Coolant circuit of an internal combustion engine, and compensating vessel designed for said coolant circuit

A technology of balancing container and coolant, applied in the direction of engine cooling, machine/engine, mechanical equipment, etc., to avoid foaming and prevent vortex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

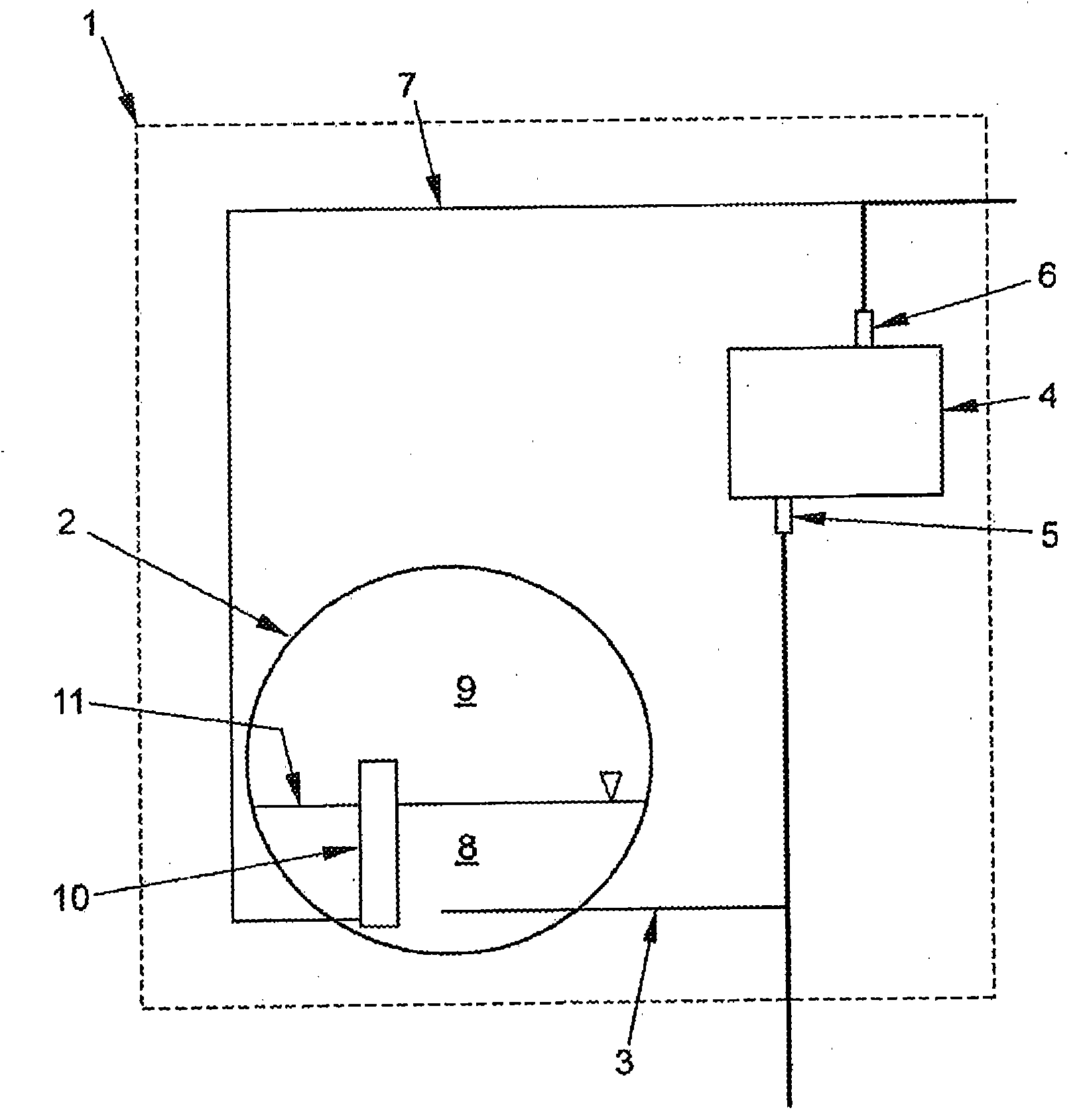

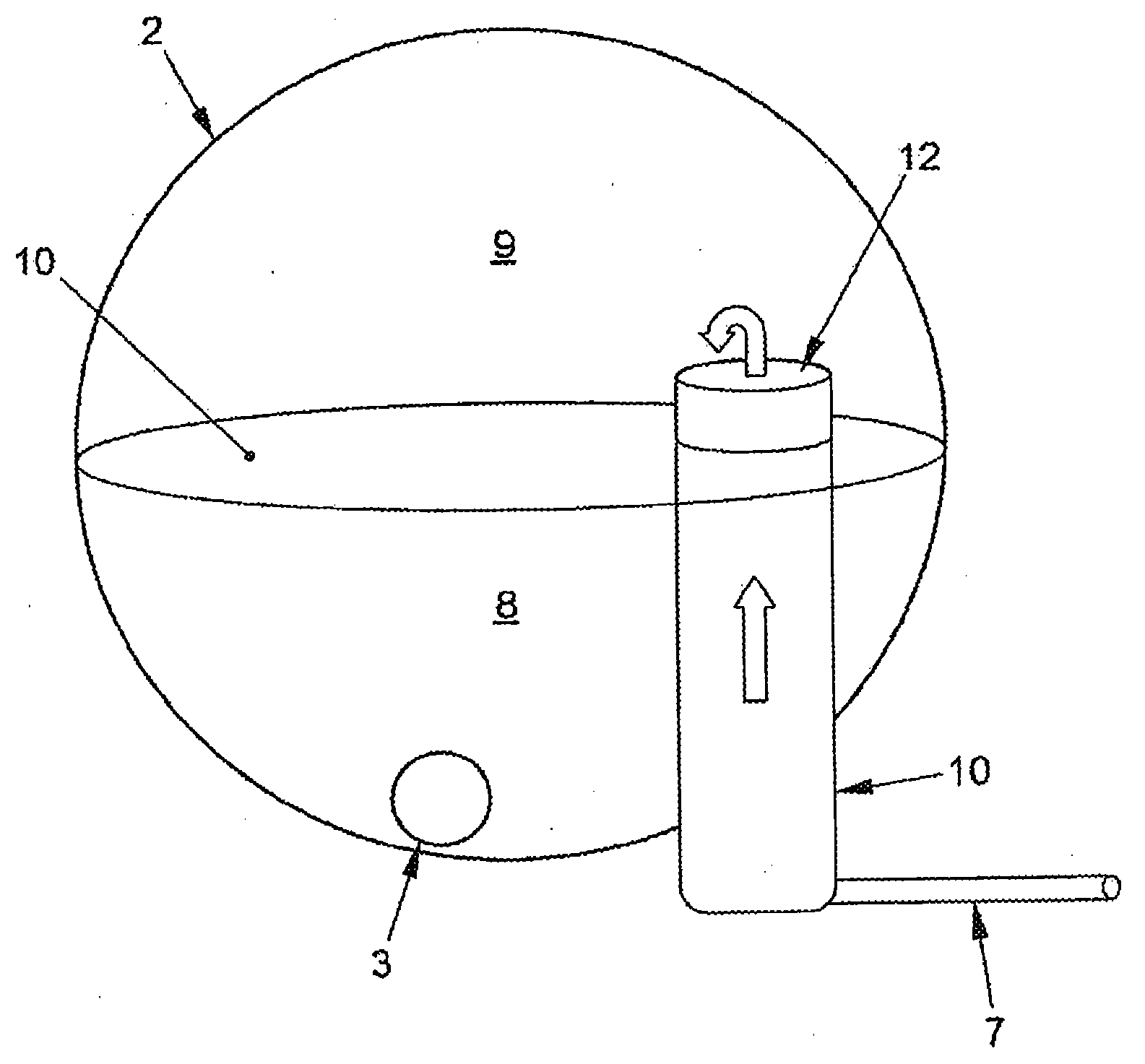

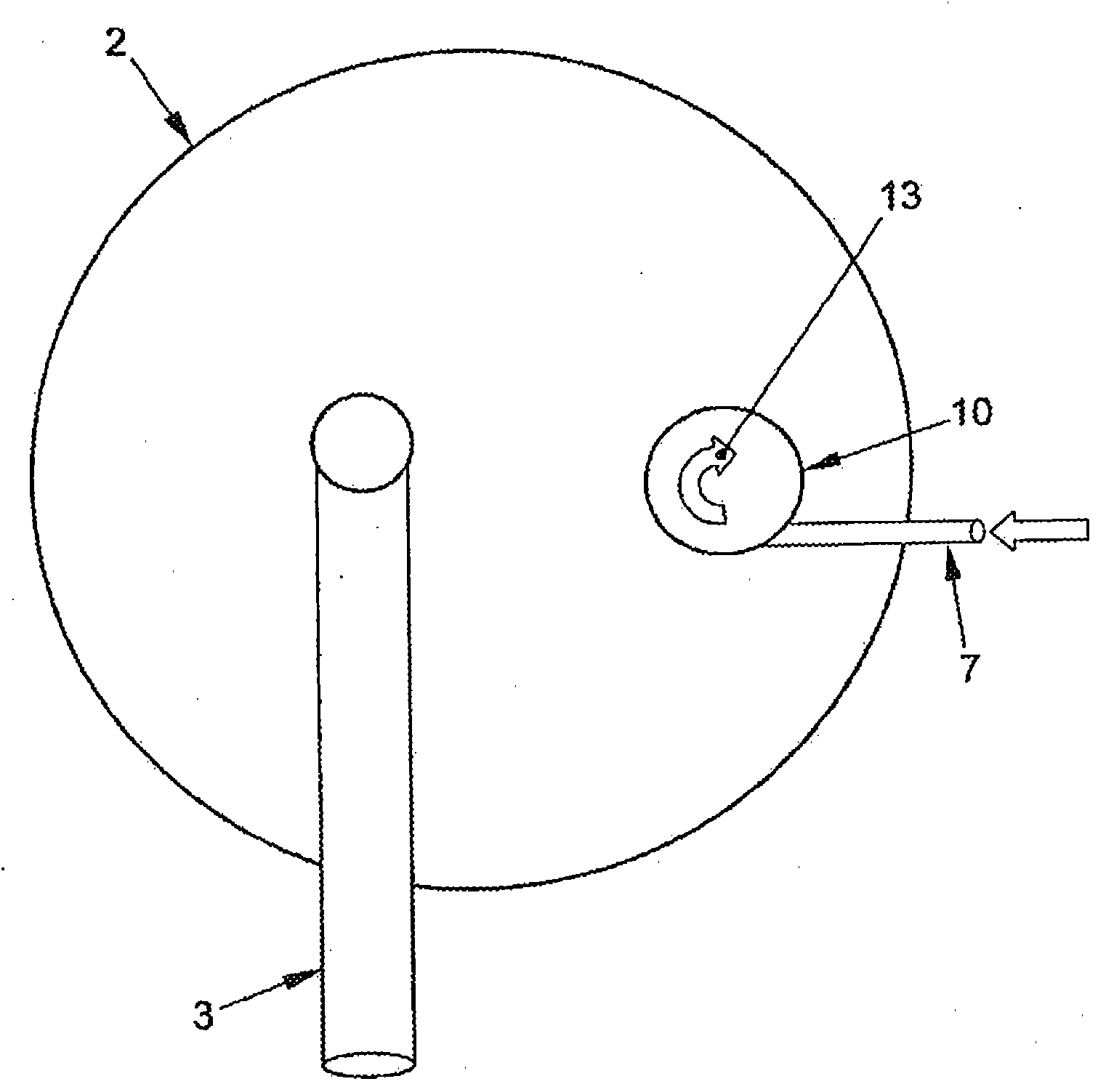

[0028] The following is based on Figures 1 to 3 The coolant circuit 1 according to the invention of the internal combustion engine (not shown) and the compensating container 2 included in the coolant circuit 1 will now be explained in more detail. The balancing container 2 is connected via a supply line 3 for the coolant to a heat exchanger 4 of the charge air cooler. The coolant passes through the supply line 3 through the inlet opening 5 into the heat exchanger 4 . In the upper region of the heat exchanger 4 there is a discharge hole 6 for the coolant with a branch, through which on the one hand the main volume flow is conveyed into the low-temperature region (not shown) and on the other hand through which the secondary volume flow is passed. It is led back into the equalization container 2 via the ventilation line 7 . The special properties of the ventilation line 7 here are the higher flow velocities occurring therein due to the smaller cross-sectional area in the venti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com