Motor winding stripping method

A motor and winding technology, which is applied in the field of insulating film peeling, can solve the problems of deterioration of motor defect rate and deterioration of welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

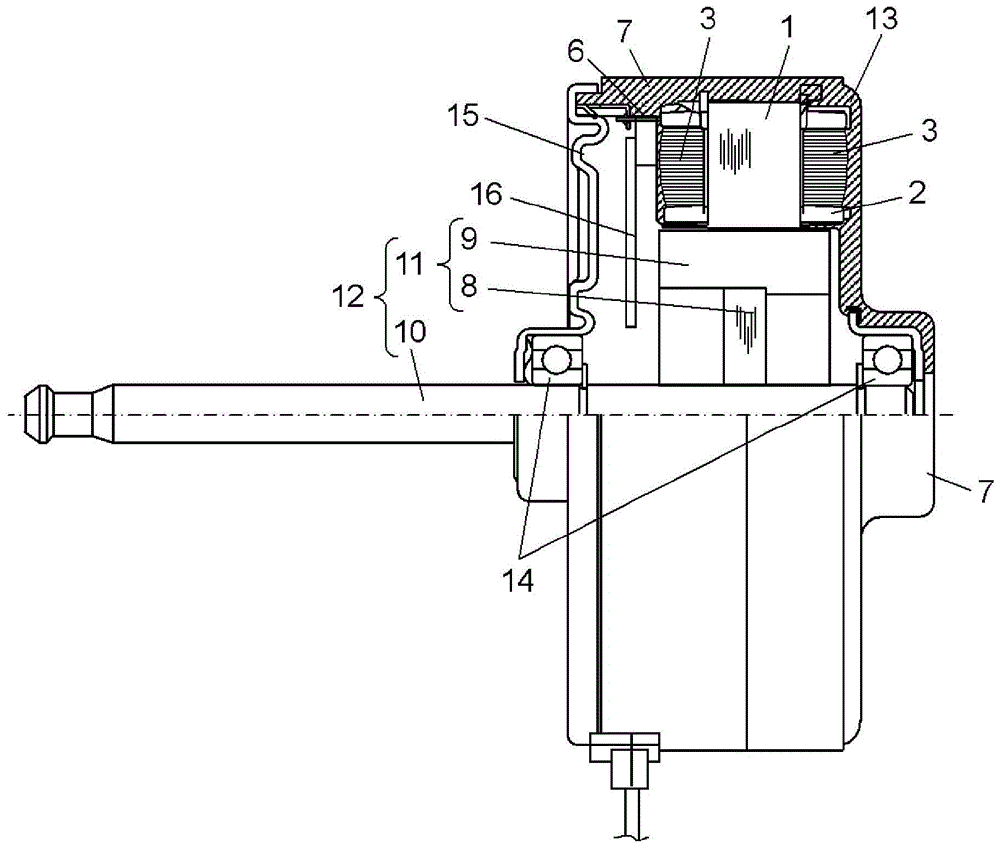

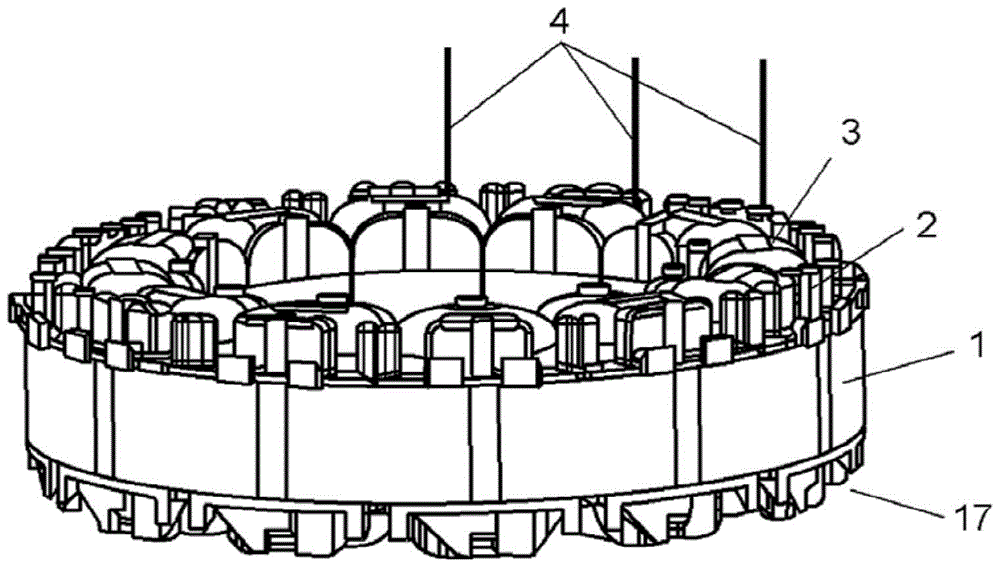

[0018] Hereinafter, embodiments of the present invention will be described using the drawings. figure 1 It is a configuration diagram showing a partial cross-section of the electric motor according to the embodiment of the present invention. figure 2 It is a figure which shows the concrete structural example of the winding completed product (finished stator) 17 of this electric motor. In this embodiment, an example of an electric motor, that is, a brushless motor that is installed in an air conditioner as an electric device and used to drive a blower fan will be described. In addition, in the present embodiment, an example of welding connection between the wire conductor and the terminal will be described. and, figure 2 The illustrated winding finished product 17 is constructed by using the winding stripping method of the motor winding of the present invention to peel off the insulating coating covering the tip of the wire. In addition, figure 1 The motor shown has such a wind...

Embodiment 1

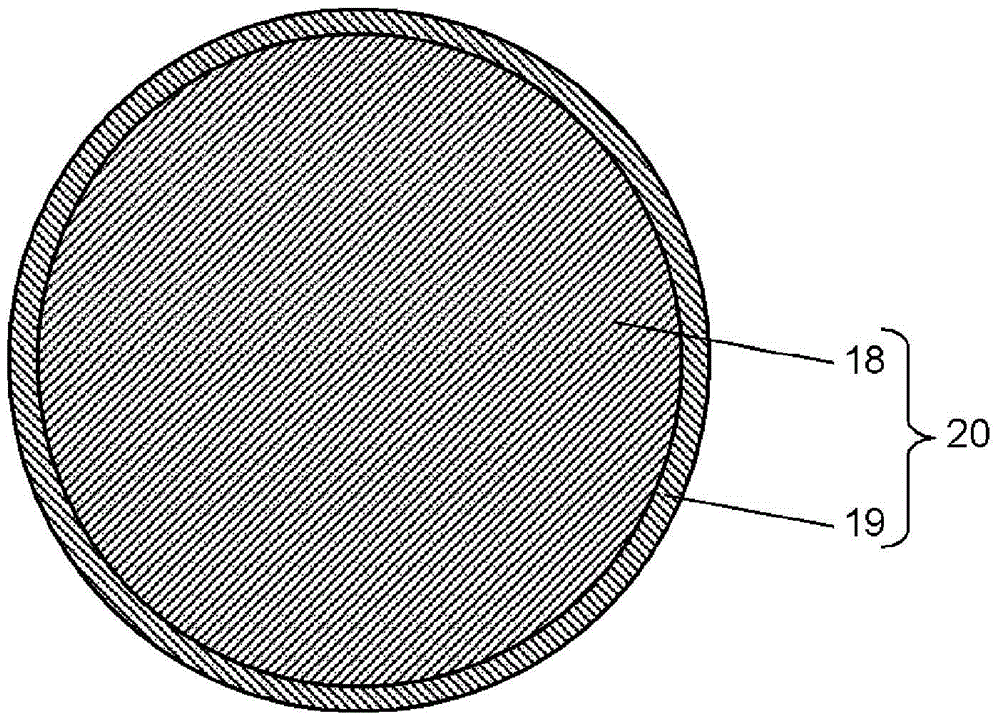

[0029] In the description of the embodiment, the following electric wire 20 is used: the conductor material is aluminum, the conductor diameter is 0.3 mm, the material of the insulation coating 19 is PEWN, and the insulation coating thickness is 0.012 mm. In addition, in the tension application direction acting on the winding end 4, a tension of 30 MPa was applied to the conductor of the electric wire and the cutting tool 101 was rotated at a rotation speed of 1500 r / min, thereby peeling off the insulating coating 19. At this time, the cutting tool movement direction 105 is the same as the tension application direction. In addition, the stopper for preventing the entry of the cutting tool 101 was adjusted to simultaneously peel off the portion of the conductor 18 with a depth of 0.002 mm. Under such conditions, the production of 1,000 motors was performed, and the defective rate of disconnection when the insulating coating was peeled off, the defective rate of residual insulati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com