Container, injection molding method of container, and mold for injection molding of container

A technology for injection molding and containers, which is applied in the field of containers, injection molding of containers and molds for injection molding of containers, which can solve the problems of gas leakage of the contents, decrease of air tightness, uneven contact pressure of sealing gaskets, etc., and achieve contact The effect of uniform pressure and high air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

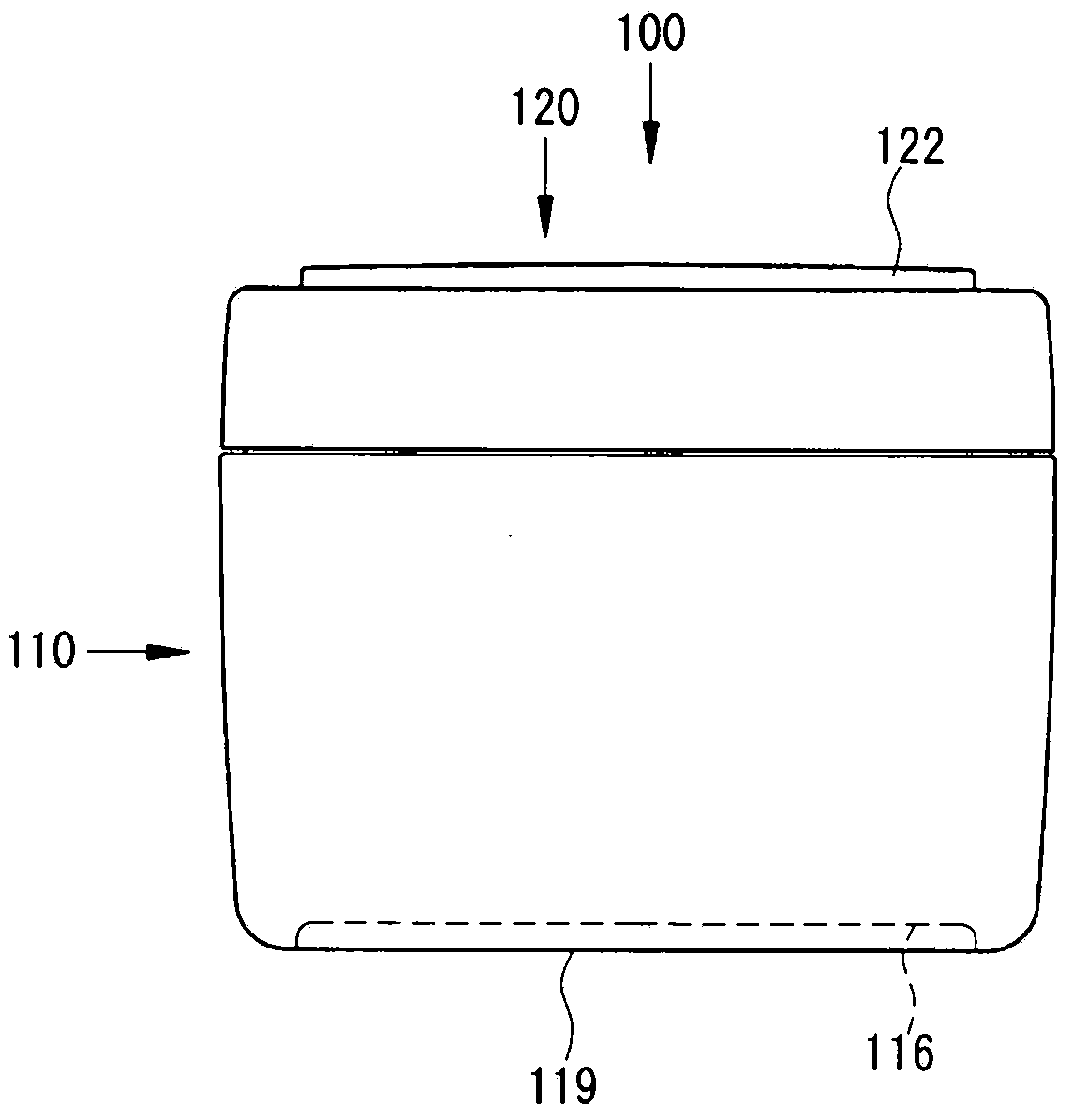

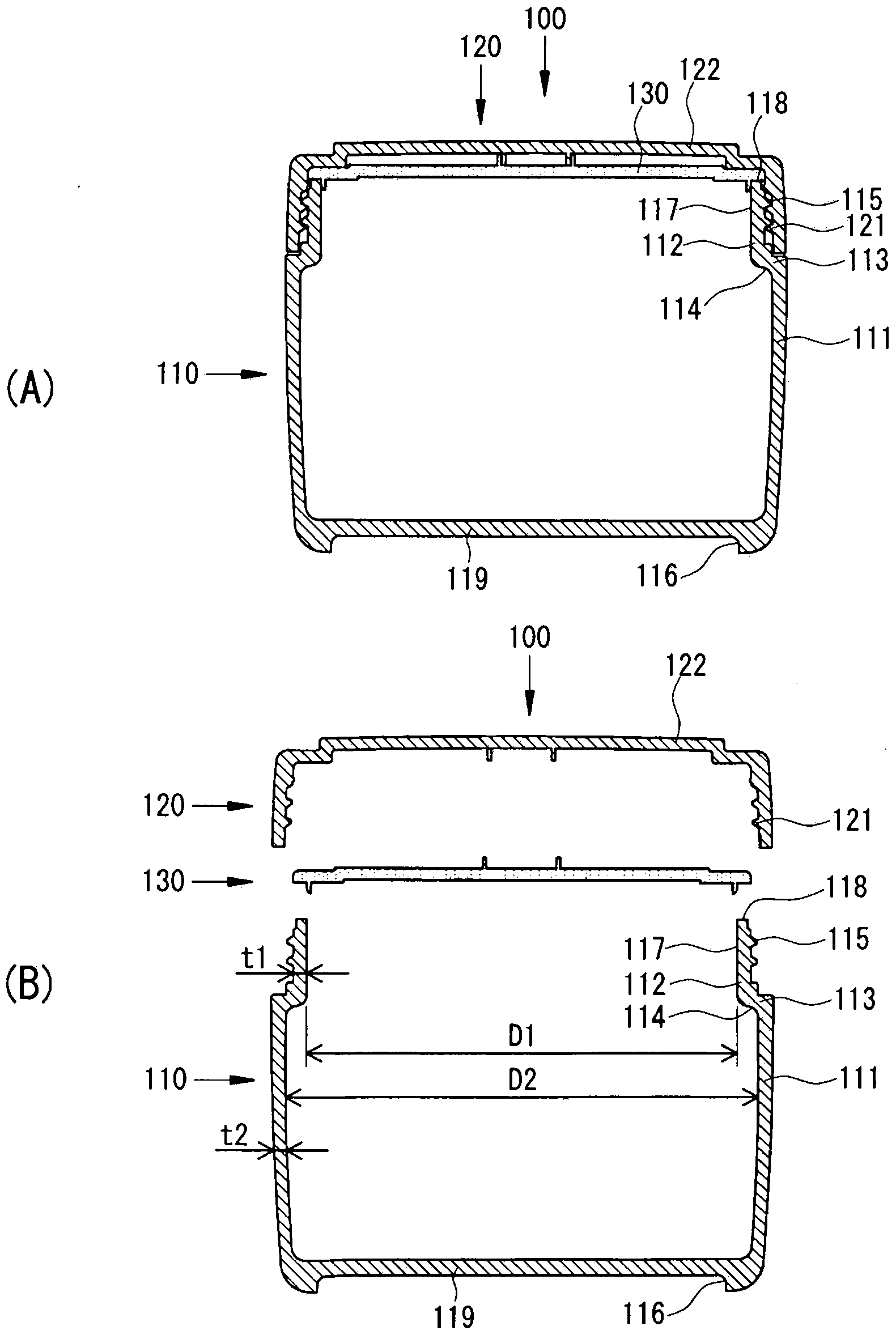

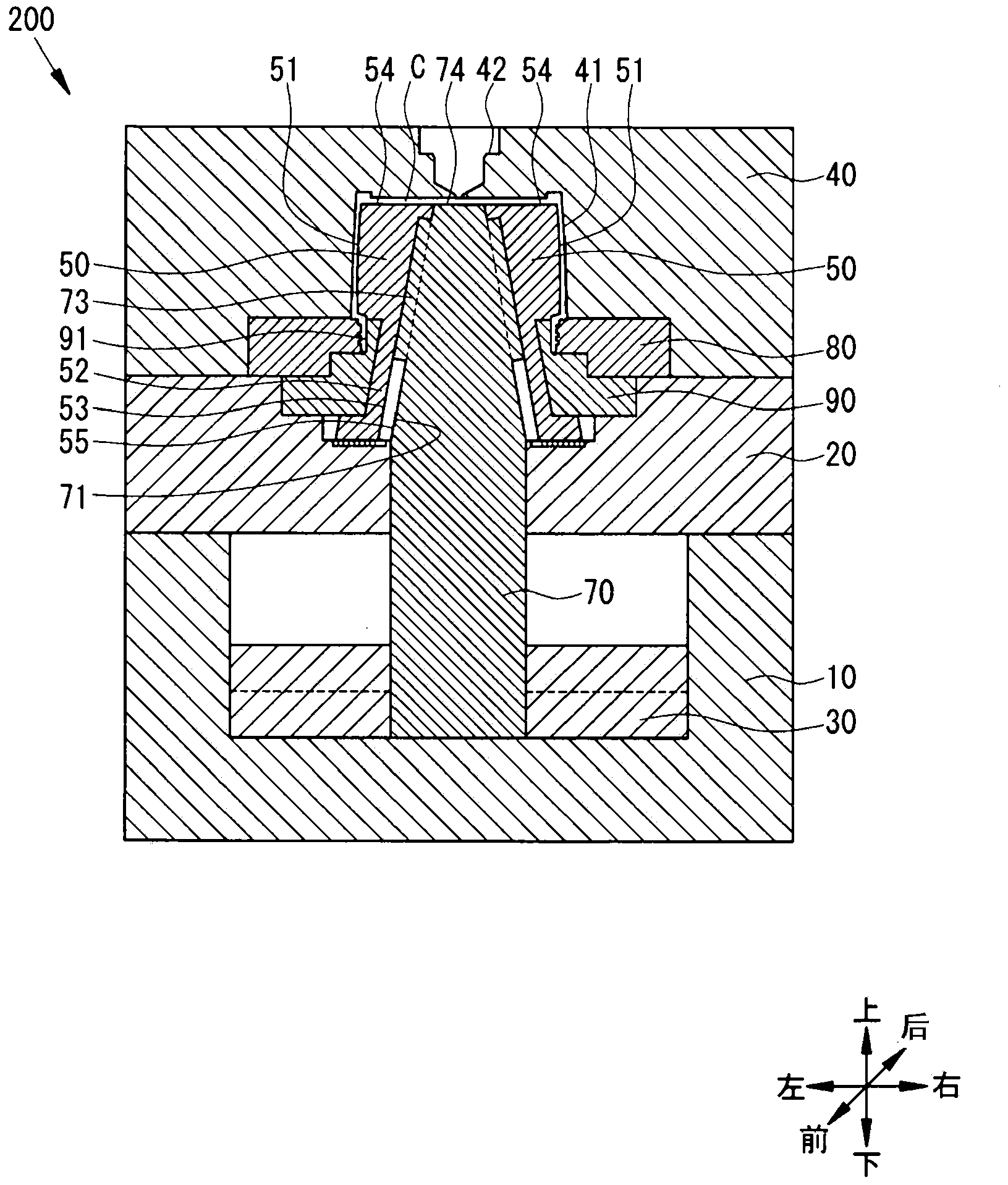

[0081] A container 100 as an example of an embodiment of the present invention, an injection mold 200 for injection molding the container body 110 of the container 100 , and an injection molding method will be described with reference to the drawings. First, use figure 1 The outline of the container 100 will be described.

[0082] Such as figure 1 , figure 2 As shown, the container 100 is a synthetic resin wide-mouthed container for filling cream-like cosmetic materials. The container 100 has a container body 110 , a lid portion 120 and a gasket 130 .

[0083] The container body 110 has a cylindrical portion 111 , a neck portion 112 and a shoulder portion 113 . The shoulder portion 113 is a portion where the outer diameter and inner diameter change from the neck portion 112 to the cylindrical portion 111 . On the inner peripheral surface of the shoulder portion 113 , an undercut 114 that changes from the inner diameter D1 of the opening 117 of the neck portion 112 to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com