Steel plate separation tool

A tool and steel plate technology, applied in the field of lifting equipment manufacturing, can solve problems such as damage to the upper surface of fixed-length steel plates, and achieve the effects of improving production safety performance, facilitating collection, and improving plate separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

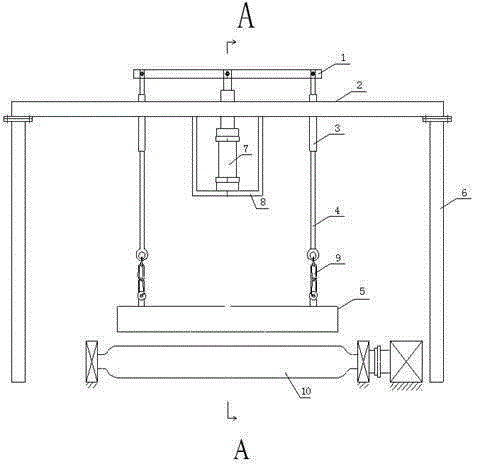

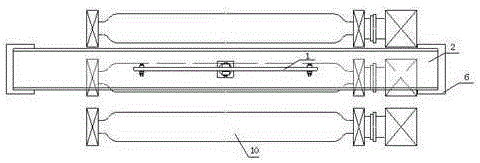

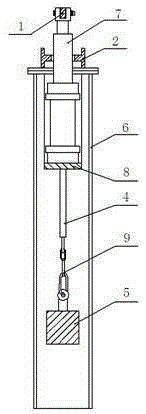

[0015] like Figure 1 to Figure 3 The steel plate separation tool shown includes a crossbeam 2 straddling the top of the transmission roller table. The crossbeam 2 is fixed on the upper part between two columns 6. A support frame 8 is connected to the lower end of the crossbeam 2. A hydraulic cylinder 7 is installed on the support frame 8. , the piston rod of the hydraulic cylinder 7 passes through the crossbeam 2 upwards, and the end of the piston rod of the hydraulic cylinder 7 is fixed with a balance rod 1; on the crossbeam 2, at least two vertical guide pipes 3 are fixed on both sides of the hydraulic cylinder 7 , the balance bar 1 is hung with a guide rod 4 slidingly matched with the guide tube 3, and a heavy electromagnet 5 is suspended above the transmission roller table through each guide rod 4; the lower end of the guide rod 4 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com