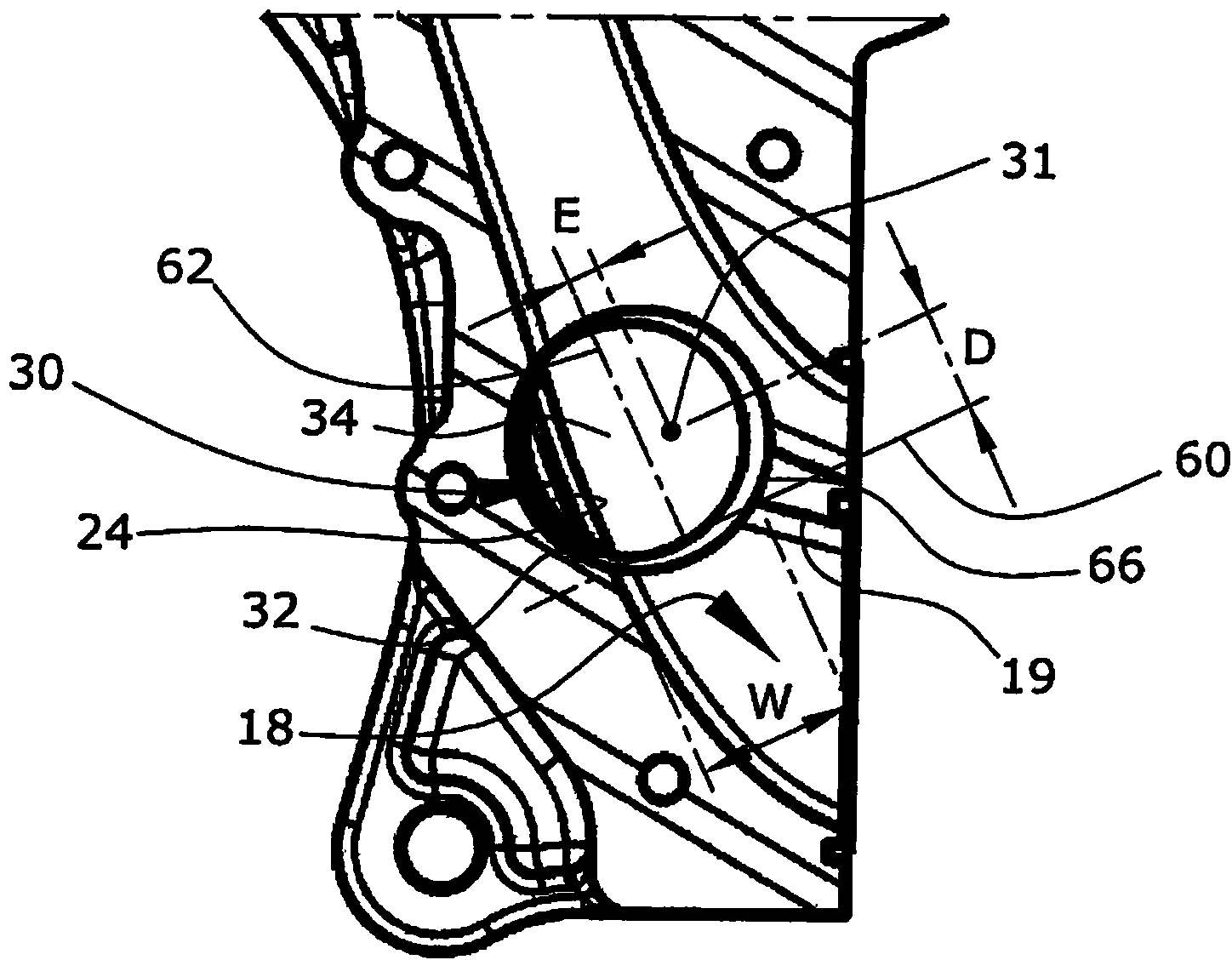

[0022] Figures 1 to 6 A mechanical coolant pump 10 for circulating coolant for an internal combustion engine is shown. The coolant pump 10 can be mounted directly to the engine block of the internal combustion engine. The coolant pump 10 is provided with a drive wheel (not shown) which can be driven by a drive belt directly driven by the internal combustion engine. The rotational speed of the coolant pump 10 is proportional to the rotational speed of the internal combustion engine.

[0023] The coolant pump 10 is provided with a pump housing 12 which houses an impeller pump wheel 14 which radially pumps liquid coolant introduced in the axial direction into an outlet volute 16 . The outlet volute 16 is defined by the volute 13 which is part of the pump casing 12 . The axial coolant pump inlet is provided on the bottom side of the coolant pump 10, as figure 1 and 2 shown in .

[0024] The outlet volute 16 comprises a first outlet channel 18 and a second outlet channel 17 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com