Drum-shaped stabilizer for drilling machine

A stabilizer, drum-shaped technology, applied in drill pipes, drill pipes, drilling equipment and other directions, can solve the problems of short service life of drill pipe stabilizers, shortened service life of enhanced sleeves, and increased operating costs of drilling rigs, etc., to achieve a stable effect. Good, increase the service life, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

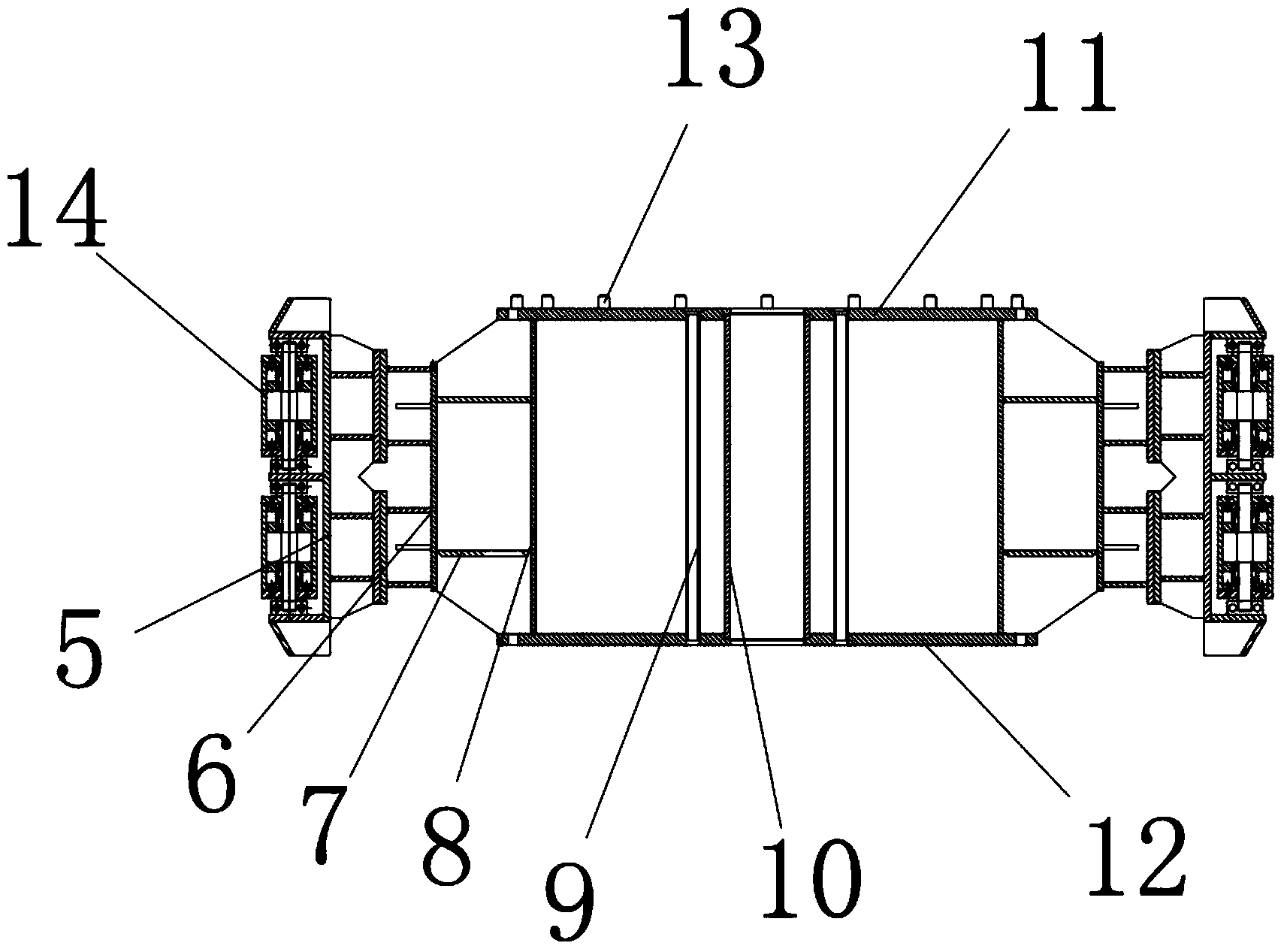

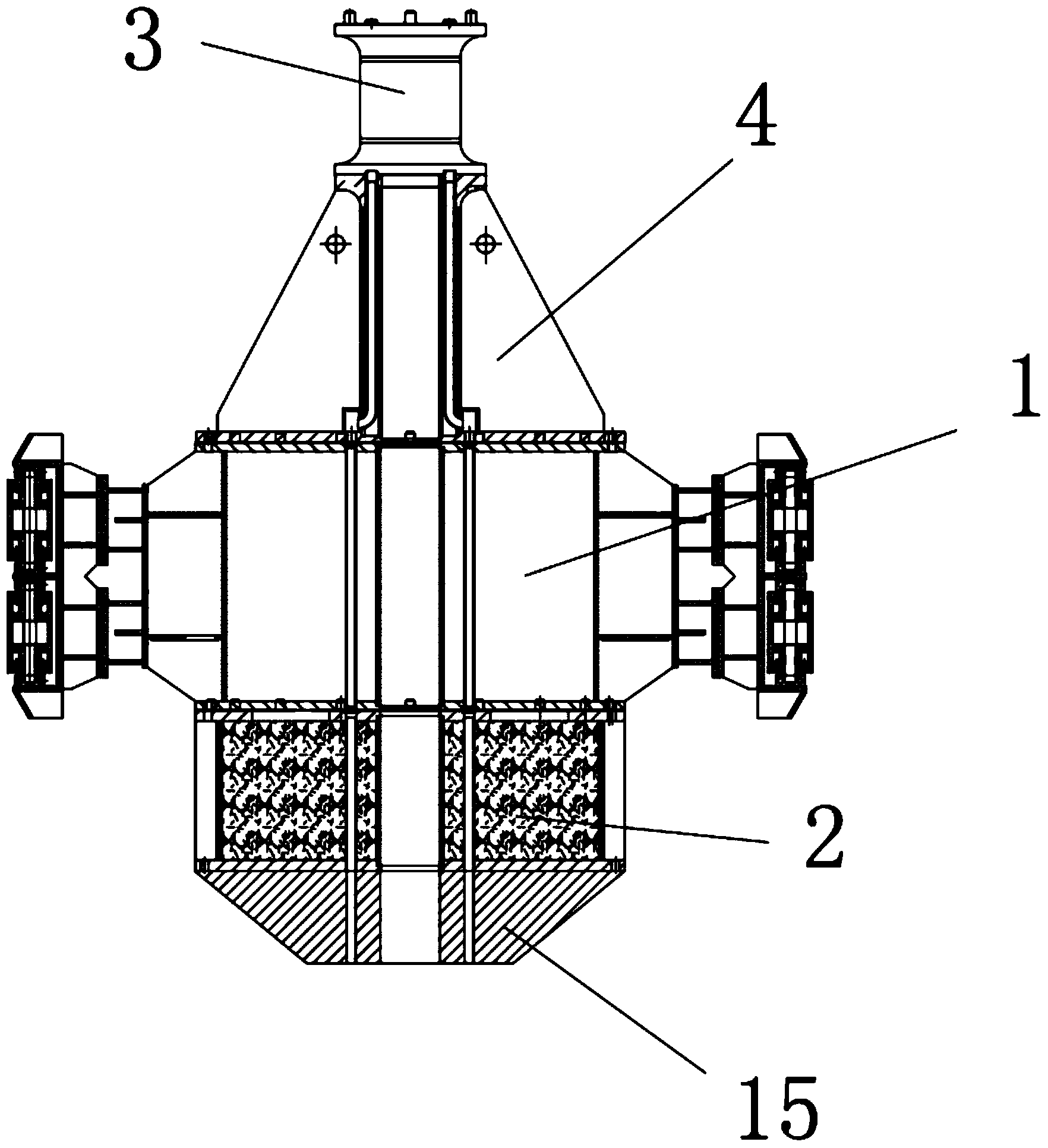

[0038] Install the variable-diameter short-connection 4 on the drum-shaped stabilizer 1, install the drill pipe 3 on the variable-diameter short-connection 4, and after filling the counterweight sand 24 in the counterweight 2, install the counterweight 2 on the drum-shaped stabilizer. On the lower end surface of the device 1, then a drill bit 15 is installed on the lower end surface of the counterweight 2, and then the drill rod 3 is connected to the lower end surface of the rotating device of the drilling rig, and the entire drill bit 15 is installed on the drilling rig together with the drum stabilizer 1, and then Turn on the drilling rig and start to work. During work, the construction department is filled with water to facilitate the drilling rig. The drill bit 15 is rotated to drill holes. The drill bit 15 is arranged with an air inlet pipe and a slurry discharge pipe, and the gas is passed through the drilling rig along the upper and lower edges. The air pipe 9 transports...

Embodiment 2

[0040] When the size of the drill bit of the drilling rig becomes smaller and cannot match the counterweight 2, it is necessary to change an assembly method, such as Figure 11 As shown, install the variable diameter short connection 4 on the drum stabilizer 1, install the drill pipe 3 on the variable diameter short connection 4, after the counterweight sand 24 is filled in the counterweight 2, the counterweight 2 is installed on the On the lower end surface of the drum-shaped stabilizer 1, an adapter 16 is installed on the lower end surface of the counterweight 2, and a drill bit 15 is installed on the lower end surface of the adapter 16, and then the drill rod 3 is connected to the lower end surface of the rotating device of the drilling rig , install the whole drill bit 15 together with the drum-shaped stabilizer 1 on the drilling rig, then turn on the drilling rig and start working, the rotating device drives the drill pipe 3 to rotate, and the rotation of the drill pipe 3 ...

Embodiment 3

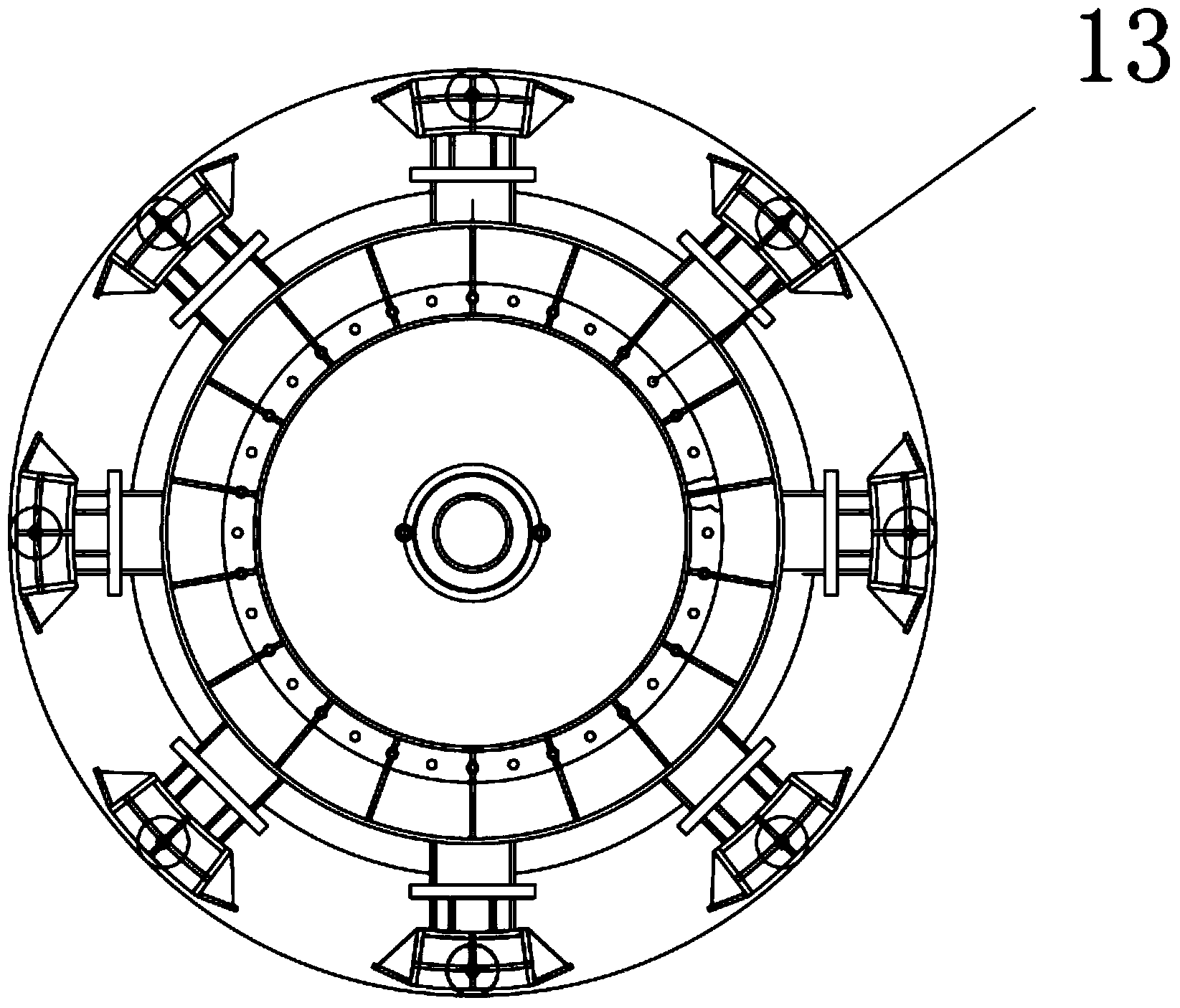

[0042] When the mounting hole of the drum stabilizer installed on the drilling rig is too large, an elastic telescopic connection or a cylinder connection can be installed between the outer cylinder 6 of the drum stabilizer and the roller bracket 5, so that the entire drum stabilizer The roller 14 leans against the inner wall of the mounting hole so that the drum stabilizer can work normally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com