Composite holographic image making method without laser plate making

A technology of holographic image and production method, which is applied in the field of synthetic holographic image production, and can solve problems such as complex production process, inability to meet personalized design, high production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but it is not intended to limit the present invention.

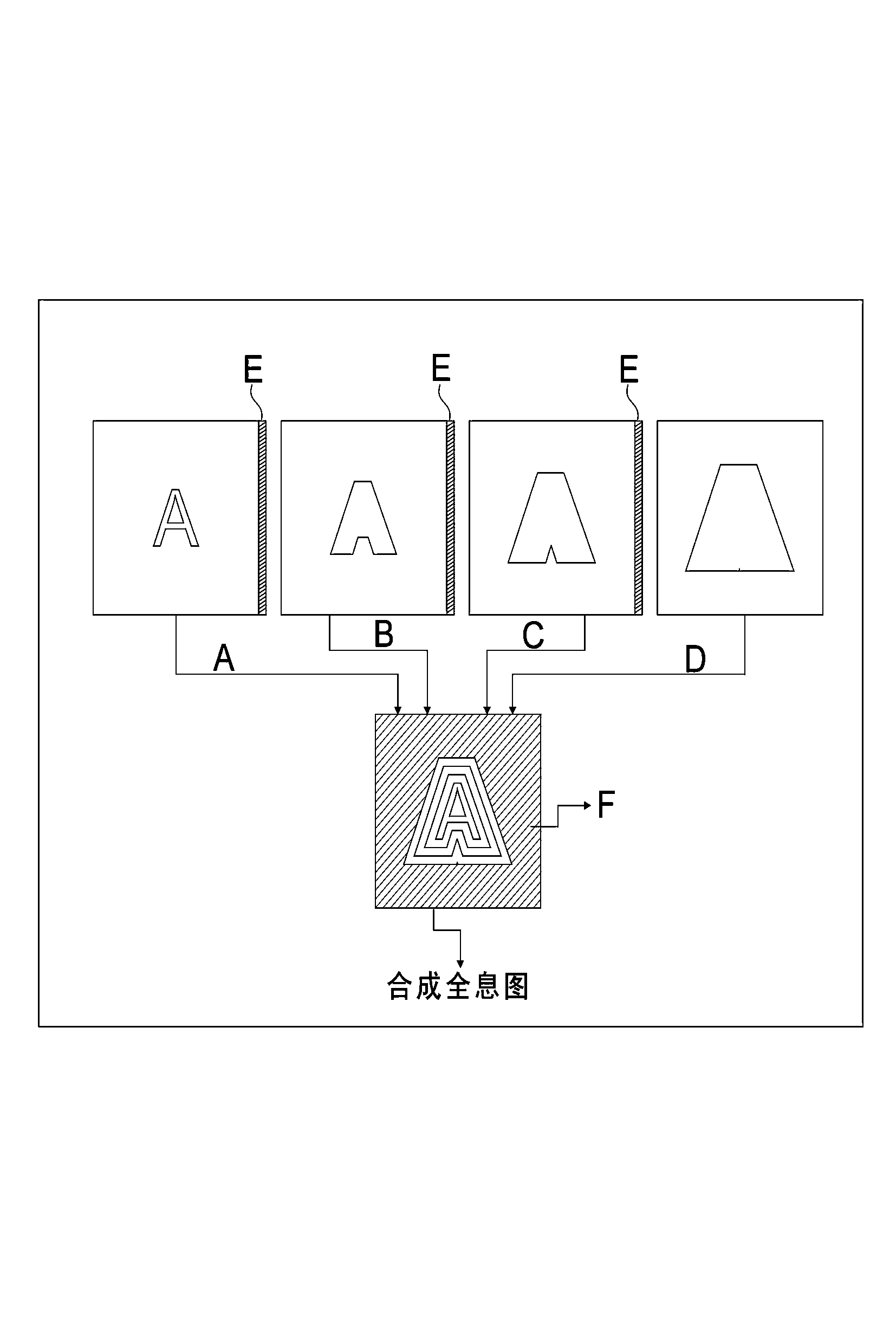

[0029] In an embodiment of the present invention, a method for making a synthetic holographic image without laser plate-making mainly includes the following steps:

[0030] The first step, combining, color-separates the picture and combines it with the plain grating holographic anodized aluminum film to form a color-separated holographic anodized aluminum film; it is worth noting that the plain grating holographic anodized aluminum film is a transparent and non-drying The plain grating holographic anodized aluminum film of the adhesive layer E;

[0031] The second step is to wash the aluminum. Place the color-separation holographic anodized aluminum film in a hydrofluoric acid solvent. Since hydrofluoric acid can chemically react with anodized aluminum, it can wash off the unp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com